ONLINE MANUAL

Scan this QR Code with your

mobile device to take you to

the online manual.

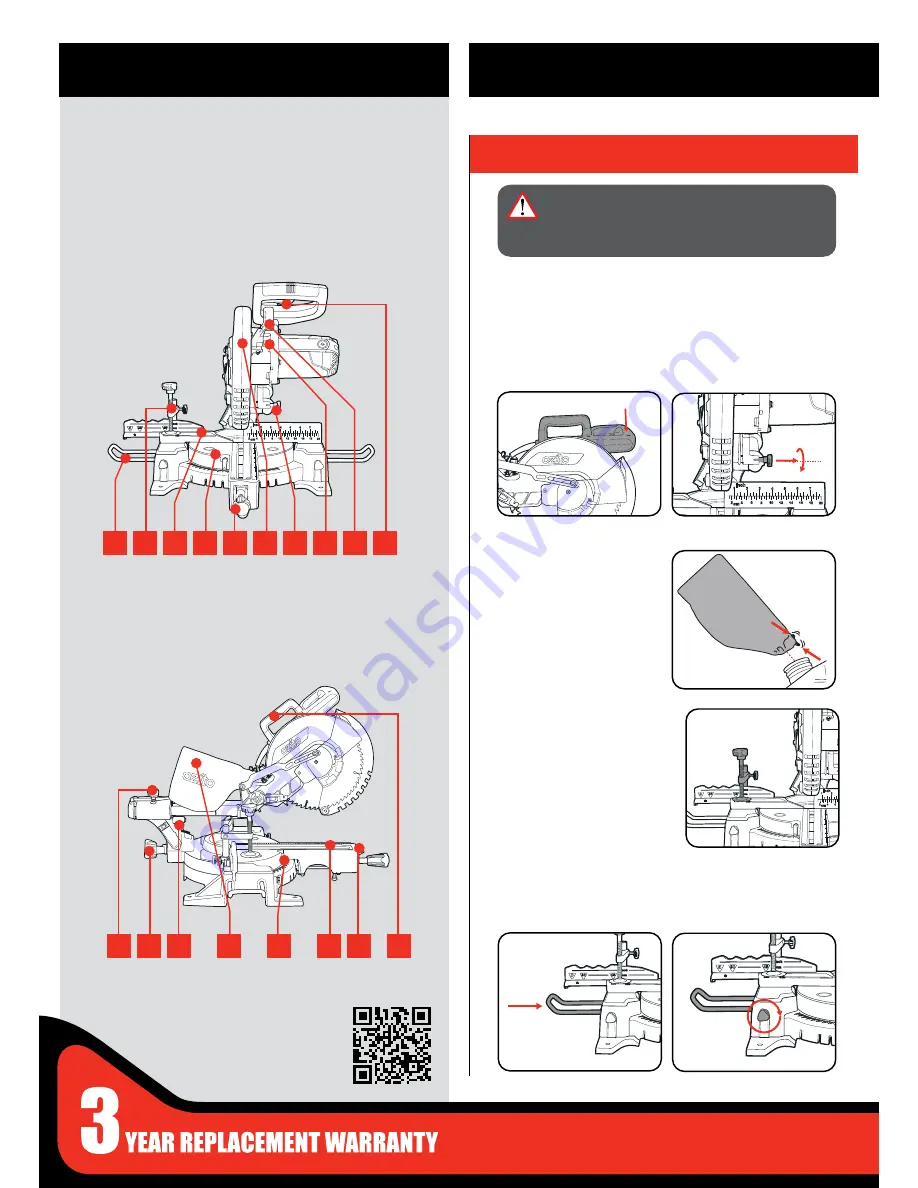

1 Material Support Bar

2 Material Clamp

3 Fence

4 Mitre Table

5 Mitre Table Lock

6 Retractable Safety Guard

7 Lock Down Pin

8 Spindle Lock Button

9 Release Lever

10 Trigger

MITRE SAW

KNOW YOUR PRODUCT

1. ASSEMBLY

1. Remove foam packaging materials and using the carry handle,

carefully lift the mitre saw from its box and place it on a level

work surface.

1. Squeeze the clamp at the

end of the dust bag, place

over the dust extraction

port.

1. Insert each bar into the

two holes located on

both sides of the base.

2. Release cutting head from its transport position. While holding

the head of the saw down release the lock down pin by rotating

it 90 degrees.

11 Slide Lock

12 Bevel Lock

14 Dust Bag

13 Laser Guide

15 Mitre Angle Pointer

16 Table Insert

17 Mitre Release

18 Carry Handle

SETUP & PREPARATION

Unpacking

Material Support Bars

Dust Bag

WARNING!

ENSURE THE TOOL IS SWITCHED

OFF AND DISCONNECTED FROM THE POWER

SUPPLY BEFORE PERFORMING ANY OF THE

FOLLOWING PROCEDURES.

2. Tighten screw when in

place.

Material clamp will assist

securing timber when making

cuts.

Note:

The clamp can be

mounted on either the left or

right side of the blade.

Material Clamp

1

11 12 13

14

15

16 17 18

2 3 4 5 6 7 8 9 10