Proper oil sampling and analysis of the sample, is a

vital part of a comprehensive preventive maintenance

program. Information obtained from the oil analysis is

best utilized in conjunction with a regular program of

preventive maintenance. The early warning of abnor-

mal wear provided by an analysis program allows the

user to substitute preventive maintenance for a far

more costly and dangerous failure that may lead to loss

of load control that could result in property damage,

personal injury or death. Early detection of accelerat-

ed component wear allows the scheduling of corrective

maintenance and can reduce in-operation failures and

costly down time.

Taking A Valid Oil Sample

Prepare the hoist by cleaning the drain area and drain

extension tube in order to obtain an uncontaminated

sample. Operate the hoist in both directions for one to

two minutes and then take the oil sample from the drain

port as soon as possible. Do not take the sample from

the first oil out the drain port. Take a sample from the

mid-stream flow of the oil to obtain an accurate repre-

sentation of the oil condition. After taking an oil sam-

ple, check the oil level and add new oil as required.

Refer to the applicable Braden service manual for rec-

ommended lubricant.

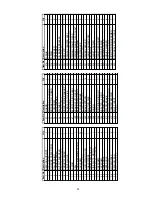

Analysis

General Guidelines

(After approximately 250 hours of operation)

Iron Contaminates

100 to 500 ppm

Normal

501 to 800 ppm

Caution - Abnormal Sample (mon-

itor more frequently), tear-down

inspection may be required.

801 ppm & up

Unacceptable - Abnormal Sample

(tear-down inspection required.

In all contaminate monitoring, equally important as the

level of contamination, is the change in the amount of

contamination compared to previous samples.

OIL SAMPLING AND ANALYSIS

Hot oil may cause personal injury and/or burns to

unprotected skin. Make certain the oil has cooled to

a safe temperature (less than 110°F or 43°C) before

taking an oil sample, changing oil or servicing the

hoist.

17

Summary of Contents for BRADEN BA3A

Page 2: ......

Page 25: ...23 THIS PAGE INTENTIONALLY LEFT BLANK...

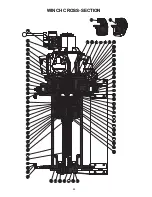

Page 26: ...24 WINCH CROSS SECTION...

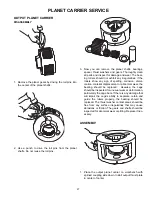

Page 35: ...33...

Page 37: ......