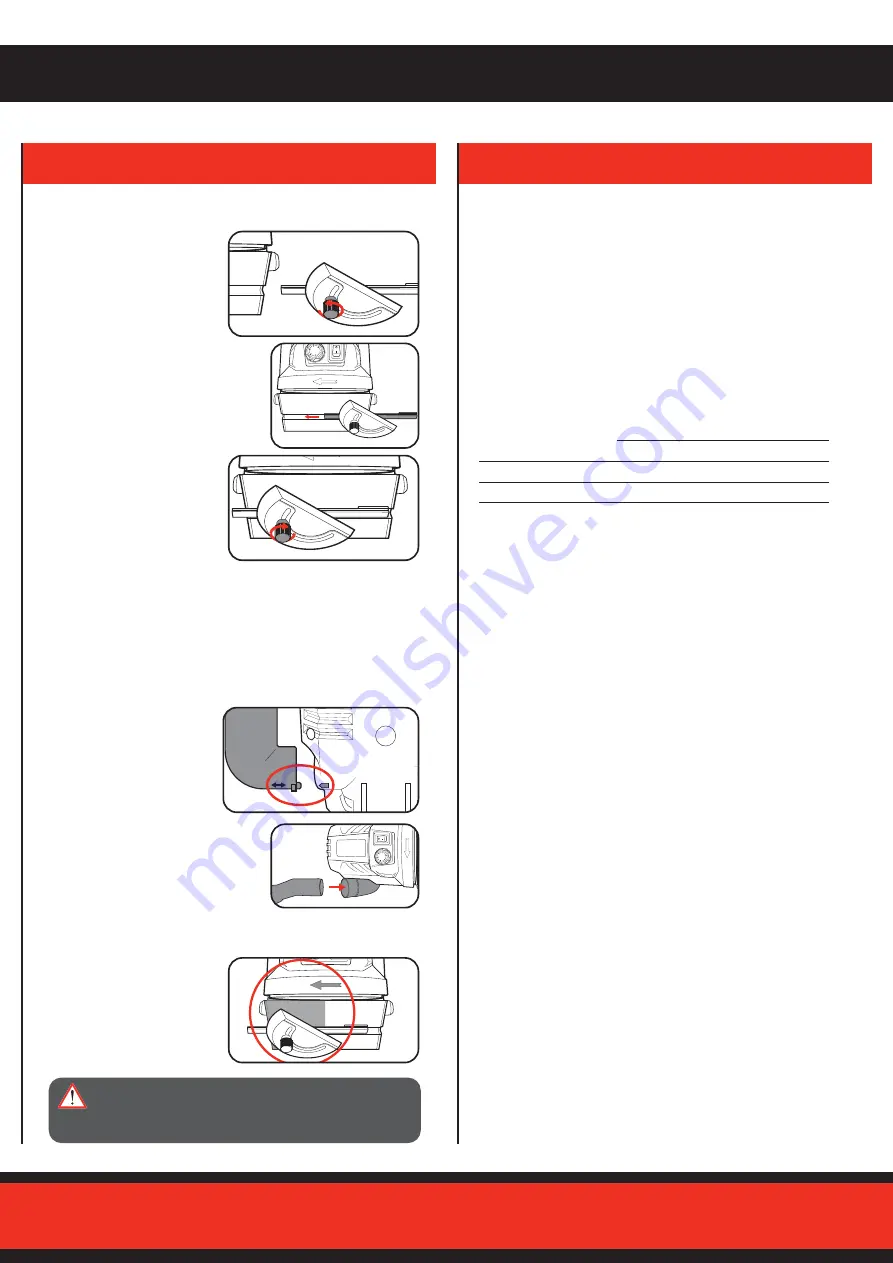

Installing The Mitre Fence

1. Loosen the fence adjustor

screw.

2. Slide the fence rail into the channel on

the tilt table.

3. Tighten the adjustor screw to

lock it in place.

Dust Extraction

A vacuum hose or dust extractor can be fitted to the dust extraction

port to help keep your work area clean while you’re sanding.

1. Align the arrow on the dust

extraction adaptor with the

arrow marking on the sander.

2. Insert the dust extraction

adaptor and turn it clockwise

to lock it in place.

3. A vacuum hose can now be fitted to

the other end of the adaptor to remove

sanding dust and debris as you work.

4. To remove the adaptor, rotate it in the port until the arrow markings

align, then pull it out of the slot.

Note:

The saw dust will travel

according to the direction of

the wheel rotation. For efficient

dust extraction, position the

workpiece on the left of the

sanding disc.

WARNING!

DUST EXTRACTION SHOULD NOT BE

USED DURING METAL SANDING TO PREVENT HOT

METAL FRAGMENTS FROM ENTERING THE VACUUM

CLEANER OR DUST EXTRACTION SYSTEM.

Sandpaper Selection

Selecting the correct grit of sandpaper is an important step in

achieving optimum results. Coarse grit will remove the most material.

Finer grit will produce a smoother finish. The condition of the

workpiece will determine the grit of the sandpaper to be used. The

higher the grit number, the finer the grade of sandpaper.

If the surface is rough, start with a coarse grit and sand until the

surface is uniform. Medium grit may then be used to remove

scratches left by the coarser grit. Finer grit is then used to finish the

surface. Always continue sanding with each grade of sandpaper until

the surface is uniform.

MATERIAL

APPROPRIATE GRIT

Coarse Sanding

Fine Sanding

Soft Timbers

60

240

Hardwoods

60

180

Note:

If intermediate sanding is required, choose a grit rating

between coarse and fine. The above table is intended as a guide

only. To ensure a satisfactory result, test on a scrap piece of material

to ensure the grit of sandpaper chosen is suitable for the desired

finish.

Replace the sand paper when it becomes worn.

2. FITTING SANDPAPER