2. SAW ALIGNMENT

45

0

30 0

150

00

15

0

30

0

45

0

20

40

50

60 100 120 140 160 180

90

0

Rear Fence

Blade

45

0

30 0

150

00

15

0

30

0

45

0

20

40

50

60 100 120 140 160 180

45

0

30

0

15

0

0

0

15

0

30

0

45

0

20

40

50

60 100 120 140 160 180

Blade Bolt

Washer

Outer Flange

Blade

Inner Flange

Spindle

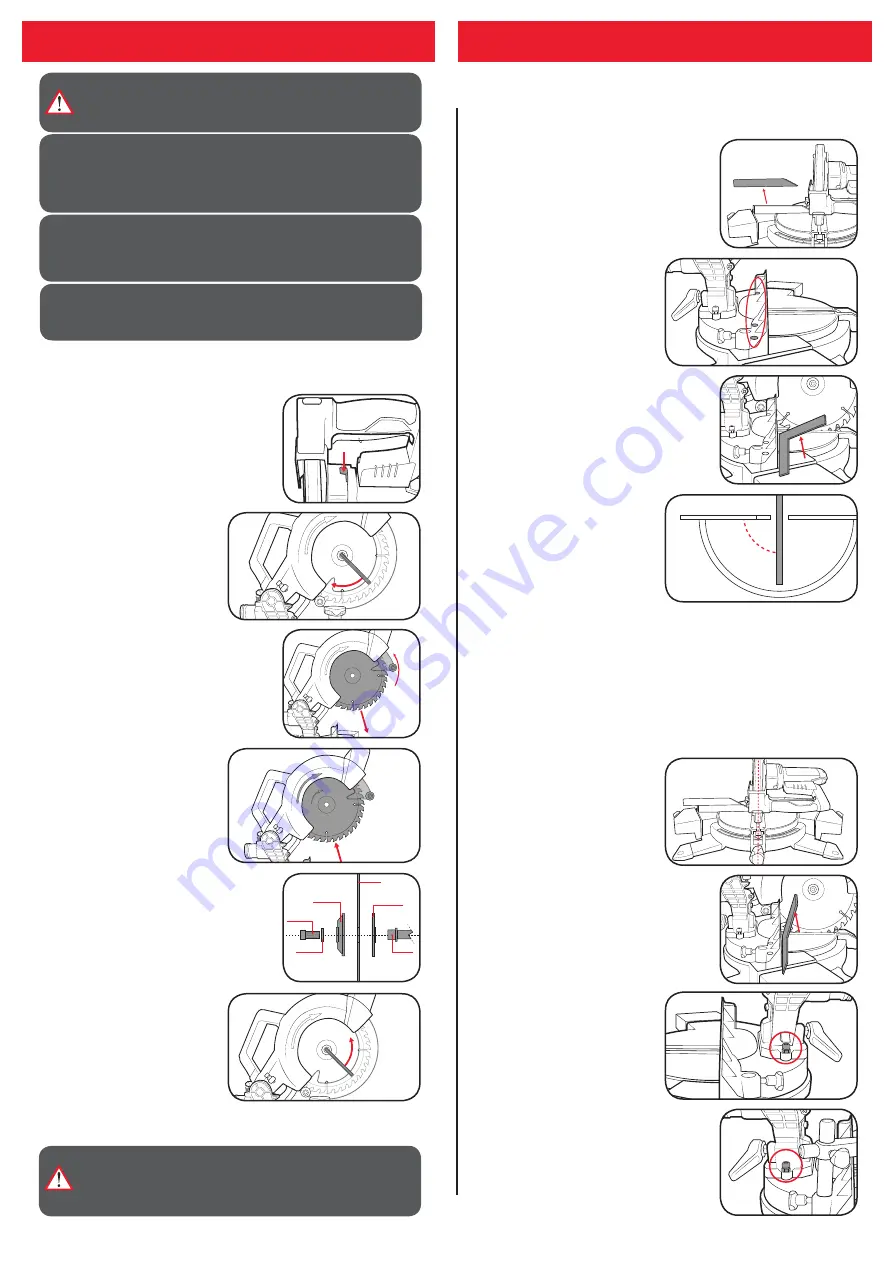

Fence Alignment

Bevel Alignment

2 Loosen slightly all 4 hex

bolts securing the rear fence

in place.

