- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲

I

NSTRUCTION

M

ANUAL

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: pace@metallographic.com Web: http://www.metallographic.com

32

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

NANO 1000T / FEMTO 1500

Polishing Head

The purpose of the rough polishing step is to remove the damage produced during cutting and planar

grinding. Proper rough polishing will maintain specimen flatness and retain all inclusions or

secondary phases. By eliminating the previous damage and maintaining the microstructural integrity

of the specimen at this step, a minimal amount of time is required to remove the cosmetic damage at

the final polishing step.

Rough polishing is accomplished primarily with diamond abrasives ranging from 9 micron to 1

micron. Polycrystalline diamond -- because of its multiple and small cutting edges -- produces high

cut rates with minimal surface damage. Therefore, polycrystalline diamond abrasives are

recommended for metallographic rough polishing on low-napped polishing cloths.

5.10.2 Rough Polishing

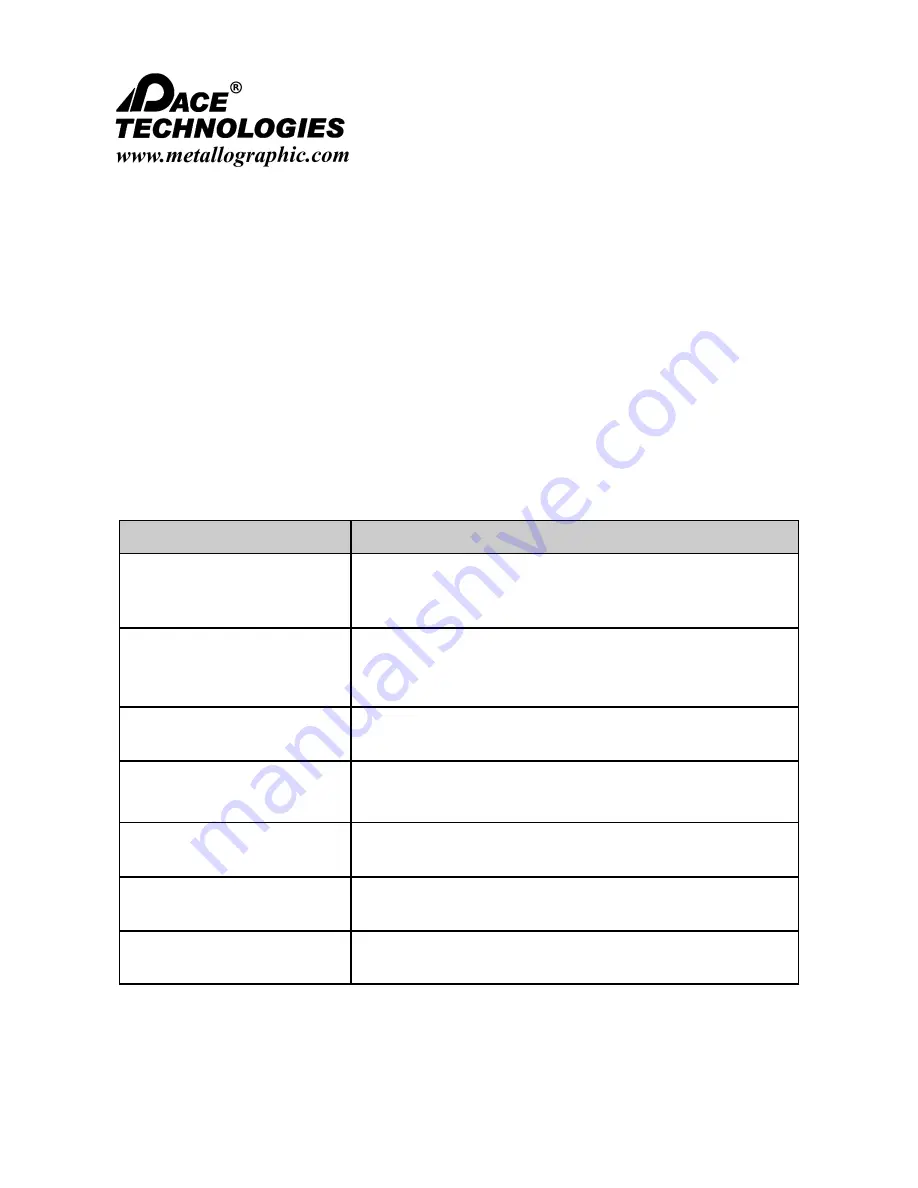

Rough Polishing Guidelines

Material

Recommendations

Metals (ferrous, non-ferrous,

tool steels, superalloys, etc.)

Rough polishing typically requires two polishing steps, e.g., a 6-

micron diamond followed by a 1-micron diamond on low-napped

polishing cloths.

Ceramics and ceramic matrix

composites (CMC)

Low-nap polishing pads using polycrystalline diamond, alternating

with colloidal silica. This provides a chemical mechanical

polishing (CMP) effect which results in a damage-free surface

Polymer matrix composites

(PMC)

Diamond-lapping films are recommended.

Biomaterials

Low-napped polishing pads with polycrystalline diamond,

alternating with colloidal silica. Alternatively, diamond-lapping

films may work well.

Microelectronic specimens

Diamond-lapping films are recommended.

Plastics and polymers

800 and 1200 grit SiC abrasive paper are recommended.

Plasma spray materials

Diamond-lapping films or low-napped polishing pads with

alternating diamond and colloidal silica abrasives.