28

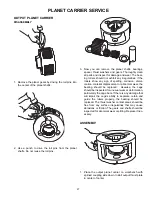

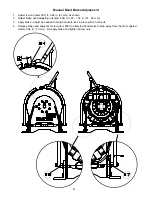

2. Insert two (2) bearings and a bearing spacer into a

gear with the spacer between the bearings. Place a

thrust washer on each side of the gear and position in

a carrier opening. Slide the shaft through the carrier,

thrust washer, bearing-gear sub-assembly and

remaining thrust washer.

3. Carefully align the pin hole in the carrier with the hole

in the planet gear shaft and drive the roll pin into

place. Always use NEW roll pins. When properly posi-

tioned, 50% of the roll pin will engage the planet gear

shaft and 50% will remain in the planet carrier.

4. Note that the roll pin is slightly recessed in the carrier

when properly installed. With a center punch, stake

the carrier next to the pin hole as shown. This will dis-

tort the hole so the pin will not back out. Repeat these

steps for each of the three planet gears.

PRIMARY PLANET CARRIER

1. To service the primary planet carrier, the steps are the

same as for the output carrier except there is only one

bearing for each gear and no bearing spacer.

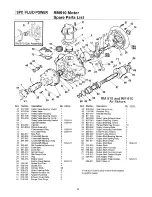

Summary of Contents for BRADEN BA3A

Page 2: ......

Page 25: ...23 THIS PAGE INTENTIONALLY LEFT BLANK...

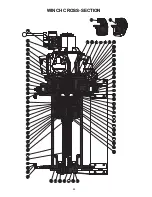

Page 26: ...24 WINCH CROSS SECTION...

Page 35: ...33...

Page 37: ......