18

MAN 9062965 EN V1

P. Lindberg A/S

Sdr. Ringvej 1

www.p-lindberg.dk

Tel.: +45 70212626

6600 Vejen, Denmark

E-mail: salg@p-lindberg.dk

Maintenance and lubrication

Maintenance schedule

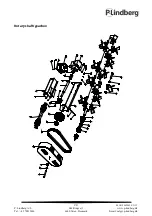

Replacing the pulley

Replace as required.

Replacing the flails

Replace as required.

Replacing the V-belt

Check the V-belt after a couple of hours of

operation and adjust its tension as required.

Replace as required.

Tightening of bolts

Check all of the bolts after a couple of hours

of operation and tighten if necessary.

Pay particular attention to the bolts on the

roller’s bearing housing and on the pulleys.

Gear oil

Check the oil level in the right-angle gear

unit and top up if necessary. See the

“Lubrication” section.

The gear oil must be changed at least every

two years.

Lubrication

Lubricate the machine, cf. the instructions in

the section about lubrication.

The long lifetime of all agricultural machinery depends on the correct servicing and

adjustment of the machines and their parts. Thorough and systematic inspection and

servicing can prevent the need for costly maintenance and repairs.

WARNING

For safety reasons, the PTO must be disconnected, the machine must

be lowered to the ground and the tractor switched off with the ignition

key removed before any maintenance work is carried out on the

machine.

•

After a maximum couple of hours of operation, check all of the bolts to ensure

they are secure and check the V-belt’s tension.

•

Replace worn, damaged or illegible safety labels. Contact the supplier to order

them.