15

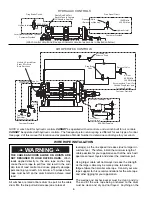

TROUBLE SHOOTING

TROUBLE

REMEDY

PROBABLE CAUSE

If a winch ever exhibits any sign of erratic operation, or load control difficulties (i.e. load creeping or chattering)

appropriate troubleshooting tests and repairs should be performed immediately. Continued operation in this manner

may result in property damage, serious personal injury or death.

A

The winch will not pay-out or haul-in

the load smoothly.

CAUTION

WARNING

!

!

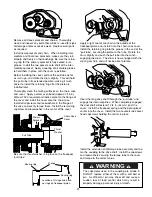

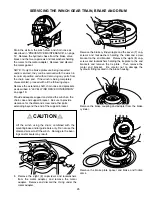

Disassemble brake to inspect

brake discs.

2.

Friction brake will not release as

a result of damaged brake

discs.

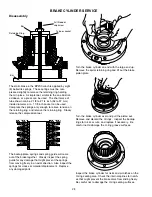

Check brake cylinder seal as

follows:

A. Disconnect the hose from the

brake valve block. Connect a

hand pump with accurate 0-

2,000 psi (13,800 kPa) gauge

and shut-off valve to the hose

(–4 J.I.C. fitting).

B. Apply 1,000 psi (6,900 kPa) to

the brake. Close shut-off valve

and let stand for five (5) min-

utes.

C. If there is any loss of pressure in

five (5) minutes, the brake cylin-

der should be disassembled for

inspection of the sealing sur-

faces and replacement of the

seals. Refer to “Motor Support-

Brake Cylinder Service”.

1.

The friction brake may not be

releasing as a result of a defec-

tive brake cylinder seal.

NOTE: If the brake cylinder seal

is defective the winch drum will

fill with hydraulic oil and slowly

fill the chain case. A fast leak

may cause oil to leak around the

motor end drum seal. A slower

leak may fill the chain case and

leak oil from the vent.

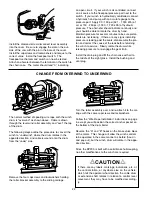

Oil leaks from vent plug.

Same as A1.

Peak intermittent system back

pressure must not exceed 150

psi (1,030 kPa). Inspect

hydraulic system for a restriction

in the return line from the control

valve and/or from the motor

case drain to the reservoir. Be

sure control valve and plumbing

is properly sized to winch motor.

Oil analysis may indicate con-

tamination has worn motor shaft

and seal. Thoroughly flush

entire hydraulic system and

install new filters and oil. Install

new motor seal.

1. Same as A1.

2. Motor seal may be defective as a

result of high system back pres-

sure or contaminated oil.

B

Summary of Contents for Braden BP200

Page 46: ......