- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲

I

NSTRUCTION

M

ANUAL

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: pace@metallographic.com Web: http://www.metallographic.com

4

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

NANO 1000T / FEMTO 1500

Polishing Head

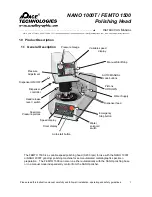

1.4 Single Force vs. Central Force Comparison

Note:

With independent pistons, initial grinding can be done with finer abrasives, thus reducing the

number of grinding steps. For flatter specimen preparation a central force polishing system (FEMTO

1500 or FEMTO 2500) are recommended.

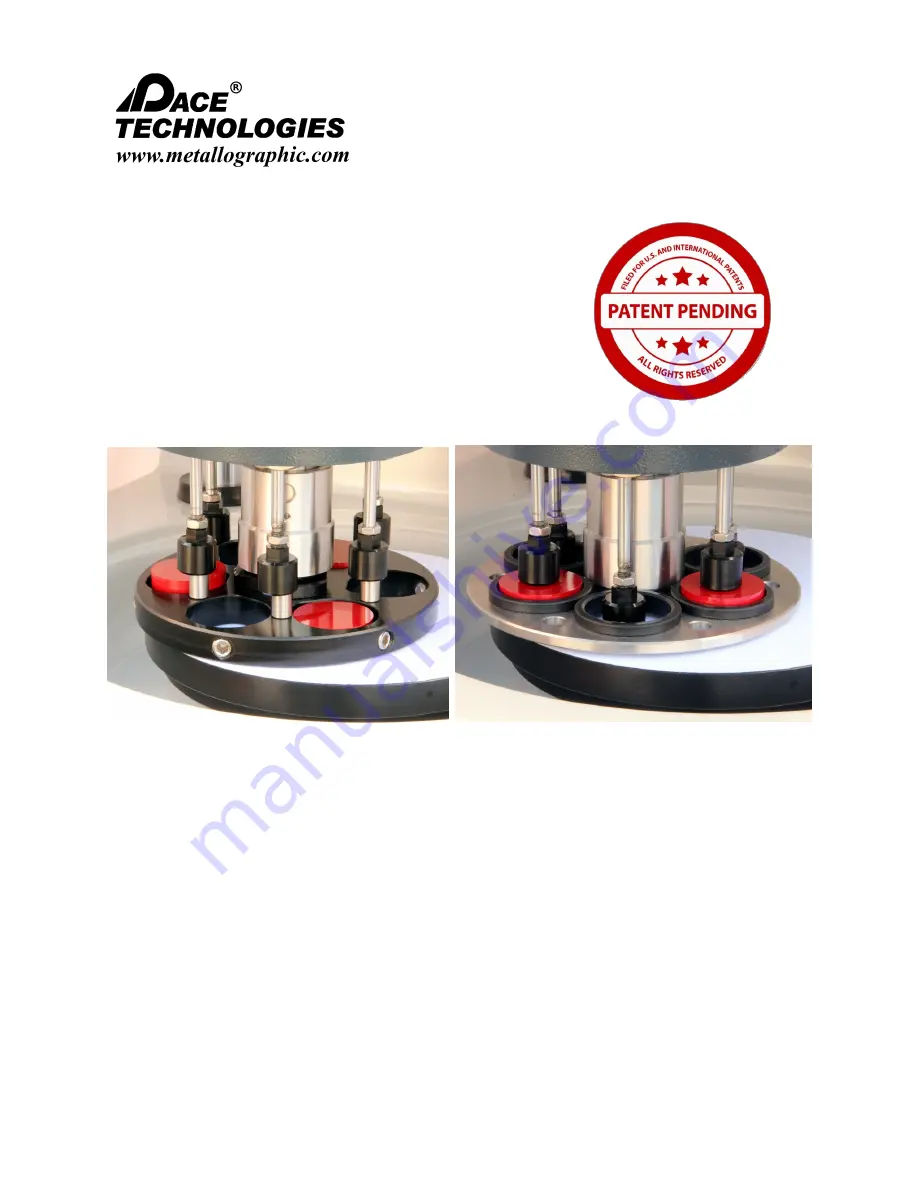

Central Force:

The individual pistons apply the

polishing force to the landing pads and pushes

down the holder through the spring loaded

central male coupler. For central polishing a

minimum of three samples locked into the holder

is required; however, flatness is then fixed over

all the mounted specimens

Individual Force:

Individual specimen force can

be applied using the Quick Release Chuck system

by screwing down the outside of the coupler so as

to lock the specimen mounting plate into a rigid

plane. This set-up allows for the individual holder

to be removed and cleaned. This holder also

eliminates the need to re-plane the samples if they

Single Force vs. Central Force Polishing Machines

Metallographic semi-automated polishing machines are available with

individual/ single specimen loading or with a fixed central holder. The

main advantage for using a central force holder is that the overall

specimen flatness is better. The primary advantages for individual

specimen holders are fewer required grinding/ polishing steps and

the ability to re-polish samples without the need to re-planarize the