CARING FOR THE ENVIRONMENT

Tools that are no longer usable should not be disposed of with

household waste but in an environmentally friendly way. Please

recycle where facilities exist. Check with your local council

authority for recycling advice.

Recycling packaging reduces the need for landfill and raw

materials. Reuse of recycled material decreases pollution in the

environment. Please recycle packaging where facilities exist.

Check with your local council authority for recycling advice.

Chain Replacement:

The chain can be purchased through Ozito spare parts or from your

local Bunnings Warehouse. The correct chain can be purchased by

matching the pitch, gauge and number of links as shown below:

SPARE PARTS

DESCRIPTION OF SYMBOLS

cc

Cubic Centimeters (the standard measure of displacement in Europe and Asia)

n

o

No load speed

/min

Revolutions or reciprocation per minute

dB

Decibel level

Read the manual prior to use

Wear safety boots

Wear safety gloves

Warning

Be aware of moving branches

Pull recoil starter to start motor

Do not use chainsaw when

only holding with one hand

Use both hands when using chainsaw

Use eye, ear, head and breathing

protection when operating the chainsaw

Fuel inlet

On/Off

(Position: next to throttle trigger)

Setting the On/Off switch to Off,

stops the engine immediately

Choke control

(Position: above priming bulb)

Chain brake released (hollow arrow) and activated (solid arrow)

(Position: right side of machine, on chain drive cover)

CHOKE Start position (when engine is cold)

RUN Run position

Chain oil inlet

H

High run adjustment screw

L

Low run adjustment screw

T

Idel adjustment screw (Position: left side of

machine close to pull start handle)

Regulator compliance mark

outward

stroke

30

0.6mm

MAX

MIN

0.6mm

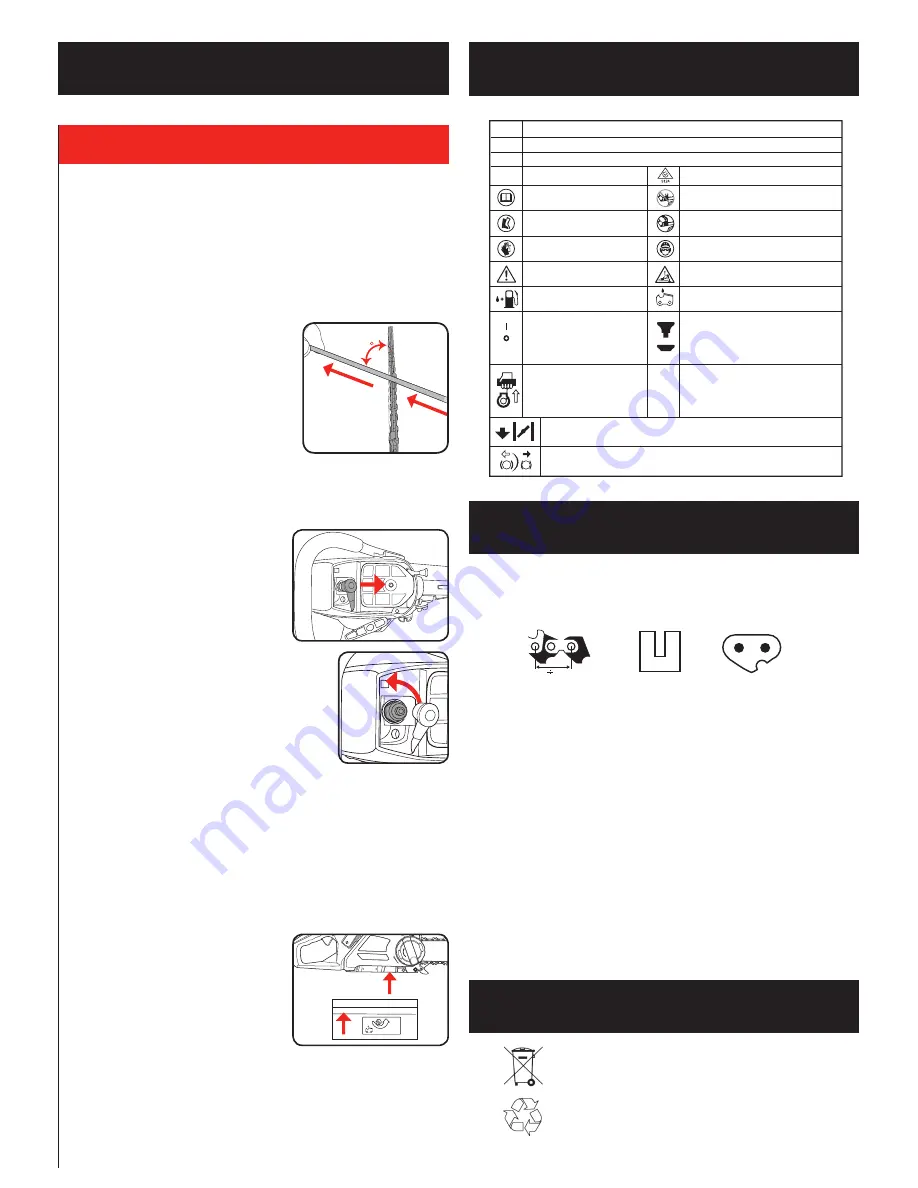

Chain Sharpening

Sharpen the chain using protective gloves and the round file supplied.

Sharpen the chain regularly to maintain optimum performance of the

saw. Signs of a dull chain are:

• The sawdust becomes powder-like

•

Extra force is required to execute a cut

•

The cut does not track in a straight line

•

Increased vibration

Sharpen each cutter using a chain file.

Always use outward strokes and maintain

a 30° angle between the chain and file.

After sharpening, the cutters must all

have the same width and length.

After every 3–4 uses get an authorised

repair centre to professionally sharpen

your chain. They have the special tools

necessary to ensure the correct cutting

angles and depths.

Replacing the spark plug

When the chainsaw will not start and everything has been checked,

it is likely the spark plug will need replacing. The spark plug is not

covered under warranty.

To replace the spark plug:

1. Loosen the filter cover knob and

remove the filter cover.

2. Pull the spark plug lead off the spark

plug end.

3. Loosen (anti-clockwise) the spark

plug using the larger socket side of the socket

wrench provided.

4. Remove the spark plug and replace with a new

one, as specified.

Spark plug types:

LD L8RTF, NGK BPMR7A, Champion RCJ7Y.

5. Secure the spark plug in position by tightening (clockwise) the

spark plug using the socket wrench provided.

6. Fix the spark plug lead back to the end of the spark plug ensuring

it clicks into place.

7. Replace the filter cover and secure in place with the filler cover

knob.

Adjusting the Automatic Oil Feed System

It is possible to adjust the flow rate of

the chain bar oil if it is not supplying a

sufficient quantity of oil to the chain.

1. Turn the saw onto its side.

2. Using the screwdriver provided,

adjust the oil feed by rotating

clockwise to decrease the flow of oil,

or rotating anti-clockwise to increase

the flow of oil.

3. Test the operation of the automatic oil feed system to ensure

sufficient oil is being supplied to the chain. (Refer to the

“

Operation

” section overleaf for instructions on how to test

automatic oil feed system.)

2

9.53

mm

(3/8)

1.3

mm(

.050”)

57

Links

2

2

Spare parts can be ordered from the Special Orders Desk

at your local Bunnings Warehouse.

For further information, or any parts not listed here, visit

www.ozito.com.au or contact Ozito customer service

Australia 1800 069 486

New Zealand 0508 069 486

E-mail: enquires@ozito.com.au