17

TROUBLE

REMEDY

PROBABLE CAUSE

Same as remedies for Trouble D1.

Thoroughly clean exterior and flush

interior.

Fill/drain to proper level.

Same as remedies for Trouble D2.

Prime mover low on horsepower or

R.P.M. Tune/adjust prime mover.

Check suction line for damage.

If pump is belt driven, belts are slip-

ping. Replace/tighten belts.

Pump worn. Replace pump.

Disassemble winch to inspect and/or

replace worn parts.

1.

Same as D1.

2.

Be certain that the hydraulic

system temperature is not more

than 180 degrees F. Excessive

hydraulic oil temperatures may

be caused by:

A. Plugged heat exchanger.

B. Too low or too high oil level in

hydraulic reservoir.

C. Same as D2.

D. Hydraulic pump not operating

efficiently.

3.

Excessively worn or damaged

internal winch parts.

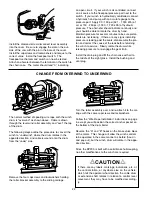

The winch runs hot.

E

F

The wire rope does not spool

smoothly on the drum.

Consult wire rope manufacturer

for recommendation of wire

rope that best suits your appli-

cation.

Replace wire rope and conduct

operator/rigger training as

required.

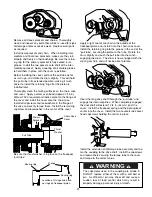

Roller assembly should lag

behind where the rope is laying

onto the drum by 1/2 a rope

diameter. Adjust as required.

1.

Could be using the wrong lay

rope. There is a distinct advan-

tage in applying rope of the

proper direction of lay. When the

load is slacked off, the several

coils on the drum will stay clos-

er together and maintain an

even layer. If rope of improper

lay is used, the coils will spread

apart each time the load is

removed. When winding is

resumed, the rope has a ten-

dency to criss-cross and overlap

on the drum. The result is often

flattened and crushed rope.

2.

The winch may have been over-

loaded, causing permanent set

in the wire rope.

3.

Levelwind roller assembly may

be out of adjustment

Summary of Contents for Braden BP200

Page 46: ......