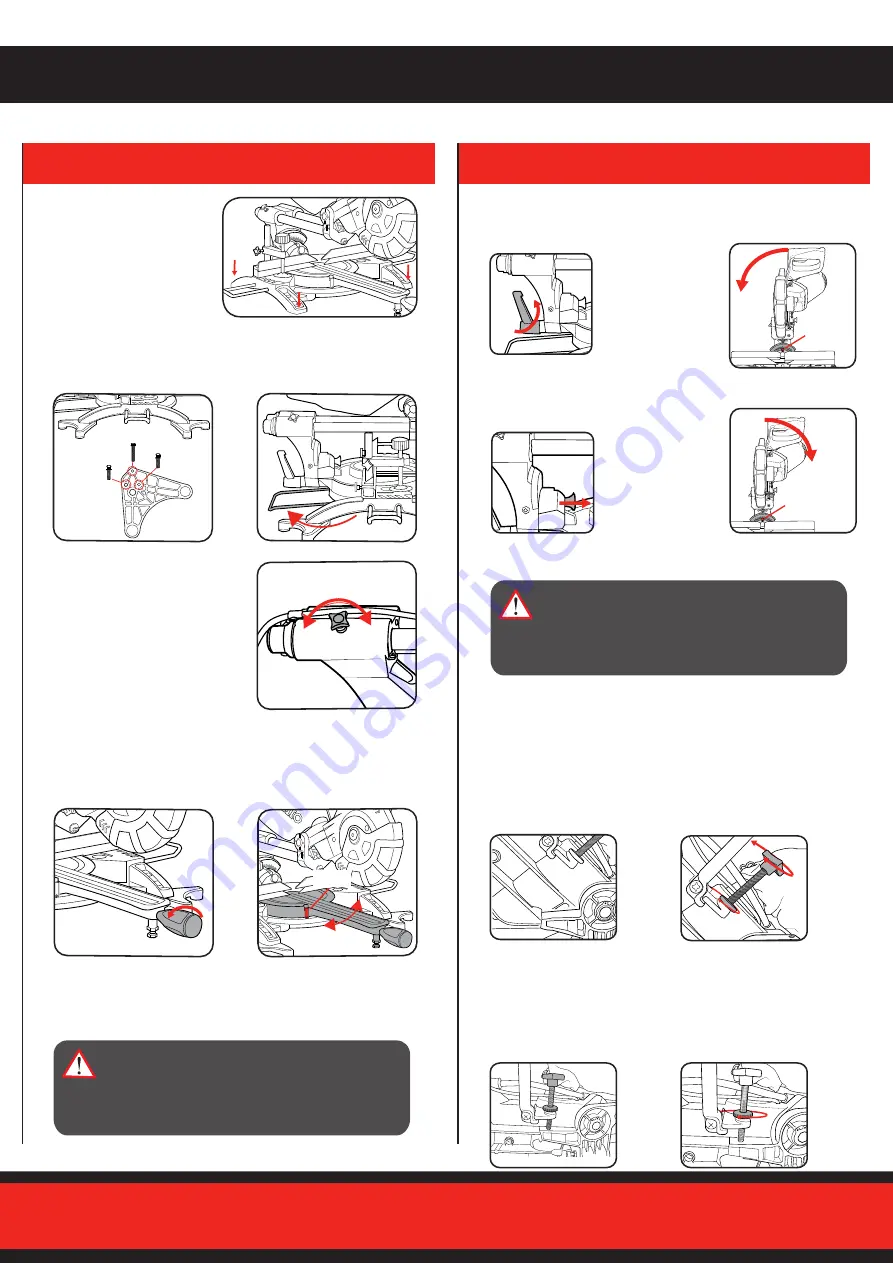

2. SET-UP AND ADJUSTMENTS

1. Loosen mitre

table lock

2. Rotate the mitre table to the

desired mitre angle (left or

right) as shown by the mitre

angle pointer

Mitre Angle Adjustment

MITRE ANGLE

POINTER

3. Tighten mitre table lock at selected angle

Bevel Angle Adjustment

3. Tighten bevel lock at selected angle

Note:

The mitre table features positive click stops at 0°, 15°, 22.5°,

31.6° and 45° for quick setting of common mitre angles.

Bench Mounting

The base of the saw has four

bench mounting holes (1 each

corner) that can be used to

mount it to a workbench or

mitre saw stand. Use four

screws or bolts (not included)

to secure.

WARNING!:

ENSURE THE MITRE TABLE LOCK

IS TIGHT BEFORE MAKING A CUT. FAILURE

TO DO SO MAY RESULT IN THE MITRE TABLE

MOVING DURING OPERATION AND CAUSE

SERIOUS PERSONAL INJURY.

WARNING!:

ENSURE THE BEVEL LOCK IS

TIGHT BEFORE MAKING A CUT. FAILURE TO

DO SO MAY RESULT IN THE CUTTING HEAD

MOVING DURING OPERATION AND CAUSE

SERIOUS PERSONAL INJURY.

Trenching refers to restricting the depth of cut and permits a “trench”

to be cut in the workpiece.

Bevel Angle Adjustment

Trenching

1. Ensure the cutting head is

raised, move the trenching

stop to the right as far as it

will go.

2. To adjust the trenching

depth rotate the trenching

depth adjustment screw.

3. To check that the blade

stops at the desired position,

lower the cutting head

until the trenching stop

adjustment screw touches

the trenching stop.

4. When the correct depth is

set. Lock it in position using

the trenching depth lock nut.

Slide Lock

When cutting a narrow piece of

wood it is not necessary to use

the slide mechanism. In these

circumstances, push back the

cutting head and ensure the slide

locking knob is tight to prevent the

cutting head from sliding.

To ensure the saw is standing securely when not mounting to a

workbench or mitre saw stand. Screw the Additional Support Feet

to the feet of the mitre saw with the fasteners provided. Then swing

out the Stabilising Bar to the rear until it engages.

18mm

18mm

30mm

1. Loosen bevel

lock.

2.

BEVEL LEFT

- Tilt the cutting head

to the desired

bevel angle

left as shown

by the bevel

angle pointer.

2a.

BEVEL RIGHT

- Tilt

the cutting head

slightly LEFT then pull

the bevel release.

BEVEL ANGLE

POINTER

BEVEL ANGLE

POINTER

2b. Tilt the cutting head to the desired

bevel angle right as shown by the

bevel angle

pointer.

BEVEL ANGLE

POINTER

BEVEL ANGLE

POINTER