- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲

I

NSTRUCTION

M

ANUAL

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: pace@metallographic.com Web: http://www.metallographic.com

54

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

NANO 1000T / FEMTO 1500

Polishing Head

Polycrystalline diamond is a synthetic diamond which

provides better surface finishes and higher removal rates

than monocrystalline diamond. The following are the

advantages of a polycrystalline diamond over a

monocrystalline diamond:

Higher removal rates (self-sharpening abrasive)

Very uniform surface finish

More uniform particle size distribution

Harder / tougher particles

Blocky - shaped particles

Hexagonal (equally hard in all directions)

microcrystallites

Extremely rough surface (more cutting points)

Surface area is

300%

greater than with a

monocrystalline diamond

No abrasion-resistant

directionality (abrasion

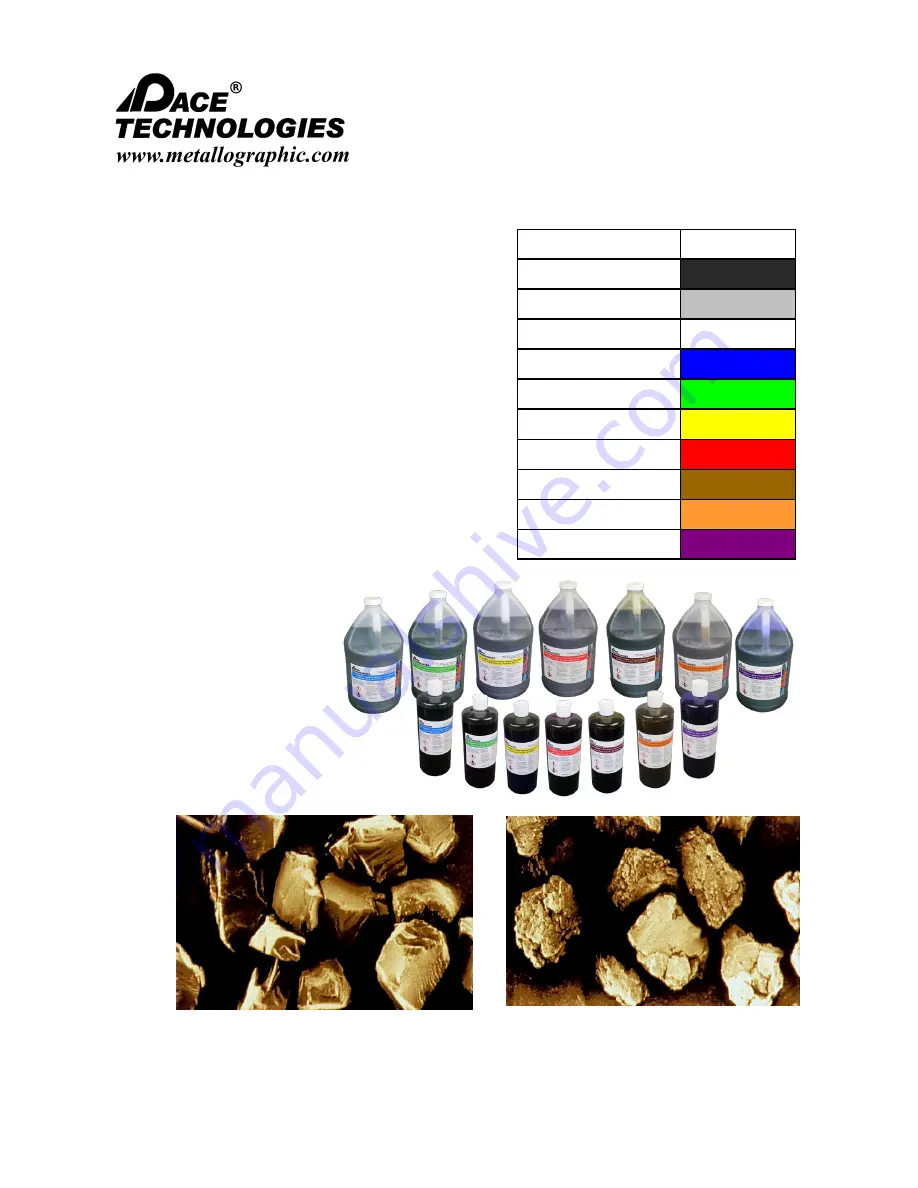

Diamond Size (um)

Color code

0.10

Charcoal

0.25

Gray

0.50

White

1.0

Blue

3.0

Green

6.0

Yellow

9.0

Red

15

Brown

30

Orange

45

Purple

Monocrystalline blocky - diamond

Polycrystalline multi-faceted diamond

8.5 Polycrystalline Diamond Abrasives