- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲

I

NSTRUCTION

M

ANUAL

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: pace@metallographic.com Web: http://www.metallographic.com

38

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

NANO 1000T / FEMTO 1500

Polishing Head

CLASS 3 Polishing Procedures

5.11.3 Cast Irons

Cast irons are difficult materials to prepare properly because the

graphite nodules (or graphite flakes) are easily pulled out during

preparation. By minimizing the sectioning damage and by

starting with a modest-grit-size SiC paper, retaining these difficult

particles can be accomplished.

Abrasive/surface

Lubricant

FEMTO pressure

setting (psi)

Head / Wheel speed

Time

120 grit SiC paper*

240 grit SiC paper*

Water

5-10 lbs

200/200 rpm

Until plane

1 minute 1 minute

360 grit SiC paper

600 grit SiC paper

800 grit SiC paper

1200 grit SiC paper

Water

5-10 lbs

200/200 rpm

1 minute

1 minute

1 minute

1 minute

1 um DIAMAT diamond on

GOLDPAD pad

DIALUBE

Purple Extender

5-10 lbs

200/200 rpm

2 minutes

0.05 um Nanometer alumina

on TRICOTE pad

5-10 lbs

100/100 rpm

1 minute

* Recommended for Central Force holders (this step not required for Individual Force holders)

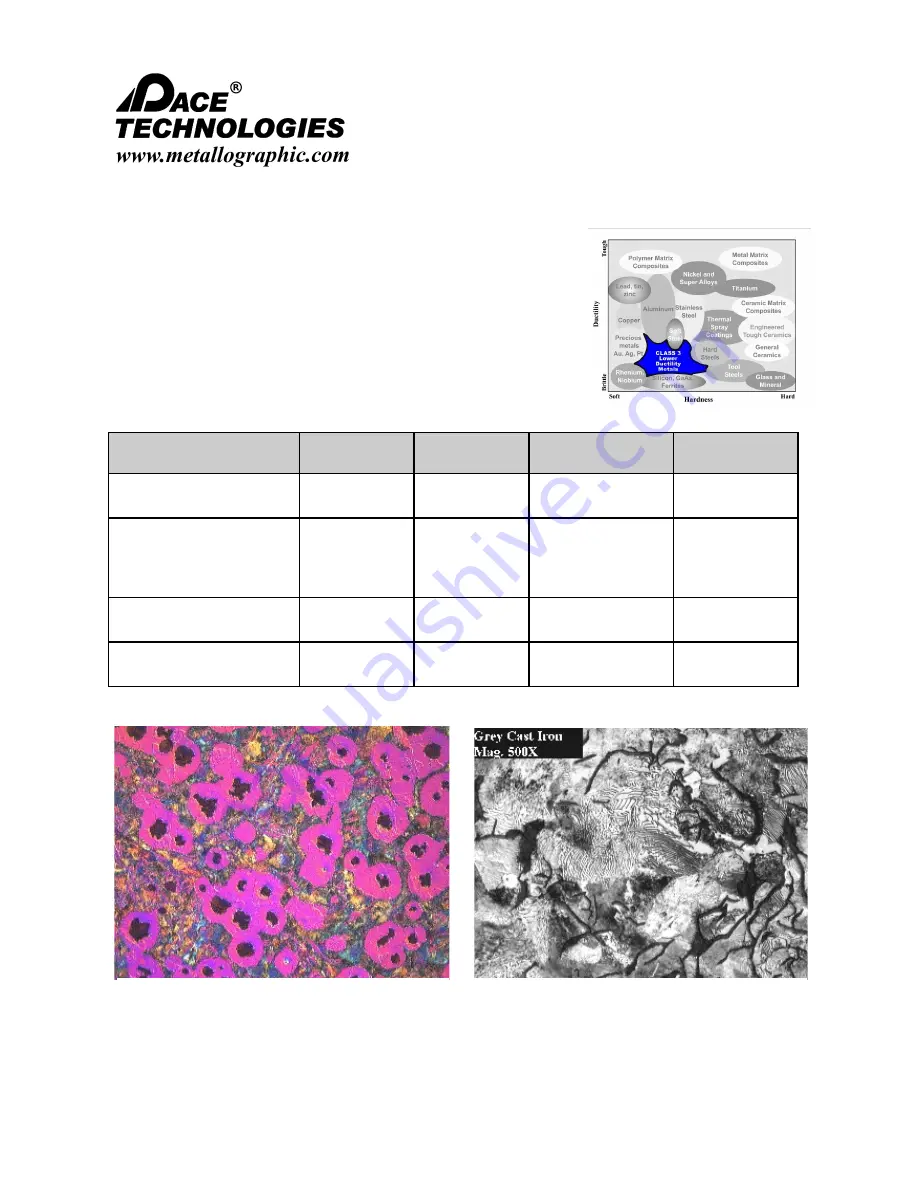

Nodular Cast Iron

microstructure, Etchant 2%

Nital, Mag. 100X

Graphite Cast Iron

microstructure, Etchant 2%

Nital, Mag. 500X