16

MAN 9060917 EN V2

P. Lindberg A/S

Sdr. Ringvej 1

www.p-lindberg.dk

Tel.: +45 70212626

6600 Vejen, Denmark

E-mail: salg@p-lindberg.dk

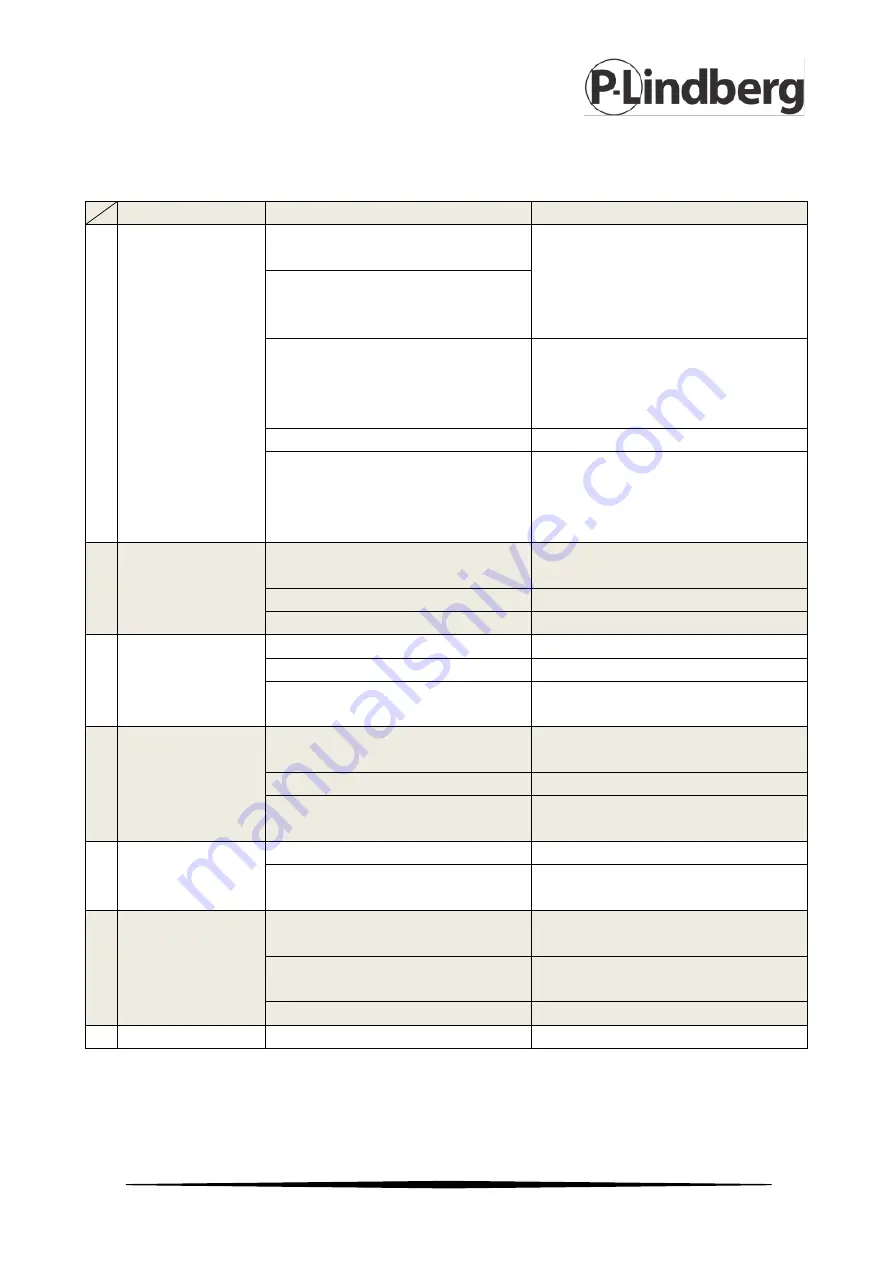

Troubleshooting

Fault

Possible cause

Solution

1

Yellow indicator

light is lit

Welding voltage is too high

(≥15%).

Switch off the power and check

the power supply. Restart the

welding apparatus when the

power has achieved normal

status.

Welding voltage is too low

(≤15%).

The ventilation does not work

and is leading to overheating

which is causing the

overheating protection to trip.

Check the fan and if required,

repair any faults.

Too high temperature.

Let the equipment cool down.

The equipment has been

continuously operating longer

than the recommended

continuous operating time.

Let the equipment cool down.

2

The wire feed

motor is not

working

properly.

The potentiometer is not set

correctly.

Rectify.

The nozzle is blocked.

Replace the nozzle.

The feed reel is loose.

Tighten the bolts.

3

The fan does not

work or revolves

very slowly.

The switch is broken.

Replace the switch.

The fan is broken.

Repair or replace the fan.

The cable is defective or has

fallen off.

Inspect the connection.

4

The welding arc

is unstable or

splatters a lot.

The power cable is too thin

making the power unstable.

Replace cable.

The voltage is too low.

Increase the voltage.

Too high resistance on the wire

feeder.

Clean or replace.

5

The welding arc

cannot be

controlled.

Poor earth connection.

Check and adjust.

The workpiece is dirty, greasy or

rusty.

Clean.

6

No shielding gas. The gun is not securely in

position.

Rectify.

The gas hose is compressed or

blocked.

Rectify.

The gas hose has a leak.

Rectify.

7

Other

-

Contact supplier.