13

MAN 9060917 EN V2

P. Lindberg A/S

Sdr. Ringvej 1

www.p-lindberg.dk

Tel.: +45 70212626

6600 Vejen, Denmark

E-mail: salg@p-lindberg.dk

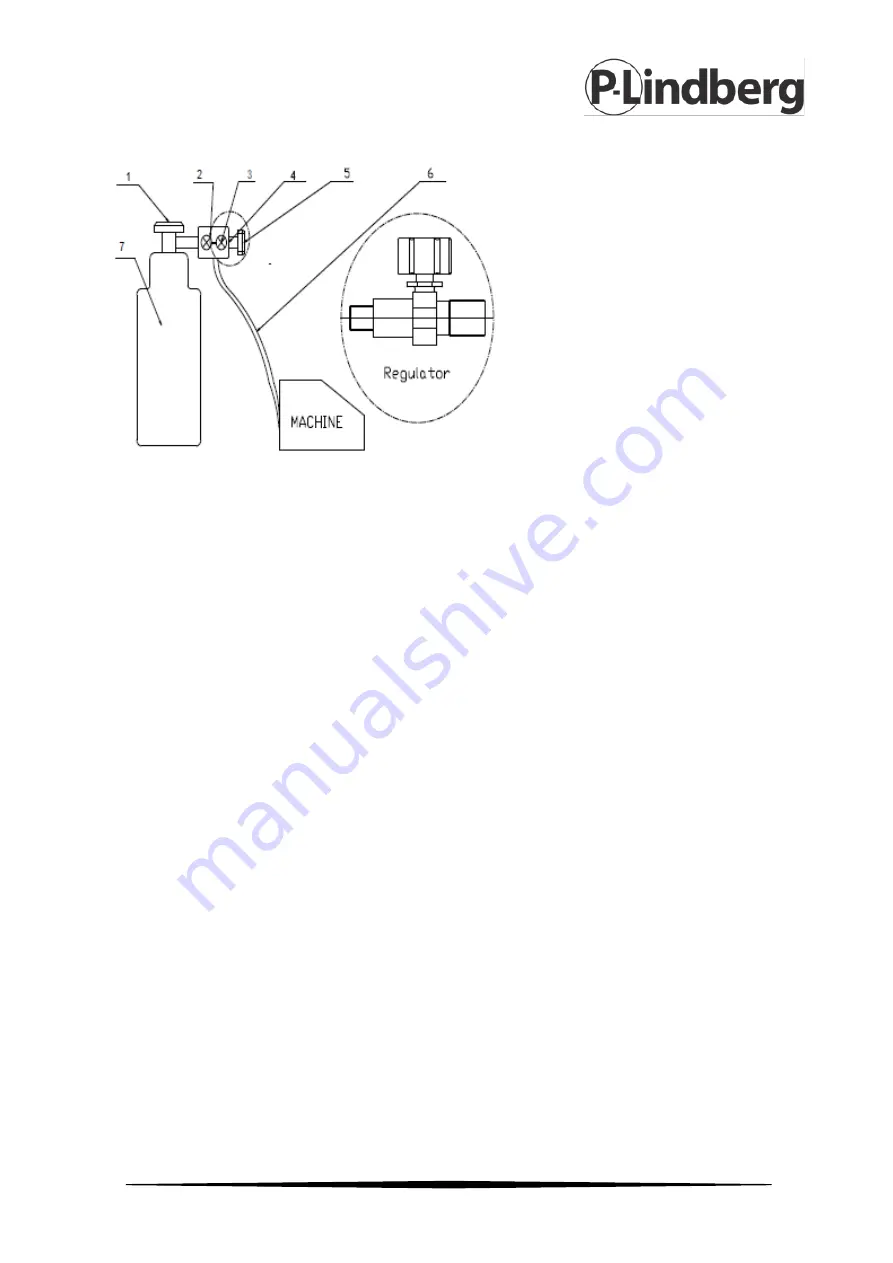

1)

Gas valve

2)

Pressure gauge

3)

Gas meter

4)

Regulator

5)

Knob for adjusting gas

pressure to the welder.

6)

Gas hose

7)

Gas cylinder

NB

Open the gas supply valve slowly by turning anticlockwise until the pressure is

registered on the first gauge on the regulator. Next, turn the supply adjust knob

slowly clockwise (to the right) to increase the gas flow to 20 cfm. To decrease the gas

flow, turn the supply adjust knob anticlockwise (to the left). The gas valve is positioned

on the rear panel and is activated using the trigger. You should hear the gas flow

when the trigger is activated. If there is no gas, it will result in a very hard arc that

splatters a lot and it will be difficult to achieve a smooth weld. Avoid wasting gas by

closing the valve when the work is done.

Different materials require different shielding gas when carrying out MIG welding.