2 Once the spindle lock stops

the blades rotation, rotate

the blade bolt clockwise to

remove the bolt and outer

flange.

6 Depress the spindle lock and

then tighten the blade bolt

using a hex key in an anti-

clockwise direction.

4 Install the new the blade over

the spindle and onto the inner

flange.

Note:

Ensure the blade is fitted

so that the arrow on the blade

matches the same direction as

the arrow on the guard.

1 Set the bevel angle to 0°,

lock the cutting head down

and loosen the bevel locking

lever.

3 Loosen the right bump

stop nut and adjust the

screw until the blade is

perpendicular with the table.

Then tighten the nut to

secure in position.

4 Gently tap the fence into

position so that the fence is

perfectly perpendicular to

the blade.

Retighten the bolts.

1 Set the mitre angle to 0°, lock the cutting

head down and remove the upper rear

fence by loosening the fence locking knob

all the way out.

1 Ensure the cutting head is raised. Press

the spindle lock button in while rotating

the blade clockwise using a hex key in the

central blade bolt.

5 Fit the outer flange by placing the cupped

side against the blade followed by the

washer and blade bolt.

Make sure the lower guard operates smoothly and properly protects you from

the blade before using the saw.

3 Raise the lower blade guard and remove

the blade from the spindle.

Note:

Make sure the inner flange stays in

place on the spindle.

The saw has 2 bump stops that limit the bevel angle to 0° and 45°. If the

bevel angle becomes inaccurate, these stops can be readjusted by following

the steps below.

3 Lay a carpenters square on the table with

one edge along the blade and the other

along the fence. Any inaccuracy should be

visible.

Note:

The square must contact the blade,

not the teeth, for an accurate reading.

2 Lay a carpenters square along the table

with one edge along the blade. Any

inaccuracy should be visible.

Note:

The square must contact the blade,

not the teeth, for an accurate reading.

4 Repeat steps 2 and 3 for the left bump

stop using a 45° angle carpenters triangle.

5 Make a test cut and repeat this process until the fence is adjusted

accurately. Then you can reattach the upper rear fence.

The mitre saw should be set-up fairly accurate out of the box, but if the saw

becomes misaligned, you can follow the instructions below to adjust the tool.

1. CHANGING THE BLADE

The tool is recommended for wood cutting only and is not recommended

for use with abrasive wheels or masonry/diamond cutting wheels. Only use

210mm wood cutting blades.

WARNING!

ENSURE THE TOOL IS SWITCHED OFF AND

DISCONNECTED FROM THE POWER SUPPLY BEFORE

PERFORMING ANY OF THE FOLLOWING TASKS.

CAUTION!

NEVER TRY TO USE A BLADE THAT IS LARGER

THAN THE STATED CAPACITY OF THE MITRE SAW. IT MIGHT

COME INTO CONTACT WITH THE BLADE GUARDS AND RISK

PERSONAL INJURY OR DAMAGE TO THE MITRE SAW. THIS

WILL NOT BE COVERED UNDER WARRANTY.

CAUTION!

ENSURE THAT THE CORRECT BLADE BUSH THAT

MAY BE REQUIRED SUITS THE SPINDLE AND BLADES THAT

ARE FITTED.

CAUTION!

NEVER USE A BLADE THAT IS TOO THICK TO

ALLOW THE OUTER FLANGE TO ENGAGE WITH THE FLATS ON

THE SPINDLE. IT WILL PREVENT THE BLADE SCREW FROM

PROPERLY SECURING THE BLADE ONTO THE SPINDLE.

WARNING!

TO ENSURE THE CORRECT BLADE ROTATION,

ALWAYS INSTALL THE BLADE WITH THE BLADE TEETH

POINTING DOWNWARDS. ENSURE THE ARROW

DIRECTION ON THE BLADE CORRESPONDS WITH THE

ARROW ON THE UPPER BLADE GUARD.

0318