- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲

I

NSTRUCTION

M

ANUAL

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: pace@metallographic.com Web: http://www.metallographic.com

46

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

NANO 1000T / FEMTO 1500

Polishing Head

CLASS 11 Polishing Procedures

5.11.11 Glass and Minerals

Glasses and minerals are generally fairly hard and have a tendency

to fracture. Proper specimen preparation requires that the damage

during specimen preparation be minimized, even as early as the

sectioning or cutting operation.

Abrasive/surface

Lubricant

FEMTO pressure

setting (psi)

Head / Wheel speed

Time

30 um DIAMAT diamond

suspension on CERMESH Metal

Mesh cloth

5-10 lbs

200/200 rpm

Until plane

9 um DIAMAT diamond on

POLYPAD polishing pad

5-10 lbs

200/200 rpm

3 minutes

3 um DIAMAT diamond on

TEXPAN polishing pad

SIAMAT

colloidal silica

5-10 lbs

200/200 rpm

3 minutes

0.05 micron NANOMETER

alumina on TRICOTE polishing

pad

5-10 lbs

100/100 rpm

1 minute

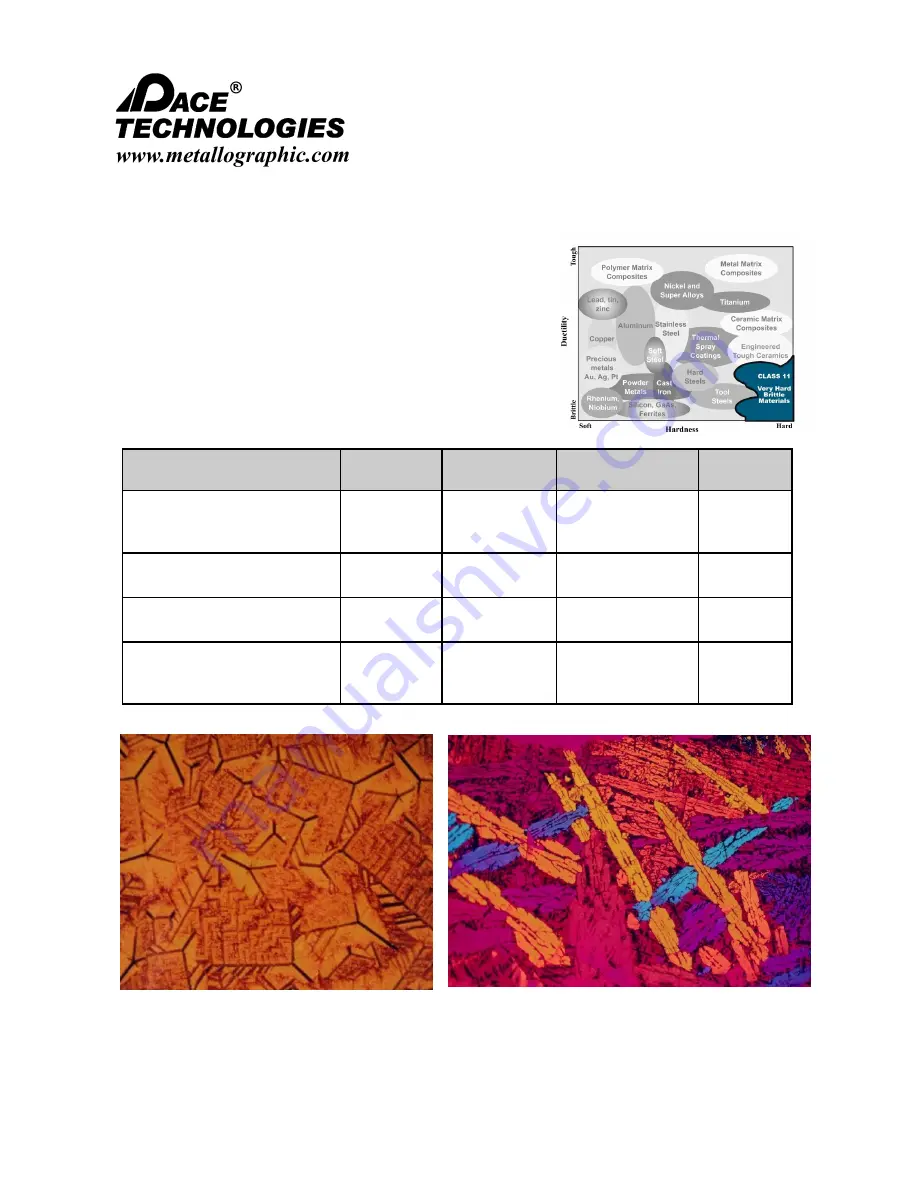

Alumino-silicate glass ceramic, 400X (Polarized

light) as polished

Slag, 100X (Polarized light), as polished condition