1

7

Daily

Weekly Monthly Yearly

Inspect wire rope and rigging

X

X

X

X

Inspect drum clutch and shift

mechanism for proper engagement

X

X

X

X

Inspect for external oil leaks

X

X

X

X

Check for damaged hoses / lines

X

X

X

X

Check for loose or missing bolts,

pins, keepers, or cotter pins

X

X

X

X

Check gear oil level / refill

X

X

X

Lubricate grease fittings

X

X

X

Inspect breather fitting

X

X

X

Inspect winch mounting fasteners -

torque as required

X

X

X

Inspect structural welds

X

X

X

Check hydraulic relief valve setting

X

X

Inspect hydraulic filters / strainers

X

X

Replace gear oil

See Notes

(1) and (2)

X

NOTES:

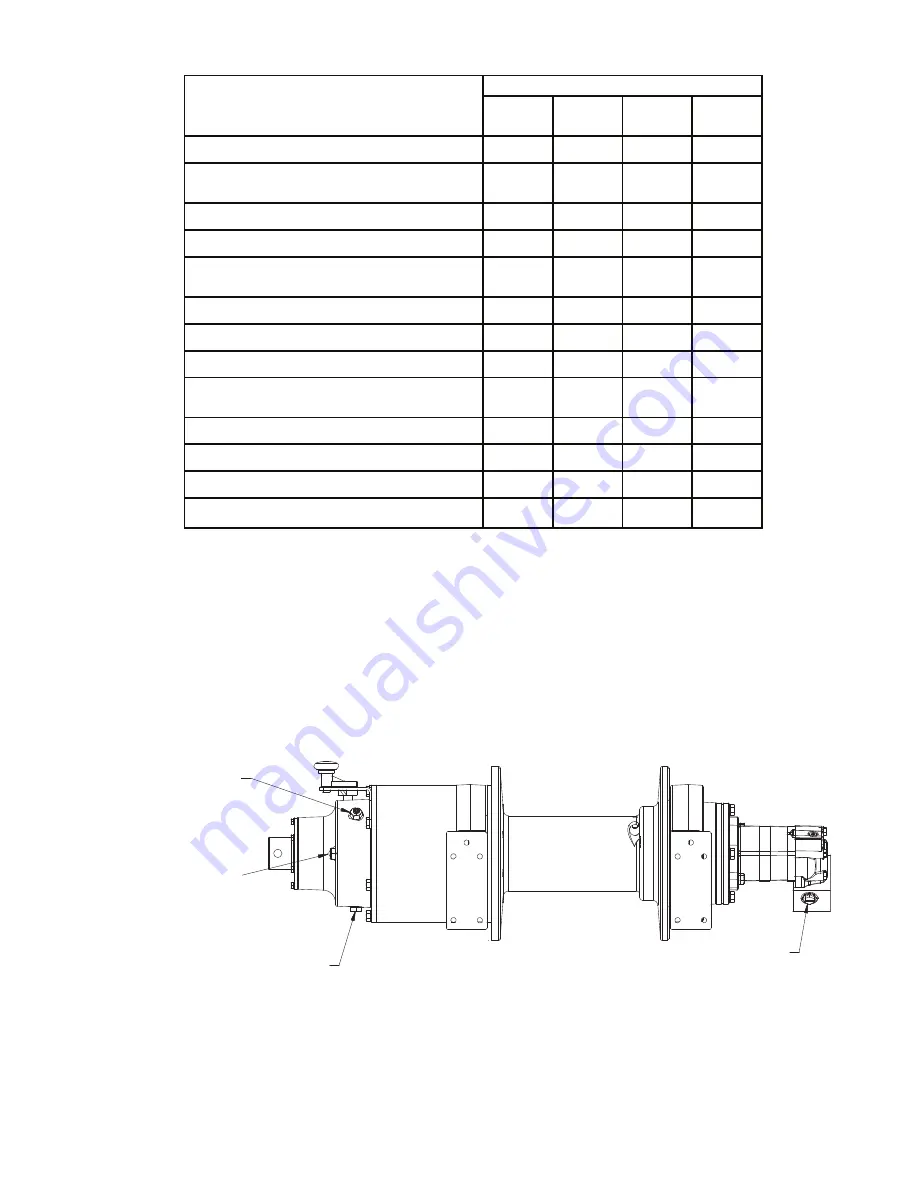

(1) Change the gear oil after the first 100 hours or 30 days of use,

whichever occurs first.

Inspection Interval

Inspection Performed

(2) For winch operation in excess of 50 hours per week, oil changes should

occur every 6 months instead of yearly.

OIL DRAIN

PLUG

OIL FILL

AND VENT

REEL OUT

PORT

OIL LEVEL

SIGHT GAUGE

Summary of Contents for Braden PD35A

Page 1: ...LIT2475 R3 Nov 2014 Printed in U S A For serial number location see page 3...

Page 39: ...39...

Page 40: ......