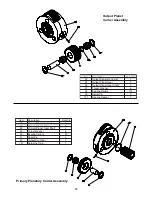

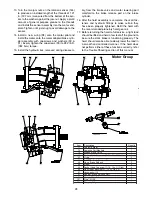

Disassembly

1. With a pin-punch, drive the spirol pins into the plan-

et gear shafts until the spirol pins clear the planetary

carrier. Slide the planet gear shafts out of the carrier

far enough to allow access to the drive the spirol

pins out of the shafts.

2. Finish removing the planet shafts, gears, bearing

rollers and thrust washers from the planet carrier.

Thoroughly clean all parts and inspect for damage

and wear.

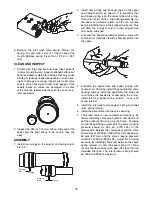

• The bearing rollers should not exhibit any irregu-

larities. If the rollers show any sign of pitting, cor-

rosion or discoloration the rollers must be

replaced. If replacing one roller, then ALL the

rollers must be replaced.

• The gear teeth wear surface must be smooth and

free of any pitting or uneven wear. The bearing

roller contact surfaces inside the gear must be

smooth and free of pitting, scoring or discol-

oration. If the gear shows any abnormal signs, the

gear must be replaced.

• The planet gear shafts must be smooth and free

of any pitting, uneven wear or discoloration. If the

shafts show any abnormal signs, the shaft must

be replaced.

Assembly

1. Place the planetary carrier on a clean work surface

with the splined collar facing up.

2. Apply a liberal coat of oil–soluble grease, such as

Lubriplate 105, to a thrust washer and center the

washer on one side of a planet gear. Place the plan-

et gear on a clean surface with the thrust washer

down. Apply a liberal coat of oil-soluble grease in the

bore of the gear then stack a row of bearing rollers

into the planet gear, using the grease to hold the

rollers in position. There are 19 rollers in each pri-

mary planet gear and two rows of 19 rollers separat-

ed by a spacer ring in the output planet gears. Place

a second thrust washer on top of the planet gear.

Carefully slide the planet gear with, bearing rollers

and thrust washers into the carrier. Install the planet

gear shaft taking care to align the roll-pin hole with

the roll-pin hole in the carrier.

3. Install NEW spirol pins into the carrier and planet

gear shafts. Drive the spirol pin, far enough into the

planetary carrier to equally engage the shaft and the

planet carrier. The outer end of the spirol pin should

be recessed approximately 1/32 in. (1 mm) in the pri-

mary planetary carrier and recessed approximately

1/16 in. (2 mm) in the output planetary carrier. With

a center punch, deform (stake) the outer edge of the

planetary carrier next to the spirol pin to prevent the

pin from backing out.

4. Repeat this assembly procedure for the remaining

planet gears.

PLANETARY CARRIER SERVICE

Do not reuse spirol pins. Their resistance to move-

ment is reduced with reuse. Reusing spirol pins may

result in a pin moving out of the planet gear shaft and

carrier which may lead to misaligned gears, foreign

object damage to the gear train and catastrophic

gear train failure. Gear train failure may result in loss

of load control, property damage, injury or death.

The planet gear shafts will pass easily through the

planet gear bearing rollers and thrust washers with

only a slight amount of drag. If there is any binding,

STOP and realign the rollers and thrust washers. DO

NOT drive the planet gear shafts into the carrier with

a hammer as damage to the thrust washers and

bearing rollers may result. Damaged gear train com-

ponents may cause a catastrophic gear train failure

that may lead to loss of load control, property dam-

age, injury or death.

(See the following page for illustrations)

21