Section 6

Body Mounting

6-2

12/11

Body Mounting Using Brackets

Always install a spacer between the body subframe and the top flange of the frame rail.

Failure to do so could result in corrosion due to dissimilar materials.

Installation of a spacer between the body subframe and the top flange of the frame rail will help prevent premature wear

of the components due to chafing or corrosion.

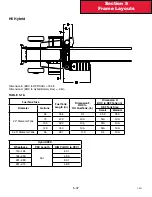

Frame Sill

If the body is mounted to the frame with brackets, we recommend that the frame sill spacer be made from a strip of rub-

ber or plastic (delrin or nylon) . These materials will not undergo large dimensional changes during periods of high or low

humidity. The strip will be less likely to fall out during extreme relative motion between body and chassis. See Figure 6–3.

Body Subframe

(Rail)

Chassis Frame

(Rail) Sill

Spacer

FIGURE 6-3.

Spacer Between Frame Sill and Body Rail - Rubber or Plastic

Brackets

When mounting a body to the chassis with brackets, we recommend designs that offer limited amount of relative move

-

ment, bolted securely but not too rigid. Brackets should allow for slight movement between the body and the chassis. For

instance, Figure 6–4 shows a high compression spring between the bolt and the bracket .

Spring

Rubber

Spacer

FIGURE 6-4.

High Compression Spring

FIGURE 6-5

. Rubber Spacer Between Brackets

Between the Mounting Bolt and Upper Bracket

Another possibility is mounting a rubber spacer between the brackets . See Figure 6–5 .

These designs will allow relative movement between the body and the chassis during extreme frame racking situations.

Extreme frame racking, with rigid mountings, could cause damage to the body . This is particularly true with tanker

installations .

CAUTION:

Summary of Contents for Kenworth T170 2011

Page 1: ...Kenworth T170 T270 T370 and Hybrid 2011 Body Builders Manual...

Page 2: ......

Page 10: ...12 11 Section 1 Introduction Page Intentionally Left Blank...

Page 52: ...Section 3 Dimensions 3 34 12 11 Automatic Transmission Allison 3000RDS...

Page 53: ...3 35 Section 3 Dimensions 12 11 Manual Transmission...

Page 111: ...Section 5 Frame Layouts 5 40 12 11 Page Intentionally Left Blank...

Page 120: ...Section 6 Body Mounting 6 9 12 11 Page Intentionally Left Blank...

Page 128: ...Section 7 Frame Modifications 7 8 12 11 Page Intentionally Left Blank...

Page 165: ...Section 8 Electrical 8 37 12 11 FIGURE 8 31 Cab Load Center mPDC...

Page 170: ...Section 8 Electrical 8 42 12 11 Page Intentionally Left Blank...

Page 179: ...12 11 Kenworth Truck Company P O Box 1000 Kirkland WA 98083 425 828 5000...