- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲

I

NSTRUCTION

M

ANUAL

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: pace@metallographic.com Web: http://www.metallographic.com

31

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

NANO 1000T / FEMTO 1500

Polishing Head

can control the aggressiveness of the

grinding/ polishing operation.

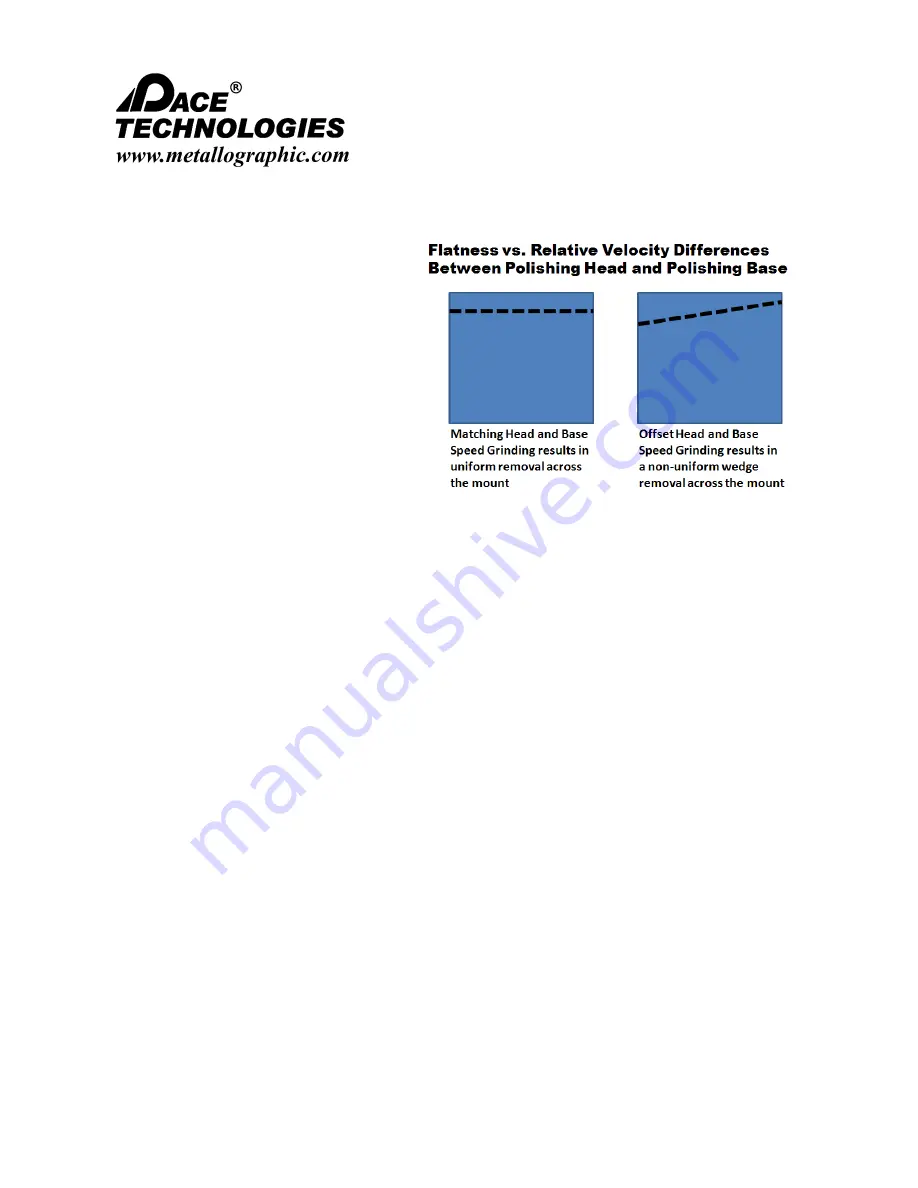

It is also very important for polishing

machines which use individual force

pistons for applying the polishing force to

run the power head and base at closely

matching speeds and in the

complementary direction. If these

machines are run with significantly different

speeds or direction the mount will have a

tendency to grind with a wedge and

therefore it will not be square.

Grinding Pressure

Grinding / polishing pressure is dependent upon the applied force (pounds or Newton's) and the area

of the specimen and mounting material. Pressure is defined as the Force/Area (psi, N/m

2

or Pa). For

specimens significantly harder than the mounting compound, pressure is better defined as the force

divided by the specimen surface area. Thus, for larger hard specimens, higher grinding / polishing

pressures increase stock removal rates. However, higher pressure also increases the amount of

surface and subsurface damage produced in the specimen.

Note regarding SiC grinding papers: as the abrasive grains dull and cut rates decrease, increasing

grinding pressures can extend the life of the SiC paper.

Higher grinding / polishing pressures can also generate additional frictional heat which may be

beneficial for the chemical mechanical polishing (CMP) of ceramics, minerals and composites.

Likewise for extremely friable specimens (such as nodular cast iron), higher pressures and lower

relative velocity distributions can aid in retaining inclusions and secondary phases.

Grinding Direction

The orientation of the specimen can have a significant impact on the preparation results, especially for

specimens with coatings. In general, when grinding and polishing materials with coatings, the brittle

component should be kept in compression. In other words, for brittle coatings, the direction of the

abrasive should be through the coating and into the substrate. Conversely, for brittle substrates with

ductile coatings, the direction of the abrasive should be through the brittle substrate and into the

ductile coating.

Manual Preparation

In order to ensure that the previous rough grinding damage is removed when grinding by hand, the

specimen should be rotated 90 degrees and continually ground until all of the scratches from the

previous grinding direction are removed. When necessary, the abrasive paper should be replaced with

a newer paper to maintain cutting rates.