NANO 1000S Polisher

I

NSTRUCTION

M

ANUAL

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: pace@metallographic.com W eb: https://www.metallographic.com

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

35

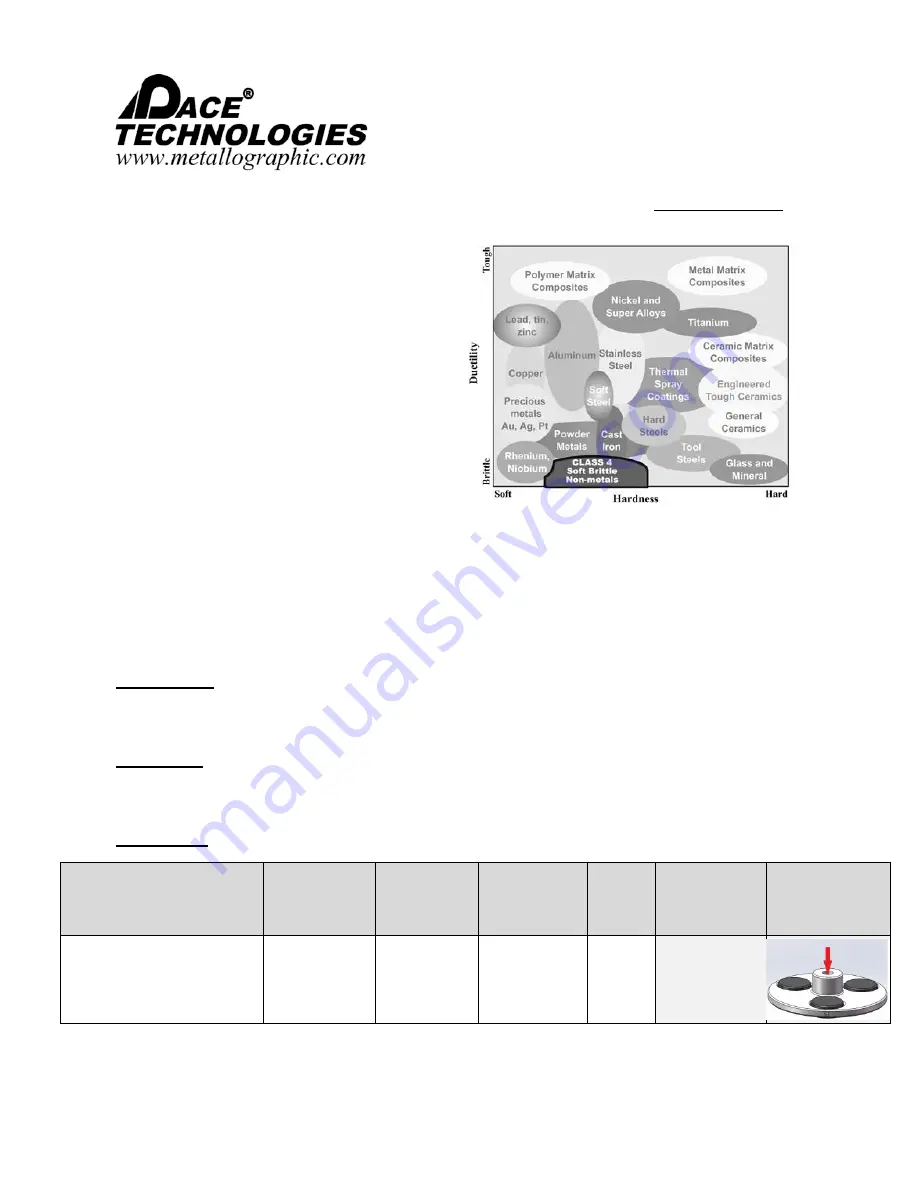

4.8.3.4 CLASS 4: Soft, Brittle, Non-Metals

(Example: Silicon Substrate Electronic)

Abrasive / Surface

Lubricant

Force /

Sample

Speed

(Head /

Base)

Time

Individual

Force

Mode

Central

Force Mode

3-

μ

m Diamond

Lapping Film*

POLYLUBE

Diamond

Extender

5

– 10 lbs.

200 / 200

rpm

Planar

N/A

Sectioning:

Diamond Wafering Blade

– Fine Grit / Low Concentration

Mounting:

Hot melt tape or castable mounting with Epoxy or Acrylic resins.

Polishing:

Specimen preparation of friable or

brittle materials such as silicon offer a

microstructural preparation challenge.

Proper microstructural preparation of

these materials must minimize

fracturing the silicon structure. This

is accomplished by first by cutting or

sectioning with fine grit / low

concentration diamond blades.

Oftentimes microelectronic cross

sections are not encapsulated and

just mounted using a hot melt tape. If the specimens are encapsulated, a

castable mounting compound such as an acrylic or an epoxy is recommended.

Initial grinding and polishing with diamond lapping films is required to prevent

undue damage to the silicon during grinding. Rough polishing is accomplished

on low napped polishing cloths using diamond, with final polishing for a very

short time on a high napped cloth using colloidal silica.