1. Remove the wire rope from the cable drum and

rotate the drum until the fill/drain plug is at the bot-

tom, six o'clock position. Remove the drain plug and

capture the gear oil in a suitable container. Recycle

or dispose of used oil in an environmentally respon-

sible manner. Install the drain plug.

2. Label the hydraulic hoses as they are removed from

the hoist motor. Install plugs in the open hoses and

motor ports to reduce entrainment of dirt in the open

port.

3. Remove the hoist mounting fasteners and lift the

hoist from the mount. Begin disassembly by placing

the hoist on a stable work surface with the motor

end facing up. Secure the hoist in this position to

prevent it from falling and causing injury.

4. Remove the hose that connects the brake valve to

the brake release port. Remove the fasteners secur-

ing the motor to the brake cylinder assembly. Lift the

motor straight up to disengage the motor shaft from

the brake clutch assembly.

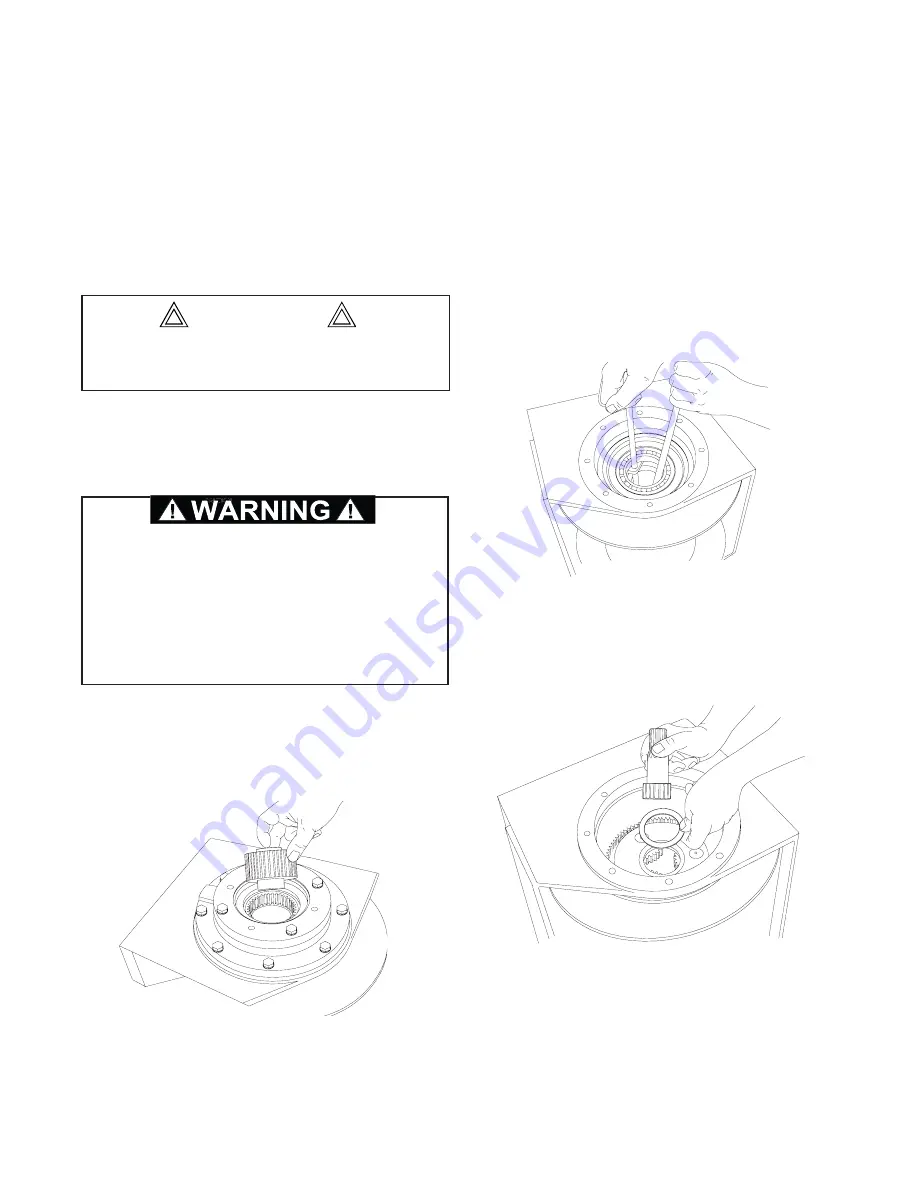

5. Remove the brake clutch assembly from the brake

cylinder assembly. Refer to "Brake Clutch Service"

section for additional information.

6. Place an alignment mark on the brake cylinder and

the hoist end-bracket to ensure the correct position

of the brake cylinder on the end-bracket is main-

tained. Remove the eight capscrews that secure the

brake cylinder to the hoist end-bracket. Install two

½-13 in. eye-bolts into the motor mounting holes

and lift the brake cylinder out of the hoist end-brack-

et. Be careful to avoid damaging the seal surfaces

of the brake cylinder. Refer to "Brake Cylinder

Service" for additional information.

7. Remove the capscrews that secure the two tie-

plates to the hoist end-brackets and remove the tie-

plates and the motor end end-bracket.

8. Install two 3/8-16 in. eye-bolts into the drum closure

or use two heel-type pry bars placed between the

primary planet carrier and the drum closure, pry

upward to remove the drum closure. Remove the

seal and bearing from the drum closure as required.

9. Remove the primary sun gear and thrust washer

from the primary planet carrier. Remove the primary

planet carrier from the drum. The planet shafts are

tapped for ¼-20 in. lifting bolts for convenience.

Lifting hooks may also be fabricated from steel bar.

Refer to "Planet Carrier Service" for additional infor-

mation.

DISASSEMBLY OF WINCH

15

The H20R hoist weighs approximately 500 pounds

(227 kg). Use adequate lifting equipment.

CAUTION

All disassembly and assembly MUST be performed

with the motor end facing up. The thrust washer

located under the input sun gear may become dis-

lodged if components are removed while the hoist is

in the horizontal position. The dislodged thrust wash-

er may become trapped in the hoist gear train and

cause a catastrophic failure that may result in loss of

load control, property damage injury or death.