INLINE MOUNT Exhaust Brakes

I N S T A L L A T I O N M A N U A L

- L 2 0 3 1

P G . 1 6

E N G I N E C O M P A R T M E N T

Connect the yellow wire from the cab to the remaining relay

wire using the splice connector supplied in the kit.

Secure all wiring and hoses away from heat sources and

moving parts.

T H R O T T L E S W I T C H I N S T A L L A T I O N

1 9 8 8 t o 1 9 9 3

Remove dash panel below steering column to access fuse

panel.

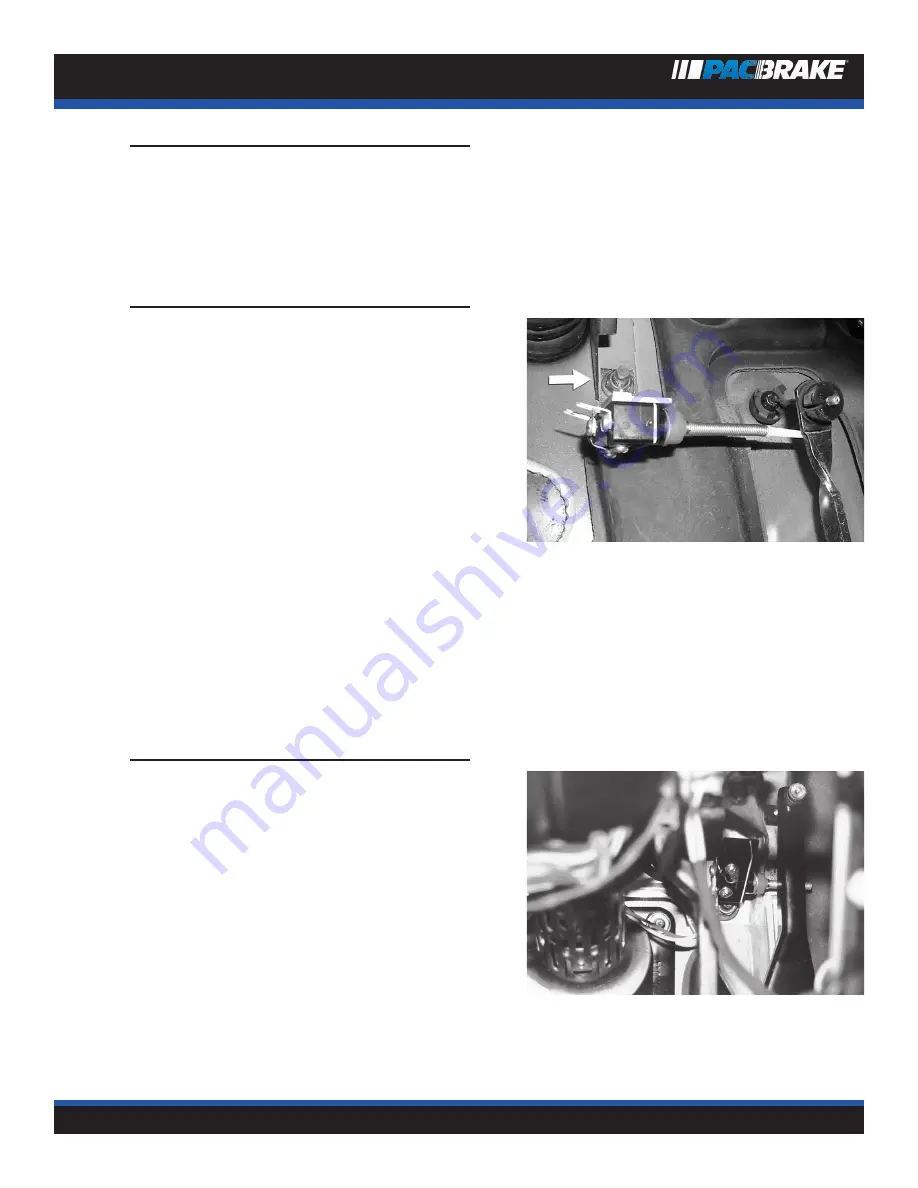

Locate stud shown in the photo and remove nut.

The header pipe kit contains an alternate throttle switch

bracket for pre-1994 vehicles.

Remove the switch from the bracket supplied in the main kit

and install on the alternate bracket.

Install the throttle switch assembly with the switch arm

horizontal. Reinstall the stud nut and tighten, making sure

the switch arm is behind the accelerator lever.

Adjust the switch by loosening the screws and positioning

it to “click” as the throttle returns to it’s released posi-

tion. Cycle the throttle and listen for the click each time the

throttle returns to idle. Tighten screws when adjustment is

complete.

Connect wires as shown in schematic page 16.

T H R O T T L E S W I T C H I N S T A L L A T I O N

( 1 9 9 4 A N D N E W E R )

Remove dash panel below steering column.

Locate the stud shown here and remove the nut.

Install the throttle switch assembly with the switch arm

horizontal.

Reinstall the stud nut and tighten, making sure the switch

arm is behind the throttle lever.

Adjust the switch by loosening the screws and positioning

it to “click” as the throttle returns to its released position.

Cycle the throttle and listen for the click sound each time

the throttle returns to idle.

Connect wires as shown in schematic page 16.

Summary of Contents for Inline Mount

Page 1: ......