7

end of the wire rope to keep it from fraying (i.e. tape or

wire) must not be in contact with the wedge when the

installation is complete. Consult the wire rope manufac-

turer on the proper treatment of the dead end of the wire

rope. Some rope manufacturers recommend when using

rotation resistant wire rope, that the rope end be seized,

welded or brazed before inserting the wire rope into the

wedge socket to prevent core slippage or loss of rope lay.

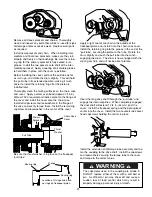

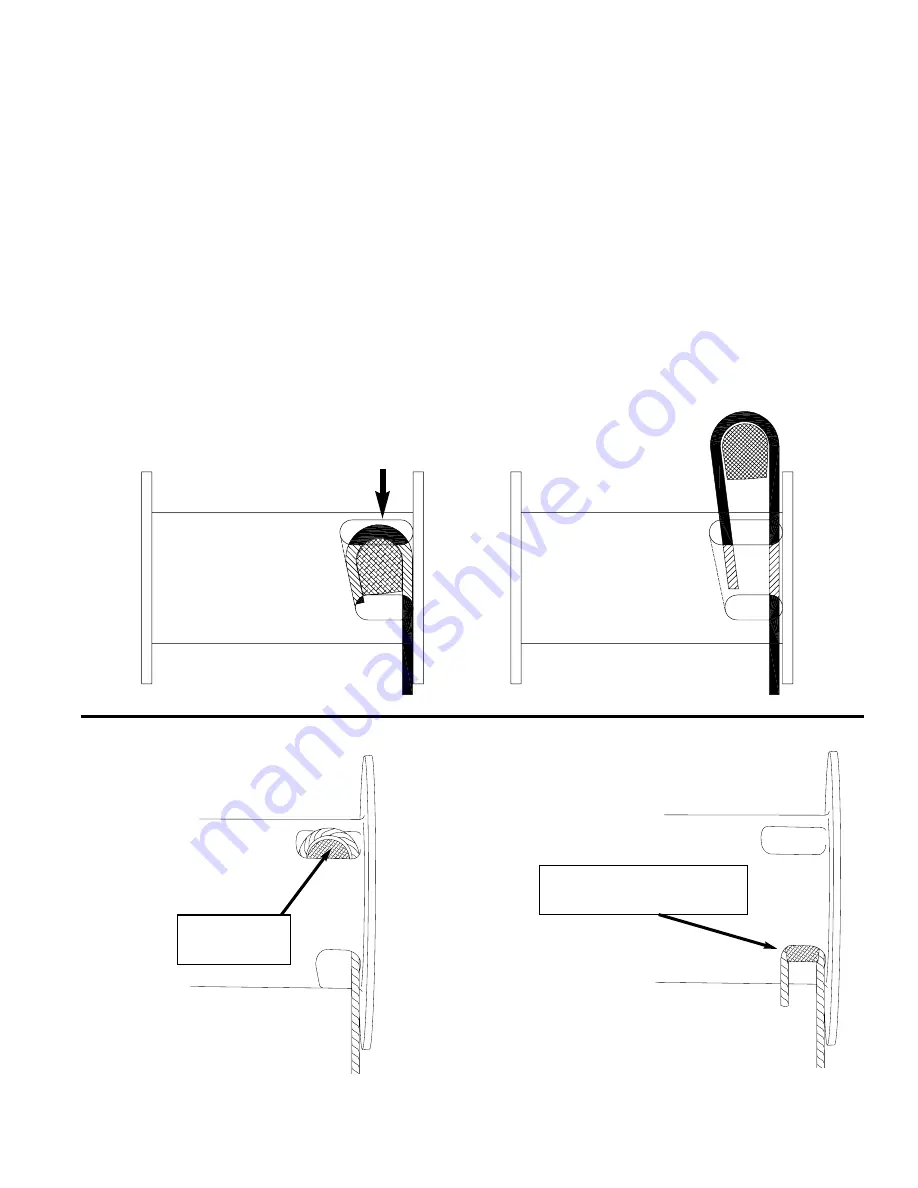

Take the free end of the wire rope and insert it through the

small opening on the cable drum. Loop the wire rope and

push the free end about 3/4 of the way back through the

pocket. Install the wedge as shown in figure 7, then pull

the slack out of the wire rope. The “dead” end of the rope

needs to extend slightly beyond the end of the wedge as

shown in figure 8.

Using a hammer and brass drift, drive the wedge as deep

into the pocket as possible to ensure it is fully seated and

no further movement is detected. Applying a load on the

wire rope will also help seat the wedge in the pocket.

Check to ensure the wedge does not protrude from either

end of the pocket, causing it to interfere with proper

spooling of wire rope onto the drum (see figures 9 & 10).

If there is interference or the wedge does not seat firmly,

contact the Braden Product Support Department at 918-

251-8511 to determine the proper wedge size. The

wedge shipped from the factory will properly anchor 7/16,

1/2 and 9/16 inch wire rope.

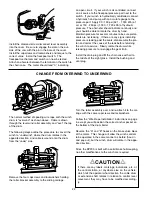

Before installing the wire rope, the levelwind roller brack-

et must be aligned with the correct rope pocket. Rotate

the drum until the correct cable pocket is on top at the

12:00 position. The correct pocket will have the smaller

Drive from

this side

Wedge and wire rope

fully seated in pocket

Correct Installation

Figure 7

Figure 8

Wedge not

fully seated

Wedge pulled too far

through anchor pocket

• Wire rope not tight against wedge

• Wedge may be too large

• “Dead” end of wire rope and/or wedge may

interfere with proper spooling

• Wedge may be too small

Figure 9

Figure 10

Incorrect Installations

Summary of Contents for Braden BP200

Page 46: ......