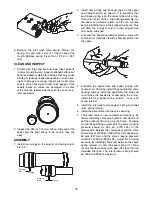

material must appear even across the entire surface

with a groove pattern visible. Replace the friction

discs if the splines are worn to a point, the disc is

warped, burned or worn unevenly. The minimum

groove depth is .003 in. (.08 mm).

3. Place the steel separator discs (3) on a flat surface

and check for distortion with a straight edge.

4. Inspect the surfaces for signs of material transfer or

excessive heat. Replace the disc if distorted, heat

discolored or mechanically damaged.

5. Measure the brake spring free length. The minimum

free-length is 1 7/16 in. (36.5 mm). Inspect the

springs for any signs of cracking or fatigue. If a

spring must be replaced for any reason, then ALL

the springs must be replaced to ensure even brake

application force.

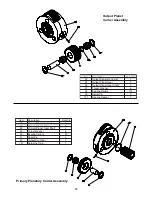

Assembly

1. Place the motor adapter (2) on a clean work surface

with the motor side facing down. Apply a light coat of

hoist gear oil to the new brake piston seal (5) and

install the seal onto the adapter with the sealing lip

edge toward the motor. Install the o-ring and back-up

ring (11, 12) onto the motor adapter with the back-up

ring toward the motor. The cupped surface of the

back-up ring (12) must face toward the o-ring.

2. Install a steel brake separator disc (3) into the motor

adapter followed by a friction disc (4). Continue to

alternately install steel and friction discs until there

are 11 steel and 6 friction discs. Finish with 5 steel

discs on top.

3. Install the brake plate spacer ring (8) on top of the

last steel brake disc.

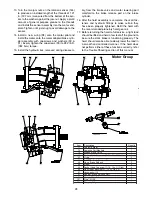

4. To check brake stack height, place pressure plate

(7) on top of brake spacer. Hold pressure plate

down firmly by hand and measure gap (in three

places) between motor adapter and pressure plate.

Average gap must measure between 0.160 in. (4

mm) maximum and 0.080 in. (2.0 mm) minimum. If

the gap exceeds the maximum limit, there may be

too many discs in the stack-up or the discs are dis-

torted. If the gap is less than the minimum, there

may be too few discs or the discs are worn beyond

their serviceable limit and should be replaced.

When the gap is within the minimum and maximum

values, remove the pressure plate and all brake

discs. Lubricate all friction discs with the same oil to

be used in the hoist. Install all brake discs and brake

plate spacer as described in steps 2 and 3.

5. Place the brake cylinder on a clean work surface

with the splined end down. Install the spring spacer

(10), then the 15 springs (9).

6. Install the pressure plate (7) into the brake cylinder.

Be careful that none of the springs fall over. Install

the steel backup ring (6). Apply petroleum jelly or an

oil soluble grease to a new O-Ring (13) and install it

in the brake cylinder.

Failure to replace brake springs as a set may result

in uneven brake application pressure and repeated

brake spring failure.

CAUTION

Measure gap between

pressure plate and

motor adapter

Always use the molded spring spacer to properly

position the springs in the brake cylinder. Failure to

install the spring spacer may allow the springs to

contact each other and become damaged. This

could result in loss of load control, property damage,

injury or death.

25