DESCRIPTION OF WINCH

The winch has four basic component parts:

1. Winch base

2. Hydraulic motor and brake valve

3. Brake cylinder and motor support

4. Drum assembly

The drum assembly consists of three basic assemblies:

1. Drum with integral ring gear

2. Output planetary gear set

3. Primary planetary gear set

The hydraulic motor is bolted to the motor support

which in turn is bolted to the brake cylinder and the

base. The motor end of the drum, running on a ball

bearing, is supported by the brake cylinder. The other

end of the drum runs on a ball bearing on the support

bolted to the base. The ring gear for both planetary sets

is machined into the drum’s inside surface.

WINCH OPERATION

The hydraulic motor drives the sun gear of the primary

planetary gear set through the splined inner race of the

brake clutch. When driven by the sun gear, the primary

planet gears walk around the ring gear in the drum and

drive the primary planet carrier.

The primary planet carrier drives the output planet sun

gear which, in turn drives the output planet gears. The

output planet carrier is splined to the bearing support

and cannot rotate. Therefore, as the output planet gears

are driven by the sun gear, they will drive the ring

gear/drum.

D

UAL

B

RAKE

S

YSTEM

– D

ESCRIPTION

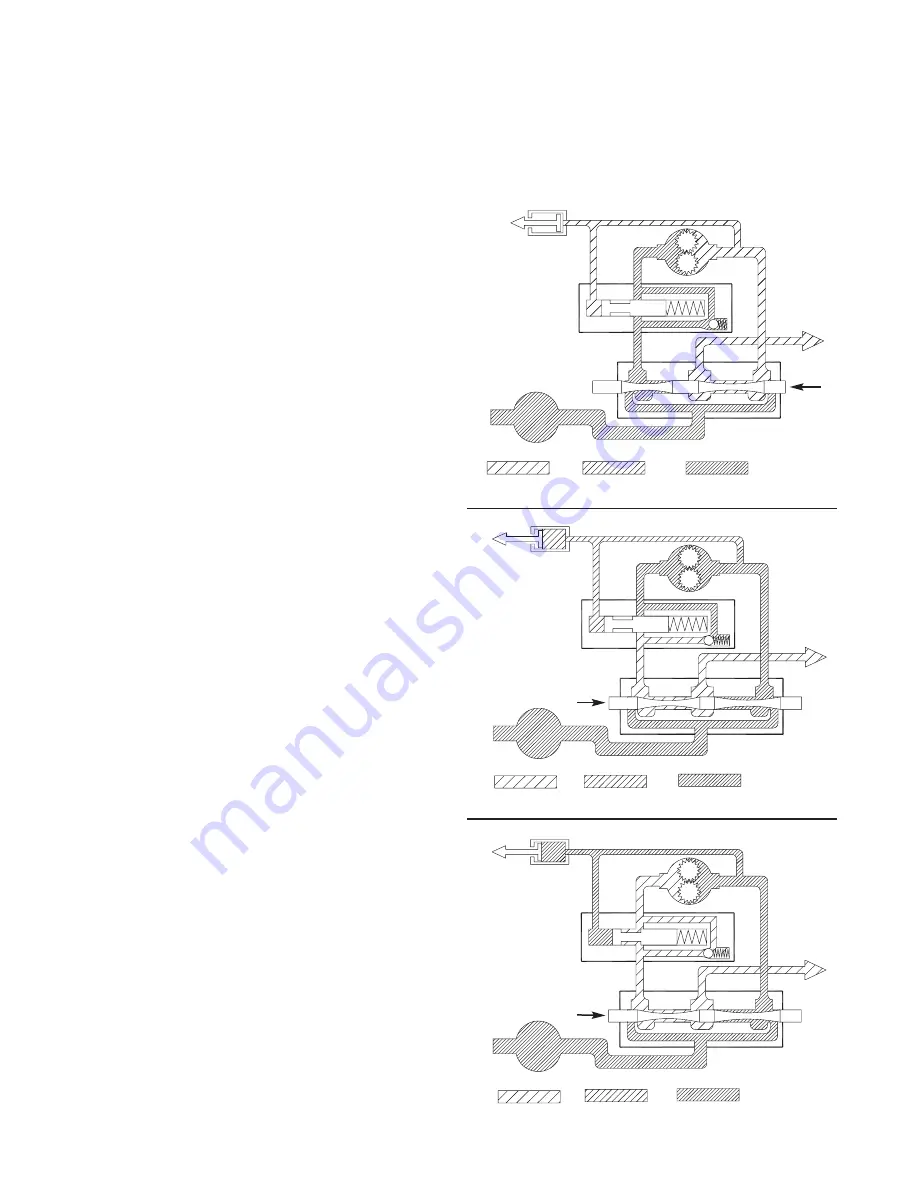

The dual brake system consists of a dynamic brake sys-

tem and a static brake system.

The dynamic brake system has two operating compo-

nents:

1. Brake valve assembly

2. Hydraulic motor

The brake valve is basically a counterbalance valve. It

contains a check valve to allow free flow of oil to the

motor in the hoisting direction and a pilot operated,

spring-loaded spool valve that blocks the flow of oil out

of the motor when the control valve is placed in neutral.

When the control valve is placed in the lowering posi-

tion, the spool valve remains closed until sufficient pilot

pressure is applied to the end of the spool to shift it

against spring pressure and open a passage. After the

spool valve cracks open, the pilot pressure becomes

flow-dependent and modulates the spool valve opening

which controls the lowering speed.

Figures 2, 3 & 4 show a simplified version of the brake

valve for illustrative purposes.

The static brake system has three operating compo-

nents:

1. Spring Applied, Multiple Friction Disc Static Brake

2. Brake Clutch Assembly

3. Hydraulic Piston and Cylinder

4

THEORY OF OPERATION

Pump

Brake

Valve

Static

Brake

Motor

Control

Valve

Low Pressure Medium Pressure High Pressure

To

Tank

Figure 3

Pump

Brake

Valve

Static

Brake

Motor

Control

Valve

Low Pressure Medium Pressure

High Pressure

To

Tank

Figure 2

Pump

Brake

Valve

Static

Brake

Motor

Control

Valve

Low Pressure Medium Pressure High Pressure

To

Tank

Figure 4