Page

18 of 39

Number

SM001-300

HVAC: Idle Management System

Appendix

A. Battery Condition and Performance

Battery Voltage is critical for system operation. Special

attention should be given to both sets of batteries.

NOTE

Poor quality batteries or a weak alternator will have a

negative impact on unit run time. Always maintain the

best possible batteries and charging system.

Load test and maintain batteries as required by the man-

ufacturer.

Battery symbol in diagnostics screen indicates battery

health. This is created after many cycles. If batteries

have been disconnected recently this symbol will reset.

Several cycles will be needed to get accurate battery

health.

B. Fan and Temperature Control Display

With the control off: check for 12 VOLT at and from F1 10

amp fuse to the connector on rear of control, terminal 1.

Terminal 7 is negative. Check for 12 volts at control termi-

nal 6 (wake up) coming from the main/ compressor con-

troller terminal D6. Pushing the control (on) will switch

this input from the main controller to ground at the control

panel. This signals the main control to start the system.

When control is on the wake up signal should be less

than 1 volt.

C. Relay Testing

With relay unplugged, confirm there is 12 VOLT on the

sockets where 85 and 30 relay terminals are connected.

If you do not have 12 VOLT here check fuses, wiring and

battery connections.

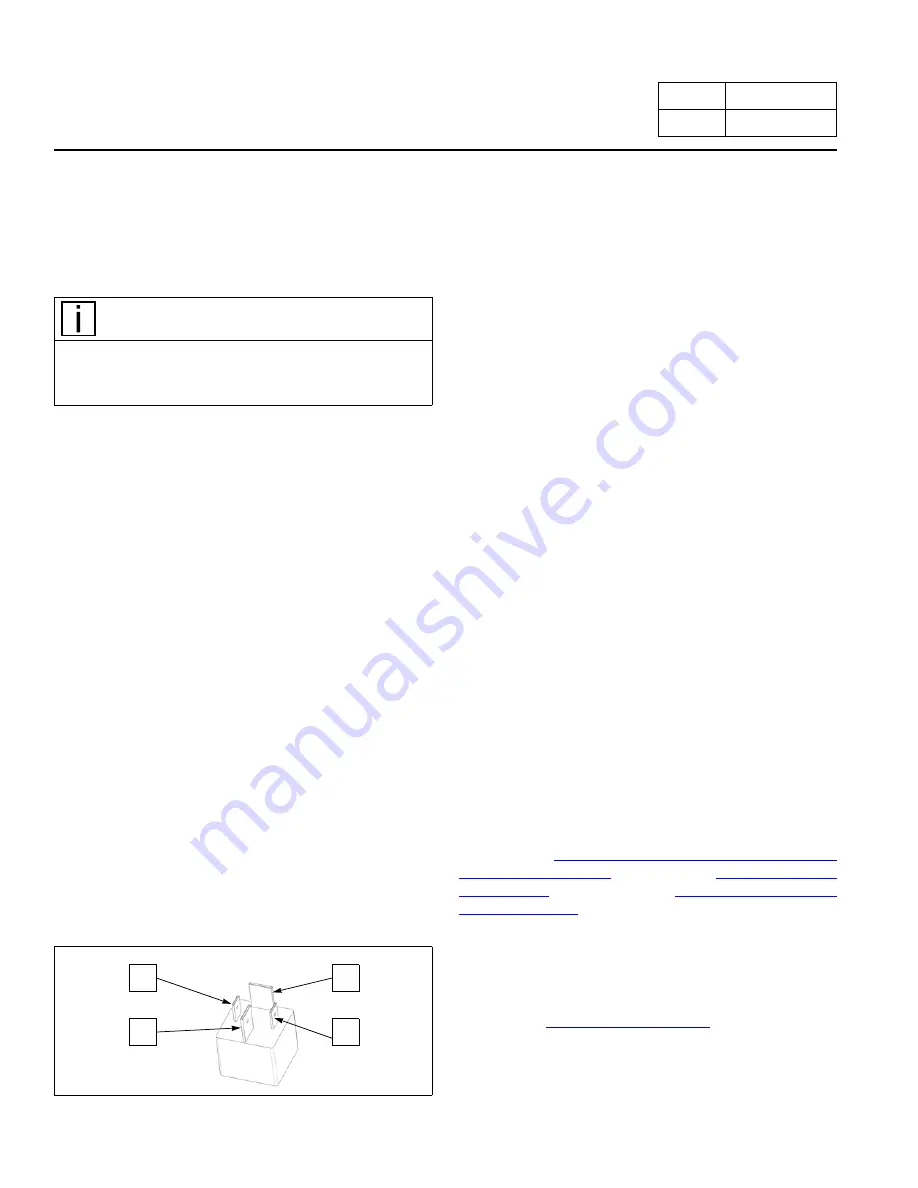

Figure 15.

Relay Testing

87

86

85

30

Now, with relay unplugged, check across terminals 85

and 86 of the relay, using an OHM meter. You should

have approximately 90 ohms + or - 10% at 68°F (20°C).

This is measuring the resistance through the relay coil. If

you do not, replace relay.

Overview

When you turn the EHVAC unit on, if all safety switches

are okay, such as the high pressure switch, temperature

sensor / freeze switch and the compressor thermal limit

switch, the Main / Compressor controller will connect the

compressor relay, condenser fan relay and the evapora-

tor blower relay terminals 86 to ground at their respective

terminals D10, D11 and D12 at the controller. This will

close the contacts 30 and 87 of all 3 relays and allow

power to each component.

You should now have 12 VOLT passing through the

relays on spade terminals 87. This provides power to

fuses F2, F3 and F4, continuing to the Linear Power

Module, evaporator blower, condenser fan and the com-

pressor controlling section of the Compressor Controller

Assembly.

With relay plugged in: turn the unit on. If you do not have

12 VOLT on terminal 87, check across terminals 85 (+)

an 86 (-). You should have 12 VOLT. If you do not, you

may have a defective harness or system controller. If you

have 12 VOLT here and do not have 12 VOLT on termi-

nal 87 your relay is defective. The internal coil of the relay

is energized but the contacts are not closing. Replace the

relay.

If you have 12 VOLT on terminal 87 and the compressor,

condenser fan or evaporator blower does not run you

could have a defective component such as evaporator

blower, condenser fan or compressor controller.

See testing “

J. Evaporator Blower Motor and Linear

D. Pressure Switch Testing

You must remove top covers to access the switch.

The brazed “

” on page 12 is not

removable. This switch is normally closed. When the unit

is off for a few minutes, unplug the System Controller and

check between pins D2 and D5, you should always have

continuity. If you do not, you may have a broken wire, bad