Summary of Contents for PSB13-C4

Page 1: ...PSB13 C4 PSB13 D ...

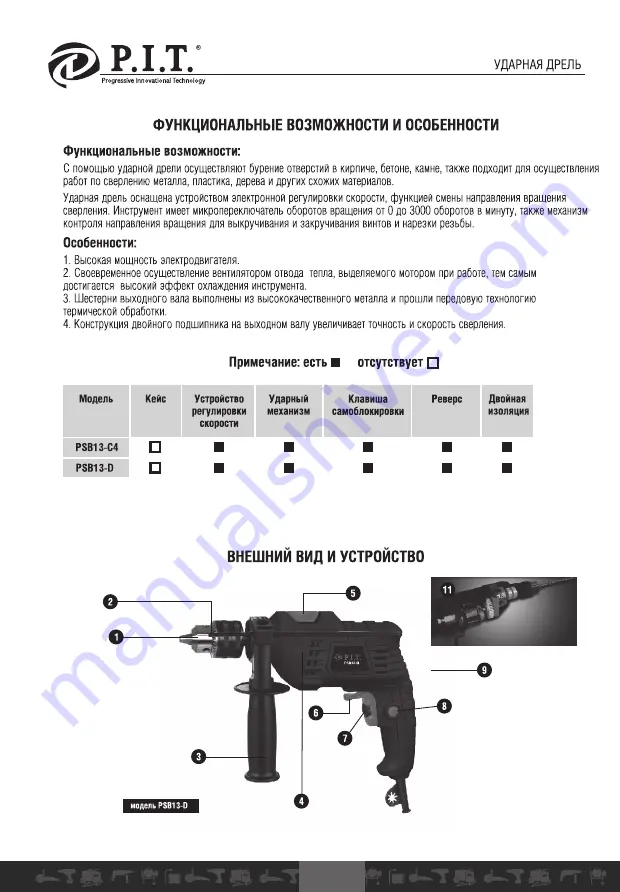

Page 5: ...4 impact drill ...

Page 6: ...5 impact drill ...

Page 10: ...9 impact drill ...

Page 11: ...10 ...

Page 12: ...11 ...

Page 13: ...12 ...

Page 14: ...13 ...

Page 15: ...14 ...

Page 16: ...15 ...

Page 17: ...16 ...

Page 18: ...17 ...

Page 19: ...18 ...

Page 20: ...19 ...

Page 21: ...20 ...

Page 22: ...21 P I T impact drill ...

Page 23: ...22 ...

Page 24: ...23 ...