This is a convenient time to add the five pints (2.4 liters)

of recommended gear oil to the winch gear cavity. Refer

to the "Recommended Lubricant" chart for more infor-

mation.

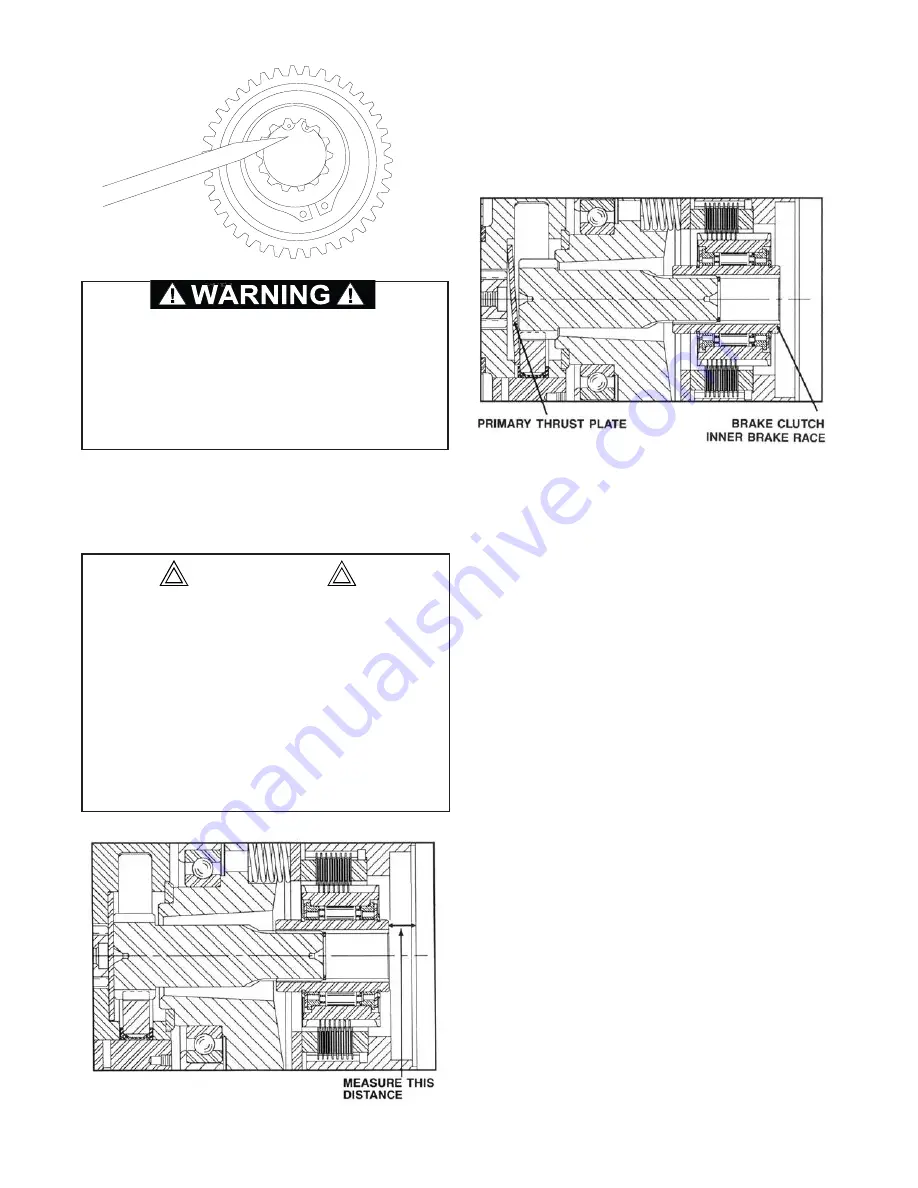

Measure the distance from the motor mounting surface

to the inner brake race. With all components properly

installed, this distance should be 11/16 in. (17.5 mm) to

3/4 in. (19.1 mm). If this distance is less than 9/16 in.

(14.3 mm), the primary spacer may be positioned as

shown below and should be checked.

The primary thrust plate is shown wedged between the

planet gears and the planet carrier. Note that the pri-

mary sun gear and the entire brake clutch assembly

have moved to the right (toward the hydraulic motor).

11. Install a new o-ring onto the motor pilot. Lubricate

the pilot o-ring and install the motor onto the motor

adapter. Evenly tighten the capscrews to 110 lb.-ft.

(149 N-m) torque.

12. Install the hoses that connect the brake valve and

motor to the brake cylinder. After the winch assem-

bly is complete, check all fasteners and fittings for

proper torque.

Care must be taken to assure the primary thrust

plate remains properly located in its counterbore

when the motor is installed for the first time, or is

being reinstalled on the winch. It is possible for the

primary thrust plate to drop out of its counterbore and

become wedged between the planet gears and the

planet carrier. If the winch is operated with the pri-

mary thrust plate wedged between primary gears

and the planet carrier, or with a thrust washer out of

position, severe damage to internal winch compo-

nents could result.

CAUTION

25

Be certain the snap ring is seated in the groove in

the splined bore of the inner race. This snap ring will

keep the brake clutch assembly correctly positioned

in the center of the friction brake pack. Binding of the

brake or brake failure may occur if this snap ring is

omitted. Brake failure may result in loss of load con-

trol, property damage, injury or death.