System Operations Manual, Rev B

www.paceworldwide.com

Page 11 of 21

NOTE:

Read the “Programming Your System” sections of this manual to utilize the full

capabilities of the system.

LED Display, Normal Operation

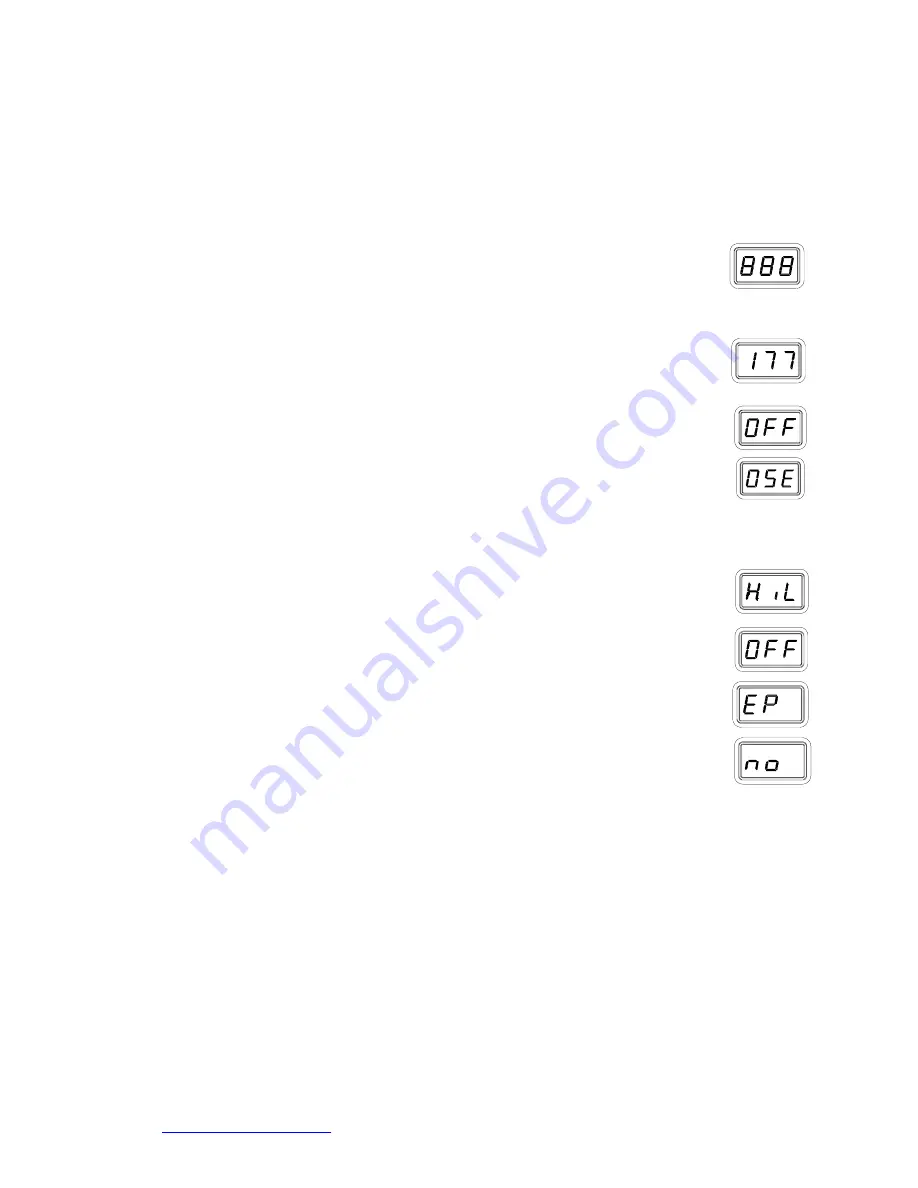

The LED Display provides a 3-digit display of temperature information. The LED Display will show:

1. A display of "888" on initial power up to ensure that all LEDs on the display are

working.

2. A display of the software version of the installed microprocessor (e.g., "1-2") for 1

second on initial power up after the "888" is displayed.

3. Actual tip temperature of the connected handpiece during normal operation. The tip

temperature displayed will flash when the system is in Temperature Setback.

4. The displayed temperature will decrease and stabilize at 177°C (350°F) when the

system is in Temperature Setback.

5. "OFF" when the Set Tip Temperature has been set to Off (below minimum set tip

temperature). Refer to the "Programming Your System" portion of this manual.

6. "OFF" plus the LED Display will be flashing when the unit has entered Auto Off.

Refer to the "Programming Your System" section of this manual.

7. Error messages ("OSE" or “CEE”) if a system fault is detected. Refer to the

"Corrective Maintenance" portion of this manual.

LED Display, Temperature Adjust Mode

The LED Display will show the following when adjusting the desired Set Tip Temperature.

1. The Set Tip Temperature.

2. "HiL" (High Temperature Limit) when adjusting the set tip temperature and the

maximum allowable temperature is exceeded. Refer to the "Programming Your

System" portion of this manual.

3. "OFF" (Low Temperature Limit) when adjusting the set tip temperature and the

minimum allowable temperature is exceeded. Refer to the "Programming Your

System" section of this manual.

3. "EP" will be displayed if a Set Tip Temperature adjustment is attempted and a

Password has been stored in system memory. As the Password is entered, the

display will change to the Set Tip Temperature if the entered Password matches the

stored Password.

5. "no" will be displayed if the entered password does not match the stored Password.

Temperature Setback Mode

To preserve tip life and save energy, the TW 100 system can be programmed to automatically set back its

Tip Temperature to 177°C (350°F) after a selected period of handpiece inactivity. The LED Display will

blink “177” or “350” depending on the selected temperature scale. As received from the factory, this

feature is enabled. Refer to the “Programming Your System” section of this manual to disable or adjust

the time-out period of this feature. The operator can also force the system into Temperature Setback.

Activating Temperature Setback:

There are two ways to activate the Temperature Setback feature.

1. AUTOMATIC ACTIVATION: The system can be programmed so that this feature will

automatically activate after a pre-selected period (10-90 minutes) of handpiece inactivity.

See the “Programming Your System” section for details on programming this feature.

2. MANUAL ACTIVATION: The operator can manually force the system into Temperature

Setback by performing the following procedure.

a. Press and hold the Scroll Down (

▼

) Key and the Scroll Up (

▲

) Key.

b. Release both keys.