26

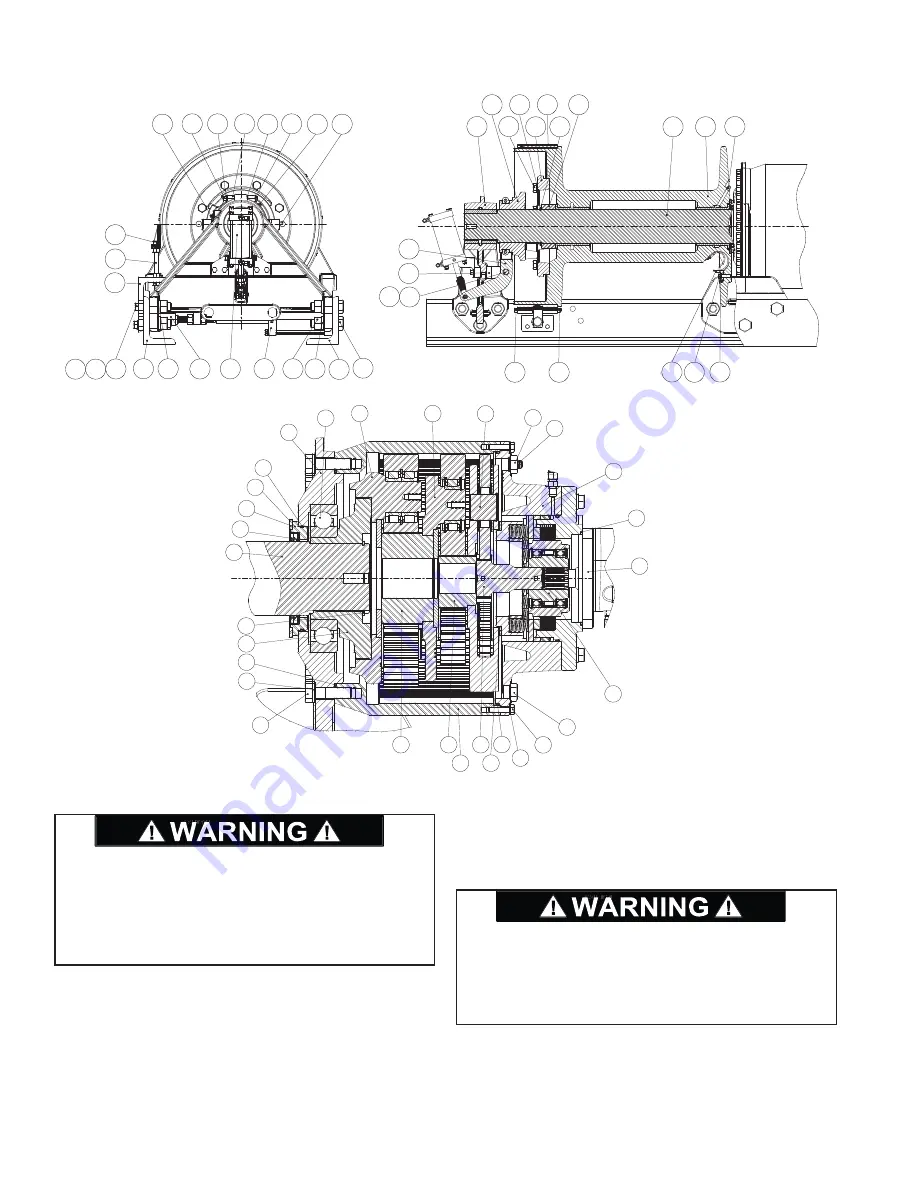

DISASSEMBLY

1. Remove the wire rope from the winch and drain the

gear oil from the winch by removing the drain plug on

the bottom of the winch gearbox. Remove the fi ll/vent

plug to speed draining.

2. Take precautions to collect hydraulic oil and remove

the hydraulic hoses connected to the winch motor and

disconnect the brake release hose from the winch

brake release port. Ensure there are no external hose

connections to the winch motor then remove the mo-

tor by removing the four capscrews securing it to the

winch.

3. Remove the overrunning clutch assembly (600) from

the brake cylinder assembly (500).

4. The remaining disassembly is most easily done with

the winch standing on the support end. Blocks should

be placed under the support end bearing leg so that

the winch rests level on the base angles on one side

and blocks under the bearing leg on the other side.

The HP125B winch weighs approximately 1800 lbs (817

kg). Ensure all lifting equipment including the overhead

hoist and rigging have adequate capacity. Use of lifting

equipment that does not have adequate lifting capac-

ity or is not properly maintained may result in personal

injury or death.

67

68

45

96

95

102

58

98 99

38

101

80

23

103

104

75

81

76

18

1

73

88

5

78

800

79

76

83

68

48

49

56

76

63

88

77

74

23 86

6

84

87

89

WINCH DISASSEMBLY

400

300

200

500

600

700

41

54

29

35

34

3

2

64

69

12

4

14

7

65

72

24

39

82

61

33

1

60

23

36

The winch planet carrier assemblies and brake cylinder

assembly weigh up to 100 lbs (46 kg) each. Ensure the

hoist and rigging are rated for this weight. Using a hoist

or rigging with insuffi cient rating may result in personal

injury or death.

Summary of Contents for BRADEN HP125B

Page 2: ...2...