3

ONLINE MANUAL

Scan this QR Code with your

mobile device to take you to

the online manual.

Remove the bench grinder and contents from within the carton.

Sit the bench grinder down on a table or bench with the switch side

facing towards you.

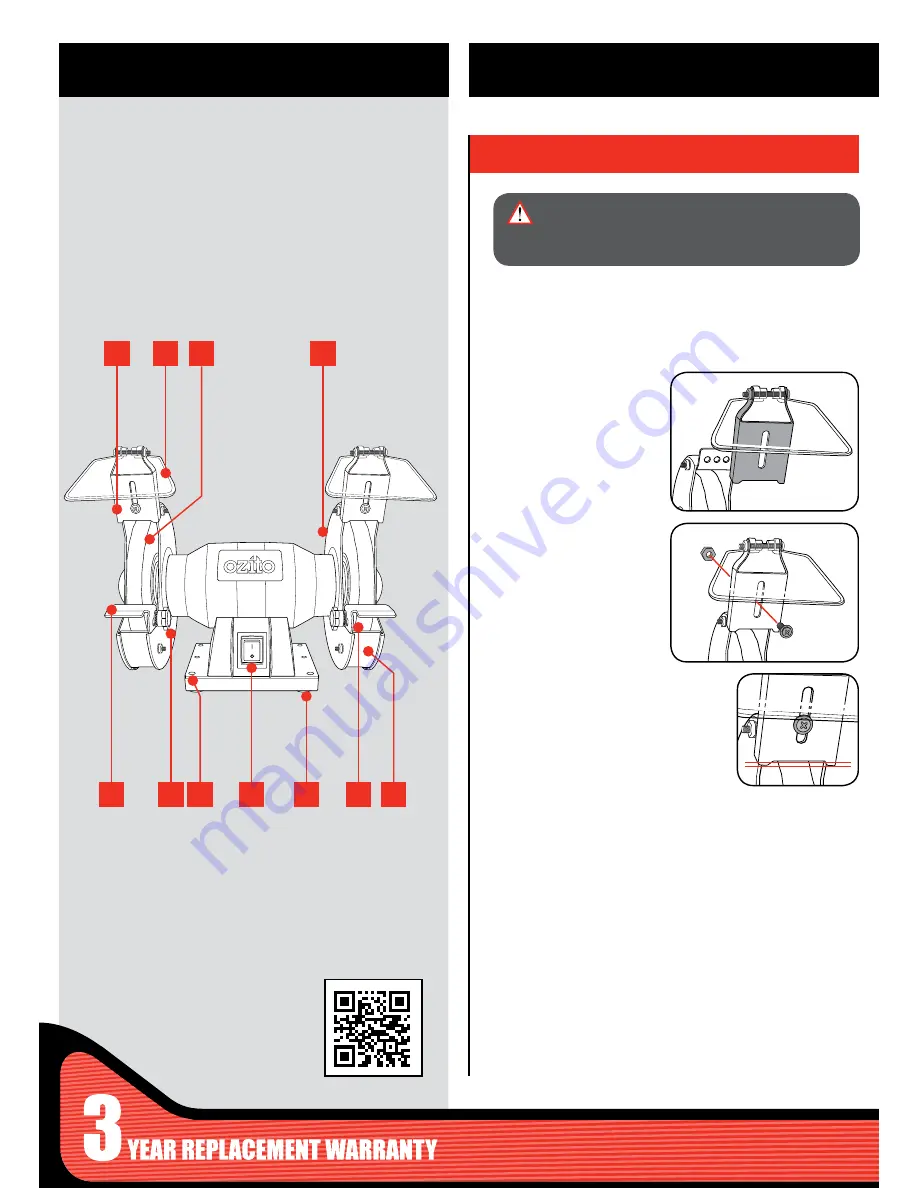

Fitting the eye shields

1. Assemble the eye shields

by placing the raised metal

sides of the eye shield

bracket onto the upper

wheel guard. Align the

central hole in the upper

wheel guard with the slot in

the eye shield bracket.

2. Fix the eye shield bracket

to the upper wheel guard

using the screws supplied

with a flat washer and

spring washer. Fasten in

place with a nut at the rear

of the upper wheel guard.

3. Adjust the eye shield using the adjusting

screw so that the distance between the

grinding wheel and the eye shield bracket

is as small as possible and does not

exceed 2 mm.

Note:

Adjust the eye shields periodically

to compensate for wear on the grinding wheels.

1. Eye Shield Bracket

2. Eye Shield

3. Grinding Wheel

4. Wheel Guard

5. Tool Rest

6. Tool Rest Adjusting Knob

7. Mounting Hole

8. On/Off Switch

9. Rubber Foot

10. Tool Rest Bar

11. Wheel Guard Cover

bENCH GRINDER

KNOW YOUR PRODUCT

2

3

4

1

1. ASSEMBLY

SETUP & PREPARATION

5

6

8

9

10 11

7

WARNING!

TURN OFF THE bENCH GRINDER

AT THE MAINS OUTLET AND UNPLUG bEFORE

ATTEMPTING ASSEMbLY. FAILURE TO DO SO MAY

CAUSE SERIOUS PERSONAL INjURY.

2 mm

Max.