Welding

1. Ensure that the workpiece is clamped down securely, is cleaned

and prepared for welding.

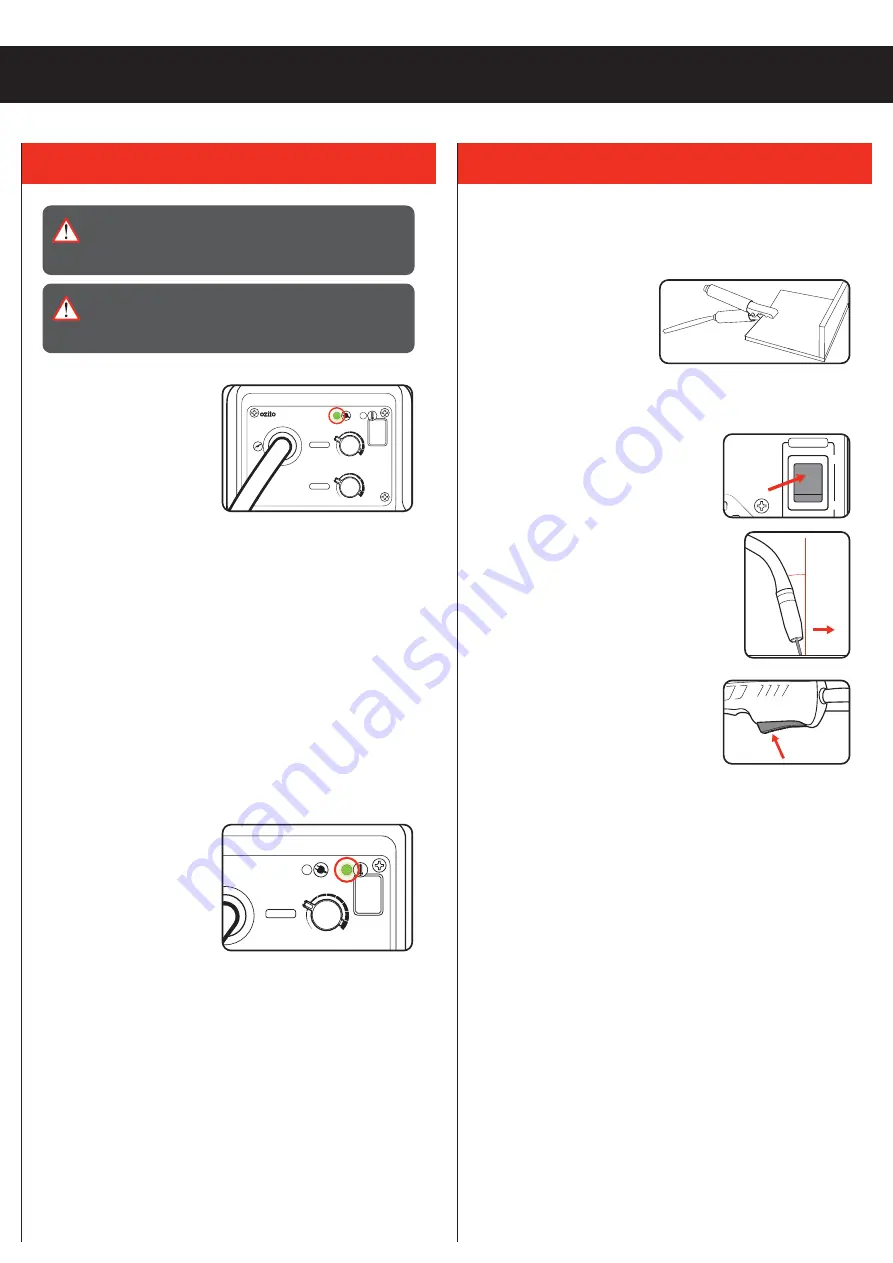

2. Attach the earth clamp to the

workpiece ensuring there is

good metal to metal contact.

Note:

Prior to connecting

the earth clamp it may be

necessary to clean the surface of the work piece using the metal

brush. Clamp it where it will not be in the way. This clamp provides

an earth connection back to the welder.

3. Switch the welder on and position the

welding mask in front of your eyes.

4. Position the wire tip approximately 8mm

from the workpiece at a 20° angle from the

vertical in the direction of movement.

Note:

Leaving a 10mm length of protruding

wire and holding the torch so that the wire

touches the workpiece is a good way to

estimate the proper placement.

5. Squeeze the torch trigger to start the

weld.

6. WELDING

5. INDICATOR LEDS

20

0

8mm

0

I

AC 240V ~ 50Hz

OFF

ON

AC POWER

Power LED Light

1. The ON LED illuminates

when the power cord is

connected to a live mains

outlet and the on/off switch

is in the on position.

Note:

The cooling fan will

operate when the unit is

switched on.

Thermal Overload Protection

All Welders have a feature called a duty cycle. Duty cycle on a

welder refers to the time in which the welder operates during

normal welding. A welder can only weld for a certain continuous

period of time before it requires to cool down.

If the internal components of the welder should become hot

the welder could overheat. If the welder overheats the Thermal

Overload Protection feature will automatically shut down the

welder.

THIS CAN OCCUR IN HEAVY USE AND DOES NOT INDICATE A

FAULT.

The Welder will cease to weld

and the Thermal Overload

LED light will turn on. This

LED indication light is just to

inform you that your welder is

becoming too hot and requires

a cool down to protect the

internal components of the

welder.

Do Not turn your welder Off as the welder has an internal cooling

fan and this will assist your welder to cool down quicker. Reducing

the cooling time will enable you to get back to your welding job

quicker.

Depending on how many Amps or how heavy the welding you are

doing the cooling time may take up to 10 minutes for your welder

cool down so you can return to your welding job.

Duty cycle % as referenced on the rating label are based on 10

minute intervals. For instance with a 20% duty cycle, one can weld

continuously for 2 minutes, but then must wait 8 minutes for the

welder to cool.

Lower current levels have longer duty cycles.

ON

THERMAL

OVERLOAD

ALLOW

WELDER

TO COOL

DOWN

!

100A

INVERTER

MIG WELDER

VOLTAGE

MIN

MAX

FEED RATE

MIN

MAX

ON

THERMAL

OVERLOAD

ALLOW

WELDER

TO COOL

DOWN

!

100A

INVERTER

MIG WELDER

VOLTAGE

MIN

MAX

FEED RATE

MIN

MAX

WARNING!

IF THE WELDER OVERHEATS & THE

THERMAL OVERLOAD PROTECTION ENGAGES,

DO NOT TURN OFF THE WELDER AS THE FAN WILL

ASSIST IN SPEEDING UP THE COOLING TIME.

WARNING!

ENSURE THE CLAMP & THE TORCH IS

AWAY FROM THE WELDING MATERIAL & PLACED

ON A NON-CONDUCTIVE SURFACE WHILE THE

OVERLOAD PROTECTION IS ENGAGED.