28

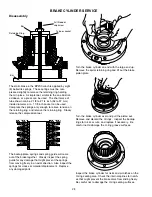

BRAKE CYLINDER SERVICE

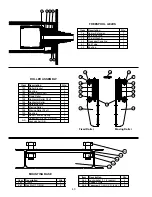

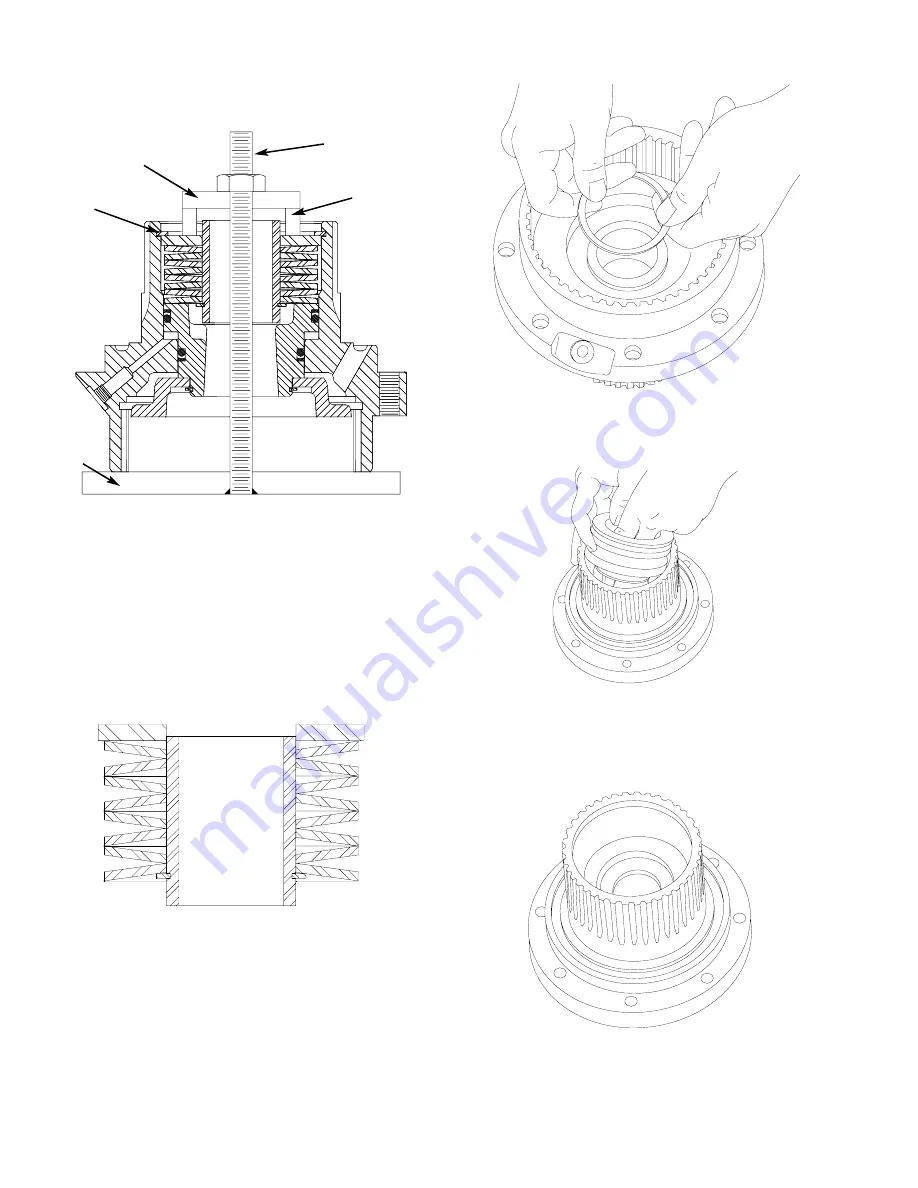

Disassembly

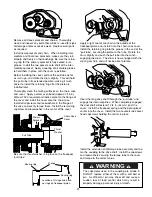

The static brake in the BP200 winch is applied by eight

(8) belleville springs. These springs must be com-

pressed slightly to remove the retaining ring holding

them in place. A simple tool, similar to the one illustrat-

ed above, or a press can be used. The short piece of

tube shown can be 2 1/8 to 2 1/4 inch (54 to 57 mm)

inside diameter, or a 1 1/8 inch socket can be used.

Compress the springs only enough to relieve tension on

the retaining ring, and remove the retaining ring. Slowly

release the compression tool.

Tube or socket

Bar

Bar

All thread or

capscrew

Retaining Ring

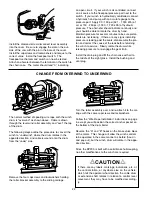

The backup plate, springs and spring guide will come

out of the brake together. Closely inspect the spring

guide for any damage that might prevent the springs

from moving freely in an axial direction. Also inspect the

springs for cracks or material displacement. Replace

any damaged parts.

Turn the brake cylinder on end with the large end up.

Remove the spiral retaining ring and lift out the brake

piston plate.

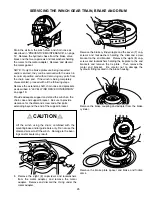

Inspect the brake cylinder for nicks and scratches on the

O-ring sealing area. Check the internal splines for notch-

es that might prevent the brake discs from sliding freely.

Be careful not to damage the O-ring sealing surfaces.

Turn the brake cylinder over and pull the piston out.

Remove and discard the O-rings. Inspect the backup

rings for nicks or cuts, and replace if necessary. Be

careful not to damage the O-ring groove surfaces.

Summary of Contents for Braden BP200

Page 46: ......