24

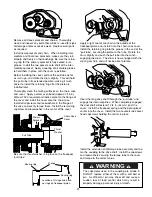

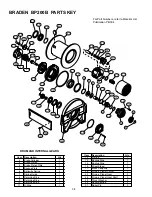

Support the diamond screw and remove the level wind

support bracket from the winch and slide the carrier

assembly off of the slide bars. The slide bars can now

be removed, if required, by driving out the rollpin at the

chain case end. If the bearing or seal on the chain case

end of the diamond screw need to be replaced, the

chain case cover must be removed. Refer to “Level

Wind Drive Coversion” on page 19. With the chain case

cover removed, remove the chain, sprocket and bushing

from the diamond screw. Remove the retaining ring

from the diamond screw bearing. Support the diamond

screw and gently tap the diamond screw out of the end

bracket. The bearing and seal can now be replaced.

Install the diamond screw, bearing and retaining ring.

Thoroughly clean and inspect the support bracket for

signs of damage. Inspect and replace the seal in the

bracket if required. Thoroughly clean and inspect the

bearing, and replace if required.

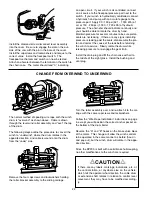

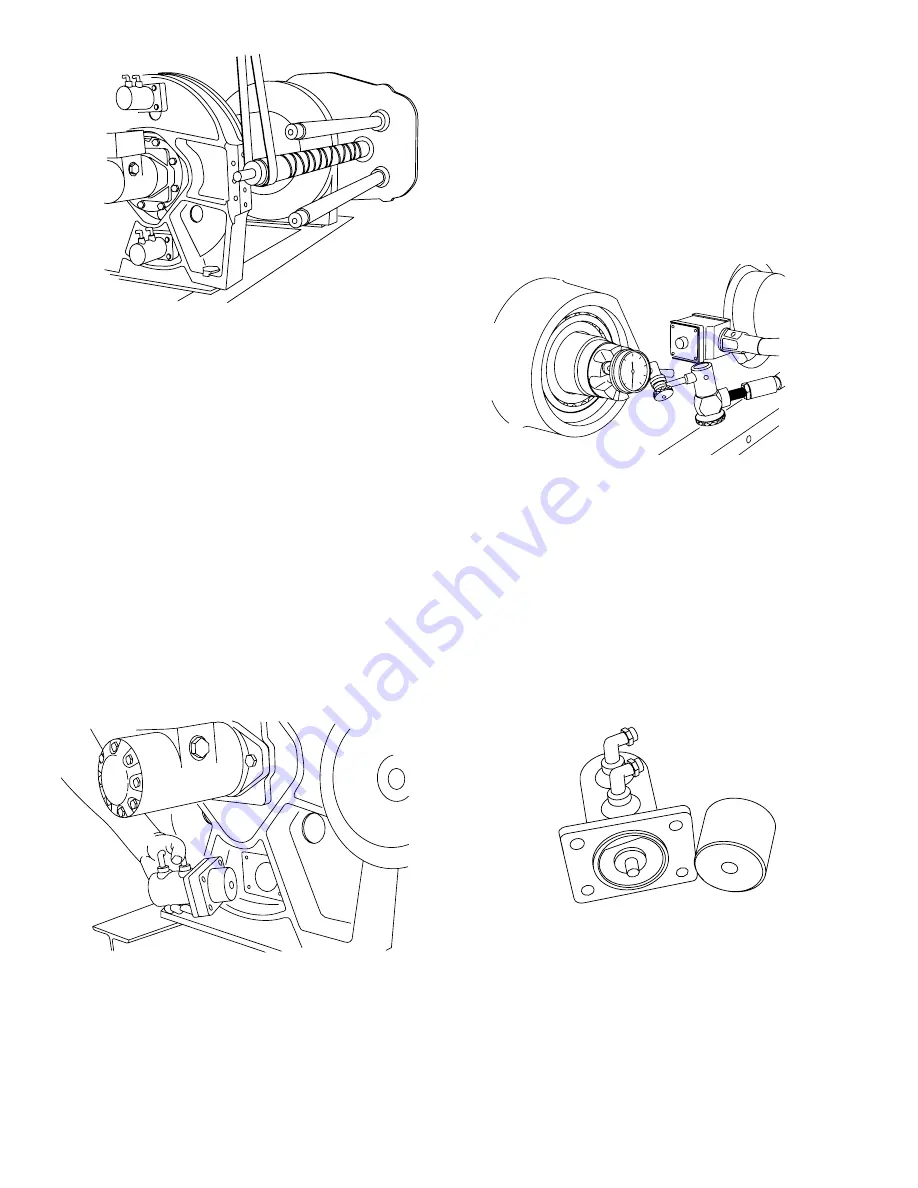

There are two drag brake cylinders on BP200B winches,

one above, and one below the motor. Both are serviced

in the same manner. Early model BP200 winches have

only one cylinder.

Remove the lines from the drag brake cylinder. Remove

the four (4) capscrews and lockwashers holding the

cylinder to the end bracket and remove the cylinder.

Remove the worn brake disc from the cylinder. Inspect

the cylinder for signs of oil leakage and/or physical dam-

age. Replace the cylinder if required.

Install a new brake disc onto the cylinder rod.

Check the surface of the drum flange that the brake disc

rubs against to be sure it is free of any rust, burrs, deep

grooves, etc. that might damage the new brake disc.

Re-install the cylinder onto the winch end bracket and

re-connect the lines to it.

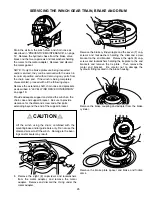

Check diamond screw end play with a dial indicator.

End play should be between 0.010 and 0.015 in. (0.25 -

0.38 mm). Adjust end play with shims under the hand-

wheel cover. Apply grease through the grease fitting to

fill the bearing cavity. Install the handwheel and rollpin.

Disengage the diamond screw and rotate the handwheel

to be sure the diamond screw and carriage operate

smoothly. Install the bushing, sprocket and chain onto

the end of the diamond screw. Install the chain case

cover as described in “Level Wind Drive Coversion” on

page 21.

REPLACING THE DRAG BRAKE DISCS

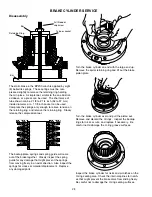

Clean the diamond screw and slide tubes and lightly

lubricate their entire lengths. Slide the carrier assembly

onto the slide bars and engage the pawl with the dia-

mond screw. Lightly lubricate the sealing surfaces of

the diamond screw and the handwheel shaft. Install the

support bracket onto the winch, being careful not to

damage the seal as it engages the diamond screw.

Install all capscrews and lockwashers and torque to their

correct values. Apply a liberal coating of grease to the

bearing cup and cone. Install the spacer washer, bear-

ing cup and cone, and the cover and shims.

Summary of Contents for Braden BP200

Page 46: ......