26

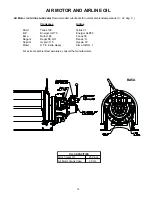

WINCH ASSEMBLY

Replace the seals in winch drum and closure and replace

all o-rings

.

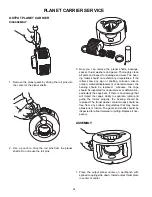

The procedure below assumes the planet carrier and

overrunning clutch subassemblies are built. Refer to

planet carrier and overrunning clutch subassembly

instructions if needed

.

1. Prepare for installing bearing support (1) into support

end side plate (20) by placing side plate on a work

table and using wood blocks to make clearance for

the bearing support. Lower bearing support into side

plate with the vent at the 12 O’clock position. Install

bolts (22) and lockwashers (30). Torque bolts to 110

± 5 ft-lbs. The bolts can be torqued after the sideplate

is bolted to the base angles if more leverage is need-

ed

.

2. Place base angles on the ground aligned for assem-

bly. The 5/8 tapped holes for the band brake hard-

ware are on the motor end support. Install support

end side plate (20) in the base angles. The guard

bracket will attach at the upper inboard bolt on both

base angles

.

3. Stand support end sideplate and base angles assem-

bly on end with support end side plate down. A 2 x 4

should be placed under the side plate just above the

bearing support to level the assembly

.

4. Install drain plug in the winch drum. Apply general

purpose grease to the bearing support seal and bear-

ing surfaces, and ensure the seal and bearing are

installed in cable drum. Lift the cable drum and lower

slowly onto the bearing support using the clamps

shown (Wes has drawing) taking care not to damage

the seal

.

5. Install the output planet carrier assembly (400) onto

the bearing support shaft. Ensure the carrier splines

engage on the output shaft. Install the output carrier

thrust washer (5), and output sun gear (6)

.

6. Install the ring gear (13). Install the second planet

carrier assembly ensuring the thrust washer (5)

remains in position and the splines engage with the

output sun gear splines

.

7. Install second sun gear (8) and thrust washer (5)

.

8. Install the primary planet carrier assembly again

ensuring the thrust washer (5) remains in position and

the carrier splines engage with the second sun gear

.

9. Install the thrust washer (34) into the primary planet

carrier and install the primary sun gear (7)

.

10. Apply general purpose grease to the drum closure o-

ring (11) and install the drum closure into the winch

drum.

11. Bolt the motor end side plate to base angles. The

guard bracket will attach at the upper inboard bolt on

the base angle.

12. Apply general purpose grease to the bearing and seal

surfaces on the brake cylinder and drum closure.

Slowly lower the brake cylinder into the side plate tak-

ing care not to damage the drum closure seal, and

position with the brake release fitting at the 6 o’clock

position. Apply Loctite 242 to the capscrews (219)

and torque to 110 ± 5 ft•lbs

.

13. Place the spring spacer (210) and twelve brake

springs (203) in the brake cylinder. Place the pres-

sure plate (202) on top of the brake springs

.

14. Install the brake discs on the pressure plate. The

brake plate (204) is first followed by a friction disc

(205) and alternating. There will be four brake plates

and three friction discs

.

15. Install the three brake release pins (221) in the brake

cylinder aligning them with the notches in the brake

plates

.

16. Before installing the sprag clutch, check position for

installation: While holding the outer race, the inner

race should turn freely in the clockwise direction

.

17. Ensure sprag clutch inner race retaining ring is prop-

erly seated and install the sprag clutch aligning inner-

race splines with the sun gear (7) and outer race

splines with the friction plates. Ensure the inner-race

retaining ring is seated against the sun gear (7). After

installing, correct installation should be checked by

turning the inner race in the clockwise direction –

ensure the outer race is not turning

- and observ-

ing the drum turning in the counter-clockwise (hoist)

direction. If the drum turns in the clockwise (lowering)

direction, remove the sprag clutch. Turn the sprag

clutch 180º reinstall and recheck

.

18. Apply general purpose grease to the o-rings on the

brake piston (202). Set the brake piston on the brake

cylinder and tap evenly around the circumference with

a rubber mallet to install

.

19. Set the motor adapter on the brake cylinder and align

bolt holes. Ensure the motor bolt holes are aligned so

the control valve will be at the 12 o’clock position

when the motor is mounted. Apply Loctite 242 to cap-

screws and tighten evenly one turn each in a cross

pattern until the motor adapter is seated. Torque the

capscrews to 110 ± 5 ft-lb

.

Summary of Contents for BRADEN BA5A

Page 2: ......

Page 25: ...23 THIS PAGE INTENTIONALLY LEFT BLANK...

Page 26: ...24 WINCH CROSS SECTION...