26

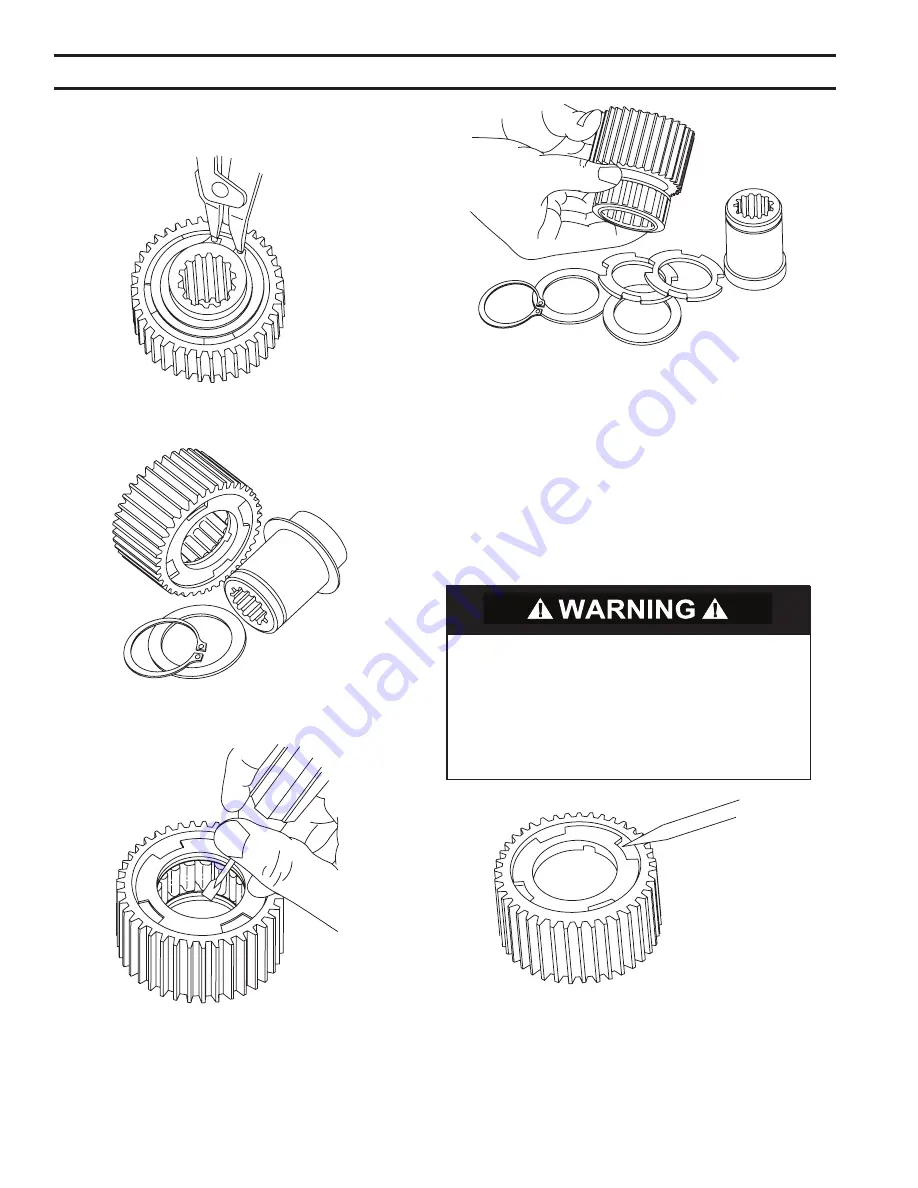

DISASSEMBLY

1. Remove the snap ring and sprag bushing retainer from

one end only.

2. Pull the inner race out. Examine the race for scoring, wear

or indentations caused by the sprag cams.

3. Use a screwdriver and mallet to remove the sprag bush-

ing from one end of the outer race. There are four special

cut-outs in the bushing for this purpose. Be careful not to

damage the bushing inside surface. If a bushing’s inside

surface is damaged or shows wear, replace it.

4. Next, slide the sprag clutch out, inspect the sprag clutch

closely for abnormal wear, cracks, pitting or corrosion.

Check small clips for breakage or bright spots; the signs of

excessive wear. Unless the outer race or remaining sprag

bushing is damaged or shows excessive wear, there is no

need for further disassembly. If disassembly is necessary,

remove the bushing according to the procedure covered

in Step 3. All brake clutch assembly parts should be thor-

oughly cleaned and inspected before assembly.

ASSEMBLY

1. Press a sprag bushing into the outer race, using a me-

chanical or hydraulic press. A flat plate of approximately

the same diameter as the bushing flange outside diameter

should be placed between the press and bushing during

assembly to protect the bushing. Be certain the bushing

flange is against the shoulder in the outer race.

The polished surfaces of the races and sprag cams must

be perfectly smooth to insure positive engagement of the

clutch. The slightest defect may reduce brake clutch effec-

tiveness, which may lead to loss of load control and result

in property damage, personal injury, or death. It is gen-

erally recommended to replace the entire brake clutch as-

sembly if any component is defective.

BRAKE CLUTCH SERVICE