Quarterly Inspection (every 3 months)

or monthly in

Severe Duty Applications or prior to placing the machine

in service if it has not been used for three months or

more. Documentation of the inspection records must be

kept with the hoist/crane for a minimum of two years from

date of the inspection.

1. Perform the Pre-use Inspection

2. Inspect all hoist fasteners for tightness and corrosion.

Replace all corroded fasteners and tighten per the

torque specifications on page 11.

Semi-annual Inspection (every 6 months)

, or quarterly

in Severe Duty Applications. Documentation of the

inspection records must be kept with the hoist/crane for a

minimum of two years from date of the inspection.

1. Perform the Pre-Use Inspection and Quarterly

Inspection.

2. Take a sample of the gear oil from the hoist drum fol-

lowing the oil sampling procedure on page 18. The oil

sample must be taken prior to changing the gear oil.

Analyze the sample for wear metals, viscosity, signs

of overheating, oxidation, water and other contami-

nants. If the oil sample contains an unusual amount of

metallic particles, the hoist should be removed from

service and undergo a tear-down inspection.

Annual Inspection, Testing & Preventive

Maintenance

or semi-annually in Severe Duty

Applications. Documentation of the inspections must be

kept with the hoist/crane fro a minimum of two years from

the date of inspection. The Annual inspection must

include but not be limited to the following:

1. Perform the Pre-Use Inspection, Quarterly and Semi-

annual Inspections.

2. Change the lubricating oil in the hoist drum after an oil

sample is taken. The gear oil must be changed to

remove wear particles that impede reliable and safe

operation of the brake clutch and erode bearings and

seals. Failure to change gear oil at recommended

intervals may contribute to intermittent brake slip-

page, loss of load control, injury or death. Refill the

hoist with recommended lubricant.

The gear oil should be changed whenever the ambi-

ent temperature changes significantly and an oil from

a different viscosity range would be more appropriate.

Oil viscosity is critical to reliable brake clutch opera-

tion. Our tests indicate that excessively heavy or thick

gear oil may contribute to intermittent brake clutch

slippage. Make certain the gear oil viscosity used in

your hoist is correct for your prevailing ambient tem-

perature. Failure to use the proper type and viscosity

gear oil may result in loss of load control, property

damage, injury or death.

NOTE: If the oil sampling/analysis has not been per-

formed as required, tear-down inspections will be

required. Refer to tear-down inspection procedures.

To change the gear oil, slowly rotate the drum until the oil

drain plug is aligned with the lower oil port access hole

(where equipped).

Caution

-

Do not place fingers into

drain access port

. Install a short length of pipe thread-

ed for 1 in. NPT into the threaded drain port in the cable

drum. Reach through the pipe with a long Allen key and

remove the drain plug. The oil will drain out the length of

pipe and not between the drum and base. When the oil

has drained, install the plug securely. Removing the vent

plug will hasten the oil drain.

3. The vent plug is typically located in the drum bearing

support. It is important to keep the vent plug clean and

unobstructed. Whenever the gear oil is changed, the

vent plug should be removed, cleaned in solvent and

reinstalled. Do not paint over the vent plug or replace

with a solid plug or grease fitting.

13

i

Summary of Contents for BRADEN BA3A

Page 2: ......

Page 25: ...23 THIS PAGE INTENTIONALLY LEFT BLANK...

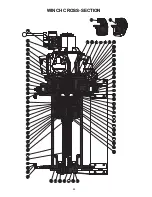

Page 26: ...24 WINCH CROSS SECTION...

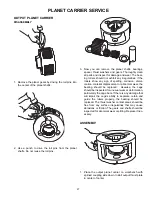

Page 35: ...33...

Page 37: ......