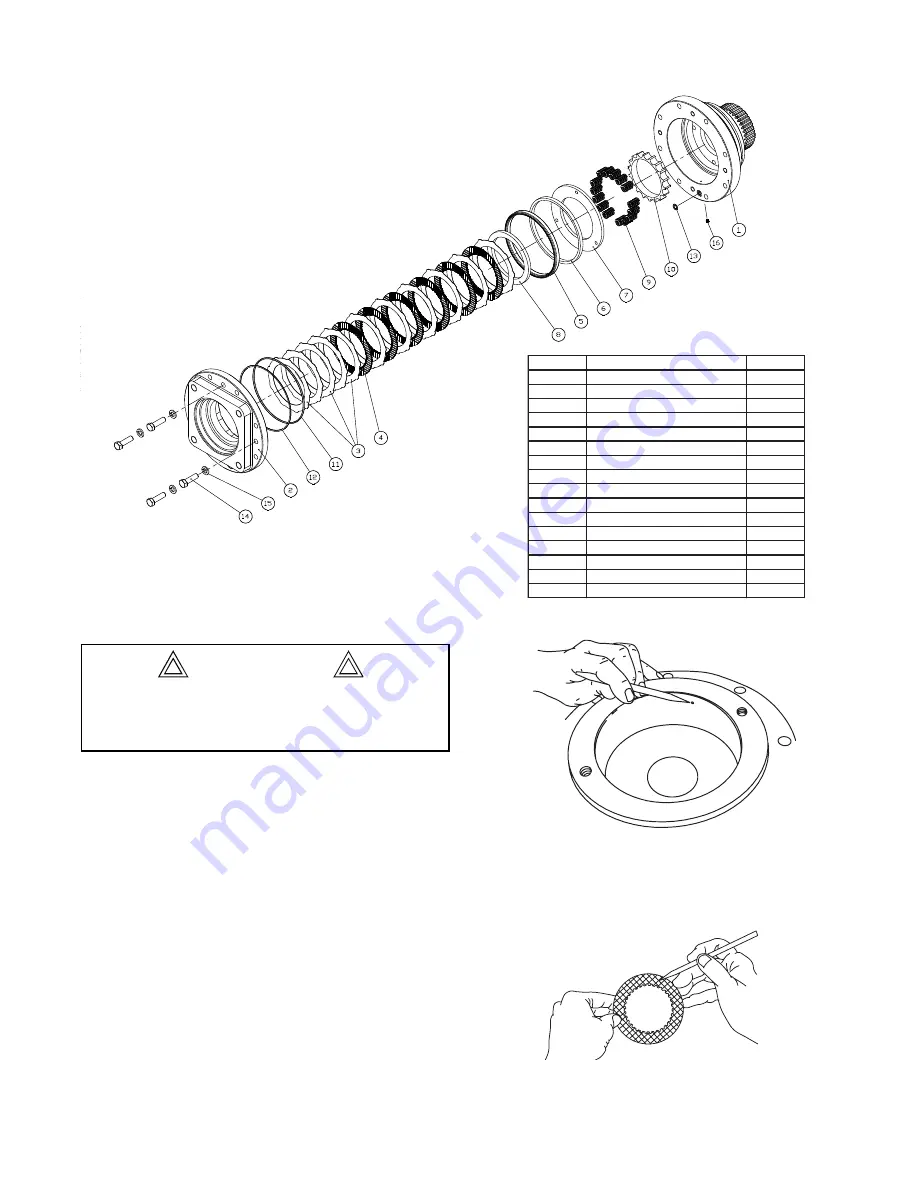

Disassembly

The brake cylinder assembly is secured to the hoist

end-plate by eight

½

-13 X 3 capscrews. The remaining

four

½

- 13 X1

¾

capscrews (14) located at 3, 6, 9, and

12 o’clock positions, hold the motor adapter (2) to the

cylinder (1) and compress the brake springs (9).

1. Place the brake cylinder assembly on a clean work

surface with the splined end down. Evenly remove

the four capscrews (14) and washers (15). Use a

cross pattern when loosening the capscrews one

turn at a time until the spring tension is released.

2. Remove the motor adapter (2) and lift out the brake

discs (3 & 4) and the spacer (8).

3. Remove the o-ring and back-up ring (11,12) from the

motor adapter. Remove the seal (5) from the cylin-

der (1). Remove the steel piston back-up ring (6)

from the cylinder.

4. Remove the pressure plate (7) and the springs (9)

and spring spacer (10).

Clean and Inspect

1. Thoroughly clean all the brake cylinder parts at this

time. Check sealing surfaces on both the cylinder

and the motor adapter. Be sure the brake release

port is clean.

2. Place the friction discs (4) on a flat surface and

check for distortion with a straight edge. The friction

BRAKE CYLINDER SERVICE

The motor adapter is under spring tension from the

brake springs. Loosen each of the capscrews one

turn at a time until spring tension is released.

Item

Description

Quantitiy

1

Brake Cylinder Housing

1

2

Motor Adapter

1

3

Steel Separator Discs

11

4

Friction Discs

6

5

Piston Seal

1

6

Piston Back-up Ring

1

7

Pressure Plate

1

8

Brake Plate Spacer

1

9

Brake Spring

15

10

Spring Spacer

1

11

O'ring

1

12

Back-up Ring

1

13

O'ring

1

14

Capscrew

4

15

Lockwasher

4

16

Expansion Plug

1

24

CAUTION