- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲

I

NSTRUCTION

M

ANUAL

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: pace@metallographic.com Web: http://www.metallographic.com

39

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

NANO 1000T / FEMTO 1500

Polishing Head

CLASS 4 Polishing Procedures

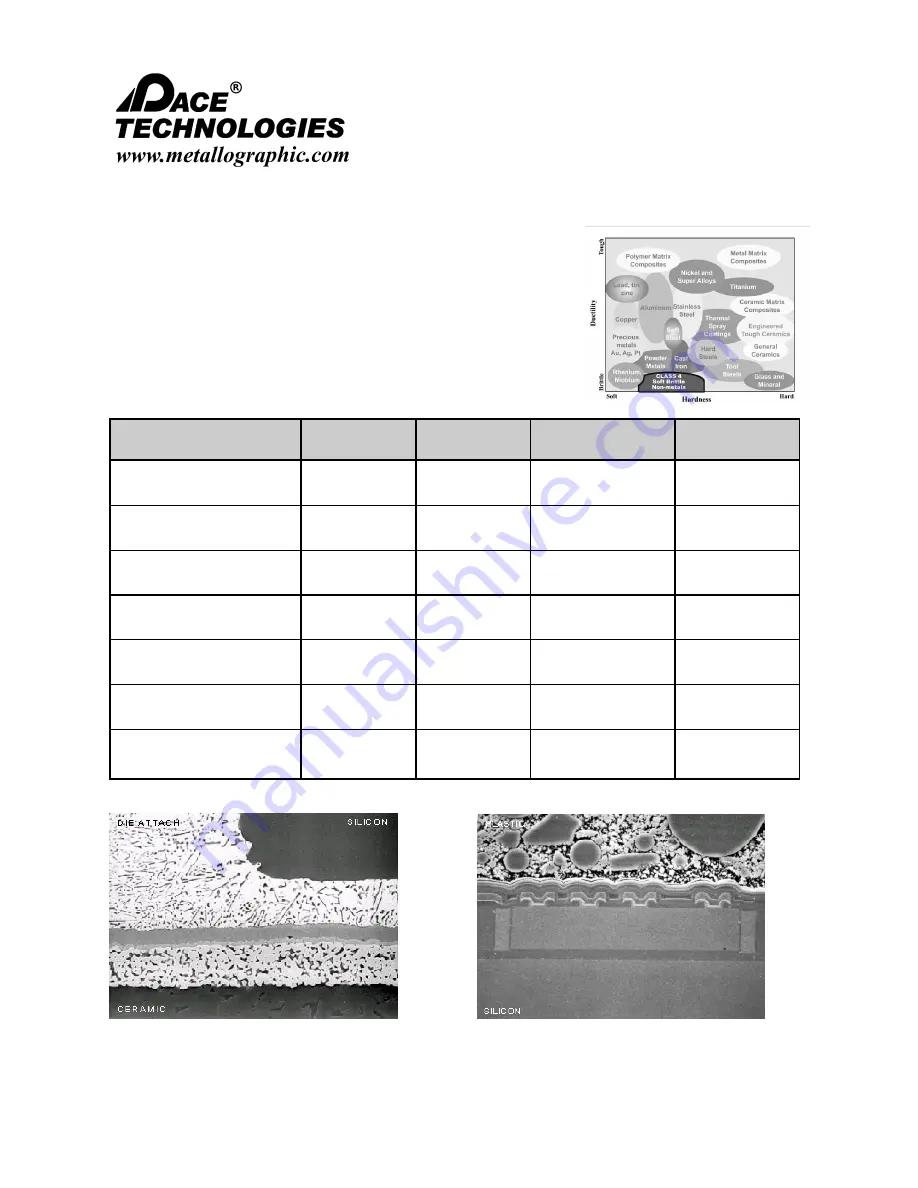

5.11.4 Microelectronics

The microstructural preparation of electronic packages presents some very

difficult challenges, such as abrasives embedding in very soft solder joints,

edge rounding, polishing relief between very hard (ceramic) or brittle

(silicon) materials and the very soft plastic and metal solders. The use of

alumina lapping films are very useful for maintaining flatness and for

minimizing fractured abrasive embedding for non-ceramic substrates. For

specimens with ceramic substrates, diamond lapping films are recommended.

Abrasive/surface

Lubricant

FEMTO pressure

setting (psi)

Head / Wheel speed

Time

30 micron alumina lapping

film*

POLYLUBE

Extender

5-10 lbs

100/100 rpm

Until plane

15 micron alumina lapping

film*

POLYLUBE

Extender

5-10 lbs

100/100 rpm

1-2 minutes

9 micron alumina lapping

film

POLYLUBE

Extender

5-10 lbs

100/100 rpm

1-2 minutes

6 micron alumina lapping

film

POLYLUBE

Extender

5-10 lbs

100/100 rpm

1-2 minutes

3 micron alumina lapping

film

POLYLUBE

Extender

5-10 lbs

100/100 rpm

1-2 minutes

1 um DIAMAT diamond on

ATLANTIS polishing pad

DIALUBE

Purple Extender

5-10 lbs

100/100 rpm

1-2 minutes

SIAMAT colloidal silica on a

MICROPAD polishing pad

5-10 lbs

100/100 rpm

1 minute

* Recommended for Central Force holders (this step not required for Individual Force holders)

Electronic die cross section

Electronic die cross section