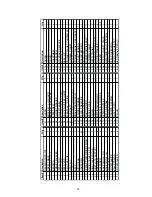

11

Dry

Lubed

Dry

Lubed

Dry

Lubed

Dry

Lubed

Torque (LB-FT)

Grade 5

Grade 8

1/4

20

28

5/16

3/8

18

24

16

24

7/16

1/2

9/16

5/8

8

6

12

9

17

13

24

18

45

35

70

50

23

31

50

35

80

110

80

150

110

110

55

75

150

115

210

160

14

20

13

20

12

18

11

18

265

200

Torque (LB-FT)

Grade 5

Grade 8

380

280

7/8

9

14

420

325

600

450

3/4

10

16

680

1 1/8

7

12

790

590

1290

970

1

8

14

640

7

12

1120

835

910

485

1460

1820

1360

1 3/8

6

12

1460

1095

2385

1790

1 1/4

3160

2370

RECOMMENDED FASTENER TORQUE

Bolt Dia.

Inches

Thds Per

Inch

Bolt Dia.

Inches

Thds Per

Inch

1 1/2

6

12

1940

3. Ensure the preventative maintenance requirements,

on pages 12 and 13 of this manual have been met.

Inspect the wire rope and winch and repair any

defects before operating the winch.

4. Ensure operators are trained and understand the

General Safety Recommendations section of this

manual.

5. After the hoist/boom is properly positioned, we rec-

ommend the operator slowly pay-out, then haul-in a

short length of cable. The winch should perform

these operations in a smooth and controlled manner.

If the hoist does not operate smoothly or makes any

unusual sounds, the source of the problem should be

identified and corrected before any attempt is made to

lift the load.

6. When lifting loads, we recommend the following

steps:

•

Slowly pay-out wire rope from the hoist drum

until it reaches the load.

•

Securely fasten the hoist cable to the load and

be sure all ground personnel are a safe distance

from the load.

•

Slowly lift the load a short distance and stop. A

small amount of "bounce" may be observed,

depending on the weight of the load, size and

type of wire rope, and the amount of boom ex-

tension.

•

Allow the load to stabilize then watch for any

signs of downward movement of load or any

cable drum rotation. The winch static brake

should hold the load in place without allowing

any downward movement.

•

If the load creeps down or there is any move-

ment of the cable drum, the load should be low-

ered to the ground immediately and the source of

the problem identified and corrected.

•

If the winch is holding the load securely, proceed

with normal operations in accordance with the

equipment manufacturer's operating procedures.

7. The air motor should not be allowed to race when

lowering heavy loads. Always operate within the

speeds given in the sales brochure.

Summary of Contents for BRADEN BA5A

Page 2: ......

Page 25: ...23 THIS PAGE INTENTIONALLY LEFT BLANK...

Page 26: ...24 WINCH CROSS SECTION...