17

SERVICE PRECAUTIONS

After troubleshooting the winch and its hydraulic system as covered in the “Trouble Shooting” section of this manual,

and the problem is determined to be in the winch, use the following procedure to disassemble the winch as needed.

• Before any part is removed from the winch, all service instructions should be read and understood.

• Work in a clean, dust-free area, as cleanliness is of utmost importance when servicing hydraulic equipment.

• Use only genuine factory replacement parts, which may be obtained through your heavy equipment dealer. Never

re-use expendable items, such as O-rings.

• Inspect all machined surfaces for excessive wear or damage before reassembly operations start.

• Lubricate all O-rings and oil seals with clean gear oil prior to installation.

• Use a sealing compound on the outside surfaces of oil seals. If using a thread sealant on fasteners or fi ttings, avoid

getting excess sealant inside parts or passages that conduct oil.

• Thoroughly clean all parts in a good grade of safety solvent. Wear protective clothing as required.

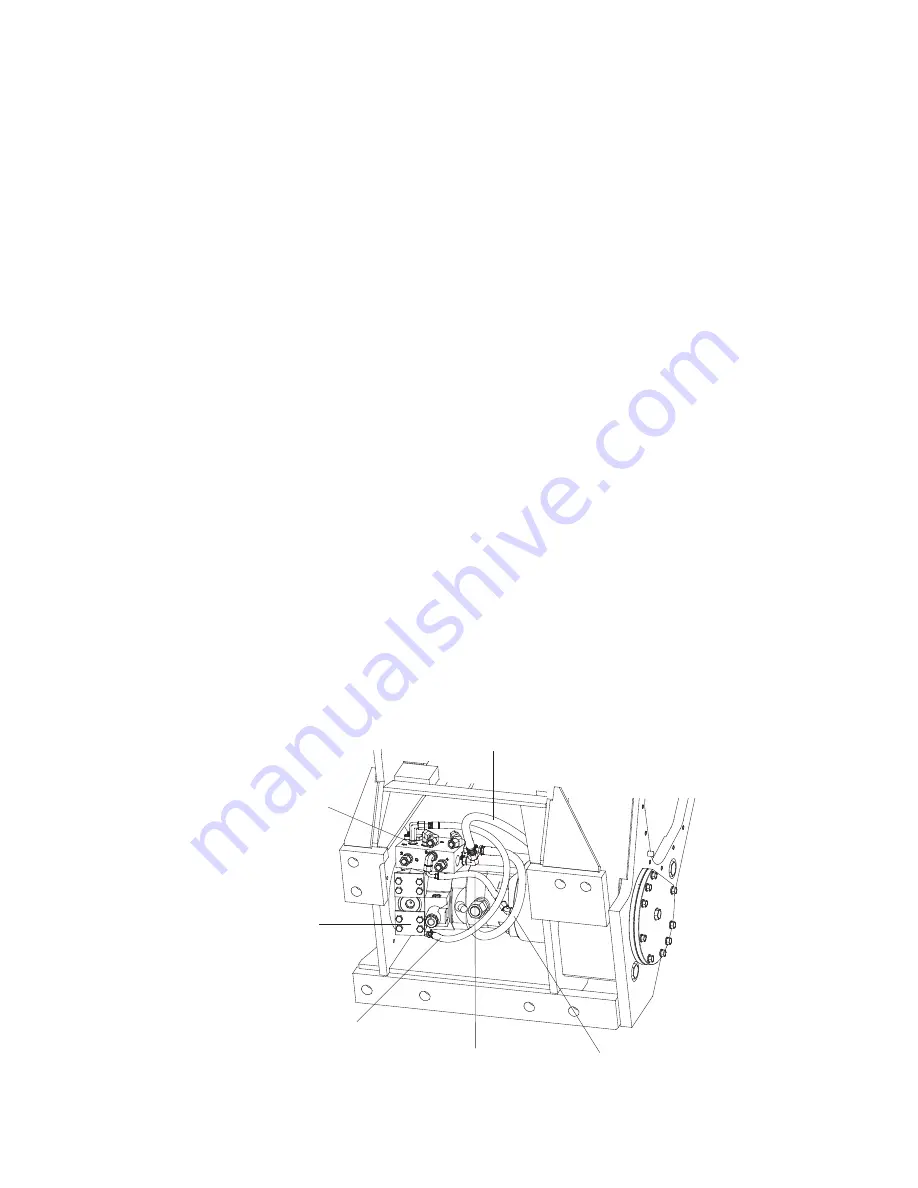

Hydraulic Motor Group

(Hydraulically Operated Winch Control Valve)

The typical hydraulic schematic is on pg.7

Contamination of the hydraulic system will shorten the life of the components and system. Work in a clean dust-free

area when servicing any part of the hydraulic system.

Freespool

Hose

Winch Control

Valve

Drive-Away

Valve

Drive-Away

Hose

Brake Release

Hose

Tank Hose