9

AUTOSPEED MODE

From the operator’s perspective, this is the normal and

most simple winch control method.

The winch line speed, or drum rotation speed, may be

controlled by moving the control lever a small distance or

by operating the tractor engine, and therefore the tractor

implement pump, at a lower RPM.

NOTE:

Operating the tractor engine at the lowest idle set-

ting while winching may result in erratic winch operation.

Always operate the tractor at high engine idle to provide

the full range of performance from the winch and the

smoothest control. Operating the engine at lower settings

will NOT provide slower controlled winching.

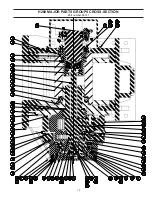

The hydraulic motor used with the autospeed control sys-

tem is a variable displacement, piston-type motor with an

internal load-sense circuit. This circuit contains a small

piston which adjusts the angle of the motor rotating group

from minimum to maximum displacement as the pressure

THEORY OF OPERATION

on the work ports (A and B) increases due to the load ap

-

plied to the winch gear train. When there is little or no load

on the winch, the motor rotating group will remain at the

preset minimum displacement. As the winch load increas-

es, the pressure at the motor work ports will increase. This

same pressure will also act on the load-sensing system in

the motor. As the load-sensing system experiences more

pressure, it increases the motor displacement to provide

increased torque, or pulling power, at a slower line speed.

In this manner, the motor displacement will automatically

adjust to provide the maximum hydraulic horsepower for

any given line speed and line pull situation.

LOW-SPEED LOCK MODE (LOW LOCK)

Depressing the button near the top of the control lever will

force the variable displacement motor to shift the piston

to the maximum displacement position, which will allow

the winch to operate in the maximum line pull, minimum

line speed mode, to enhance precise load control. When

shifted into LOW-LOCK, an indicator light on the main

operator instrument panel will remain lit. To disable LOW

LOCK, and return to autospeed mode, press the button

again. The indicator light will be off.

WINCH LOCK-OUT

Winch lock-out is available on some but not all CAT doz-

ers. If your model is equipped for lock-out, a toggle switch

located on the operator’s right console adjacent to the

winch control lever may be switched to completely lock out

the hydraulic signal to the winch. This can be performed

during servicing, or to eliminate the possibility of acciden-

tal winch actuation when performing general dozing op-

erations. When activated, an indicator light on the main

operator instrument panel will remain lit.

DO NOT

use the drum clutch release (DRIVE-AWAY)

for controlled reeling out of suspended loads. Sudden

release of a load may result in property damage, in-

jury, or death. Use only

REEL-OUT

to lower any load.

!

WARNING

!

Never exceed

4 mph (6.4 km/hour)

relative speed be-

tween the tractor and the load while in DRIVE-AWAY

mode. This relative limit applies when the tractor and/

or the load are moving. Limiting the tractor to either

first or second gear typically prevents reaching ex

-

cessive speed only when the tractor is moving. If the

load and the tractor are moving, tractor and/or load

speed must be reduced so that relative speed does

not exceed the speed limit. Exceeding this relative

speed limit will cause the part of the winch power train

connected in DRIVE-AWAY to reach damaging back-

driven rotational speed and cause catastrophic winch

failure, damage to property connected to winch, other

property damage, personal injury, or death.

CAUTION

!

!

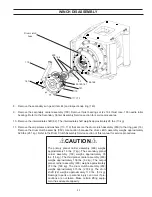

The hydraulic motor and gear ratio is configured to

match the hydraulic system of a specific tractor. It

may not be possible to mount the winch onto a dif-

ferent tractor model. Installation onto a tractor with

a higher flow hydraulic system could result in over

-

speed damage to the motor and winch gear train.

The maximum drum RPM in autospeed, no-load, with

a piston motor, is listed below:

H200 500:1 9 RPM (+0, -1)

CAUTION

!

!