13. Turn the two jam nuts on the rotation sensor (144)

to produce an installed length of the threads of 1.21

in. (30.7 mm) measured from the bottom of the sen-

sor to the washer against the jam-nut. Apply a small

amount of general purpose grease to the threads

and install the sensor assembly into the motor end-

plate. Tighten until just snug to avoid damage to the

sensor.

14. Install a new o-ring (98) onto the motor pilot and

install the motor onto the motor adapter/brake cylin-

der assembly with capscrews and washers (90 &

91). Evenly tighten the capscrews (90) to 282 lb.-ft.

(382 N-m) torque.

15. Install the hydraulic lies, removed during disassem-

bly, from the brake valve and motor lowering port

manifold to the brake release port on the brake

cylinder.

16. After the hoist assembly is complete, check all fas-

teners and hydraulic fittings to make certain they

have been properly tightened. Refill the hoist with

the recommended planetary hoist gear oil.

17. Before returning the hoist to full service, a light load

should be lifted and held a few feet off the ground to

be sure the static brake is functioning properly. The

hoist should also be able to slowly lower the load in

a smooth and controlled manner. If the hoist does

not perform either of these functions correctly, refer

to the Trouble Shooting section of this manual.

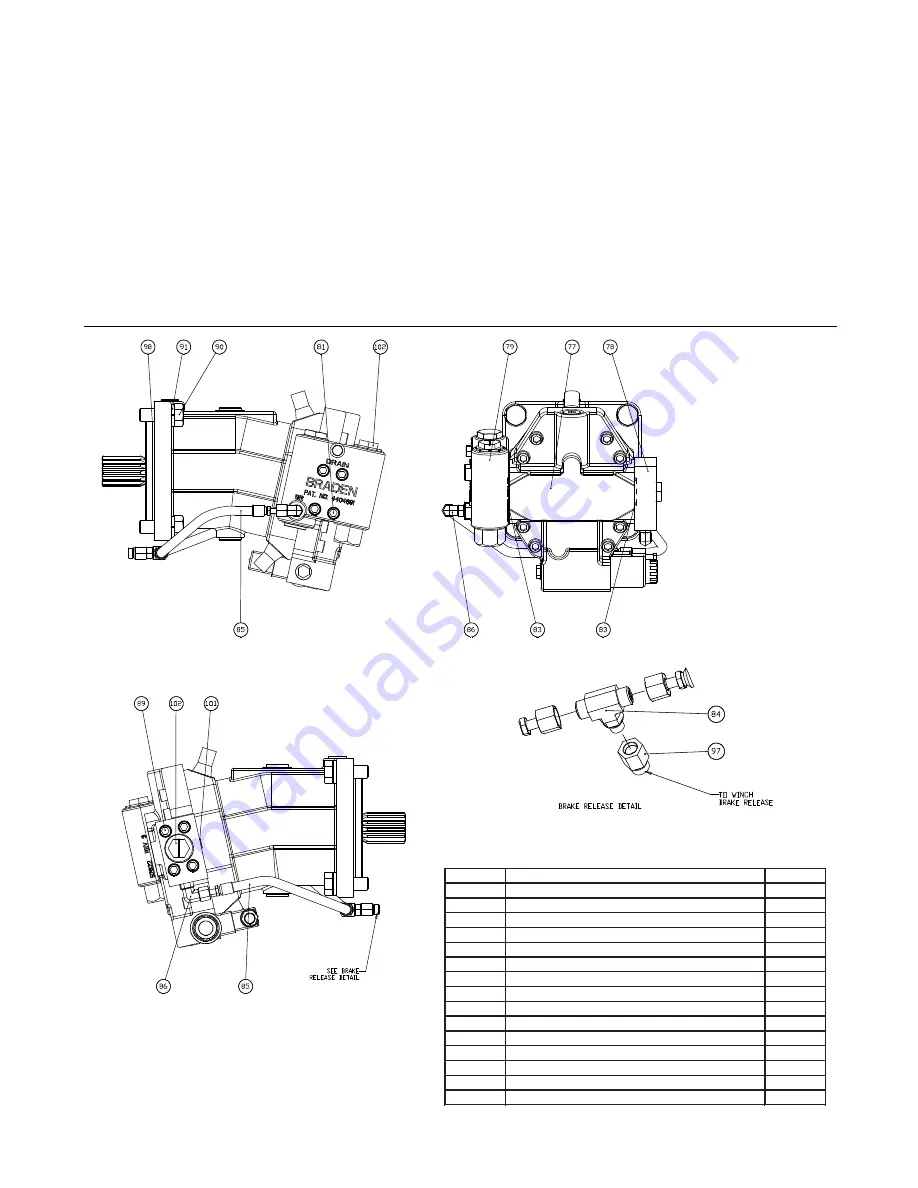

Motor Group

Item

Description

Quantity

77

Hydraulic Motor

1

78

Lowering Port Manifold

1

79

Braden Brake Valve

1

81

Socket Head Capscrew (7/16 - 14 x 3 Gd 8)

4

83

O-ring

2

84

T-ORFS, Brake Release Port

1

85

Hose, Brake Release

2

86

Elbow

2

89

Socket Head Capscrew (7/16 - 14 x 1

½

Gd 8)

4

90

Hex Head Capscrew (

¾

- 10 x 2 Gd 8 Z)

4

91

Lockwasher (

¾

)

4

97

Adapter, Brake Release Port

1

98

O-ring, Motor Pilot

1

101

Plug, -4 ORB

1

102

Shipping Plug

2

28