Last Update: 30/01/17

2

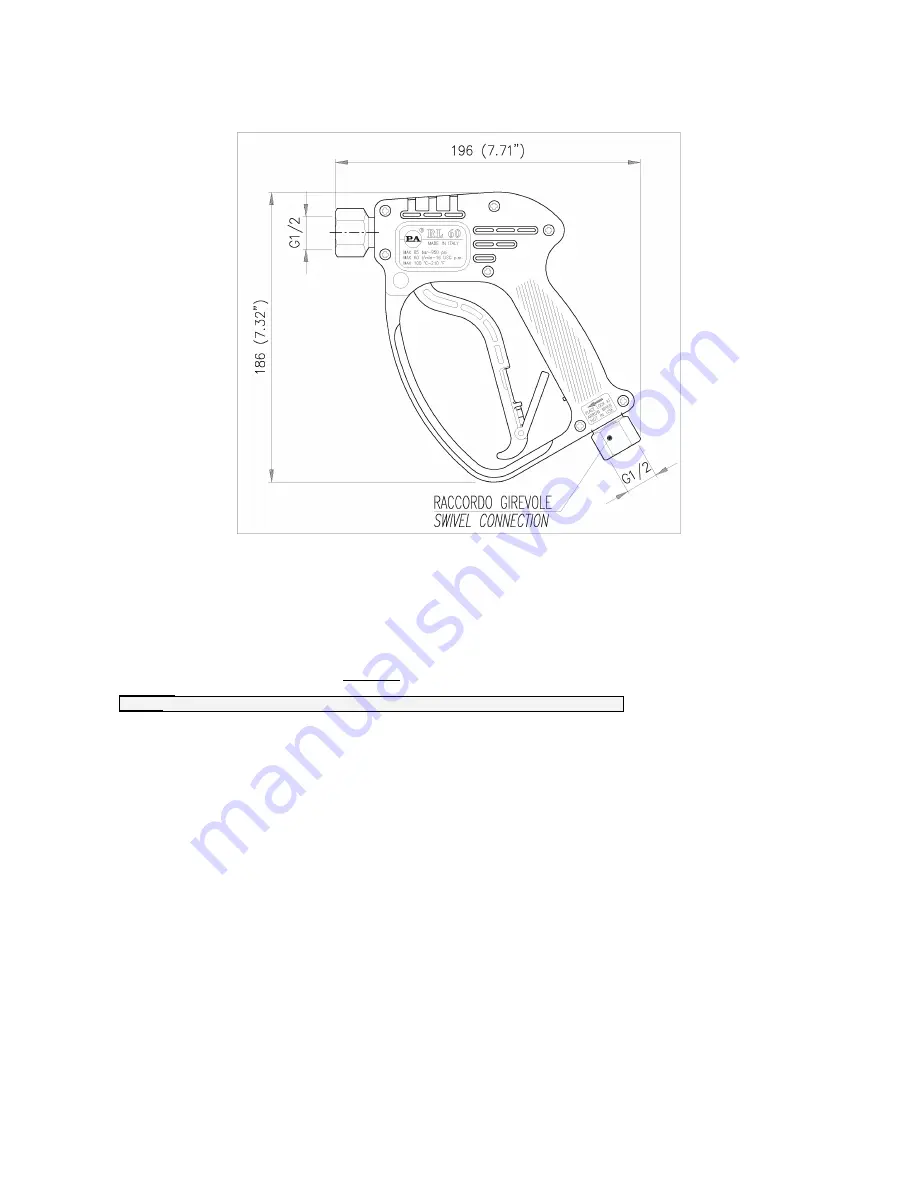

DIMENSIONAL DRAWING

INSTRUCTIONS

This product is to be utilized with clean fresh water, even slightly additivated with normal detergents. For use involving

different or corrosive liquids, contact the PA Technical department. Appropriate filtration should be installed when using

unclean liquids. Choose the gun in line with the data of nominal running (system rated pressure, max flow and max

temperature). In any case, the pressure of the machine should not exceed the permissible pressure rate imprinted on the

gun.

INSTALLATION

This gun was designed to operate with

hot water

(in compliance with the technical specs). Provide the plant generating

hot water

with an equipment limiting the incidental increase of the fluid temperature.

Always

fit a safety valve to protect the delivery conduct when the latter is under pressure.

Choose a suitable nozzle and ad just the valve mounted in the front of the gun, thus obtaining a constant supply and

avoiding unpleasant pressure spike when closing the system.

If the nozzle wears out, the pressure falls. When you install a new nozzle, adjust the system back to the original

pressure.

OPERATIONS

The gun opens and closes a high pressure conduct by means of a piston acting on a seat; the return is controlled by a

spring which releases the trigger

:

ATTENTION: this gun is equipped with a retarder closing device in order to limit

the pressure spikes on the pump and in particular conditions during the starting of the pump a pressure spout

may arise for a few seconds even with the gun closed. In order to prevent injuries or damage see illustrated

chart nr 10.9113.00 attached to the article.

WATER HOSE FEED

By high or very unsteady pressure values on delivery, it is necessary to mount a pressure reducer , both to level the flow

rate on delivery and to protect the system components.