48

Figure 8

Figure 7

TROUBLESHOOTING (cont’d)

If “Err” appears in the incline display after attempting an elevation change, the control panel did not see elevation movement. Touch the

incline Up or Down button and an “E 217” will appear in the Data Window. Check the wiring connection between the elevation motor and

the power supply. Check the elevation fuse to see if it has blown. If the fuse has blown, replace fuse.

Hesitation of the Tread belt

Hesitation of the tread belt usually indicates slippage of either the tread belt (the belt you walk on) or the drive belt (the belt connecting the

drive roller to the motor). To determine which of these belts is slipping, first adjust the drive belt tension and test to see if the slippage

stops. If the hesitation is not corrected than the tread belt tension needs adjustment.

CAUTION: Unplug your treadmill before attempting any cleaning or maintenance.

Drive Belt Tension Adjustment

Step One:

Use a Phillips head screwdriver to remove the 2 screws that hold the front of the

motor cover in place and remove the motor cover.

Step Two:

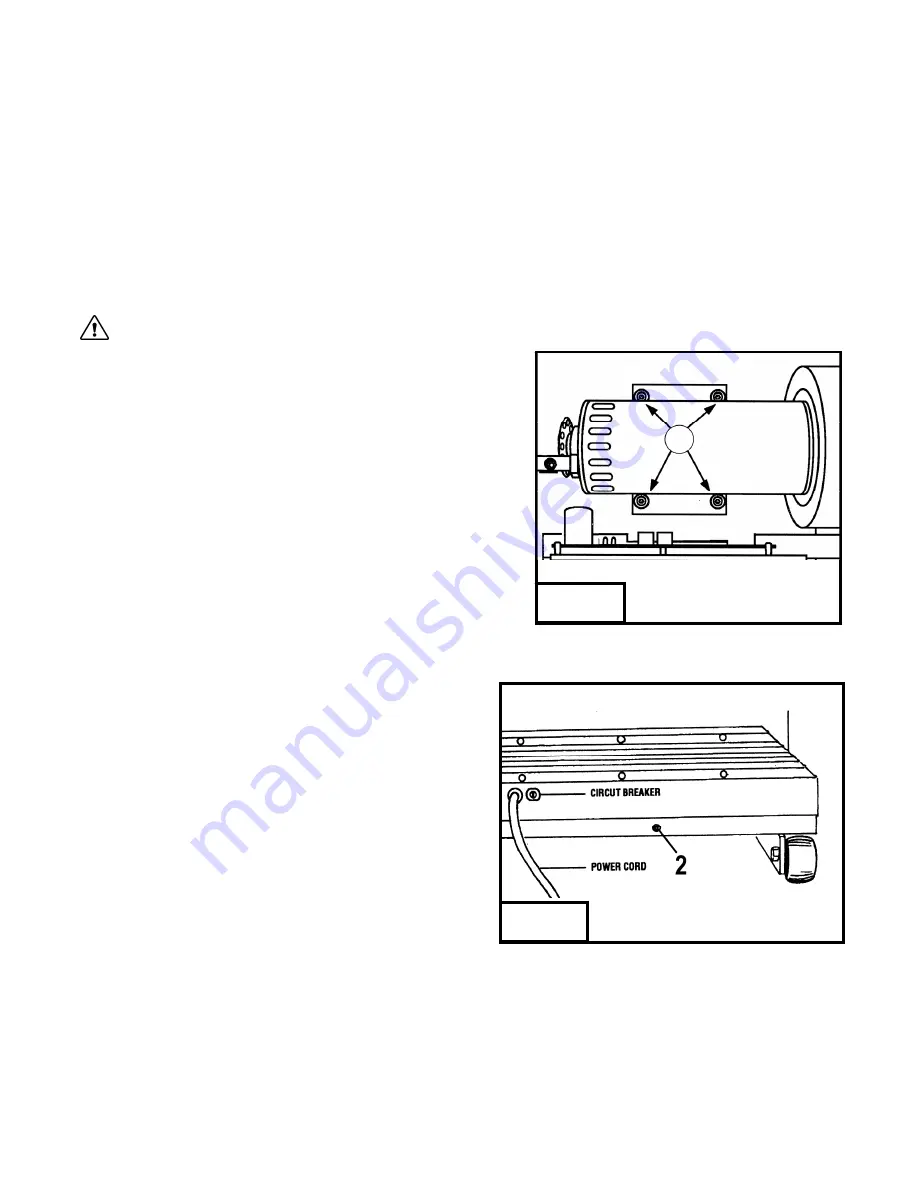

(figure 7)

Locate the four motor mount screws (item 1 in fig 7) as shown in the diagram

and loosen them each two turns each using the 3/16" Hex wrench.

Step Three:

(figure 8)

Locate the drive belt adjustment screw (item 2 in fig 8) in the lower

front end of the treadmill. Insert the Hex wrench into the drive belt

adjustment screw and turn the screw 1/2 turn clockwise.

Step Four:

(figure 7)

Complete the adjustment by tightening the four motor mount

screws (item 1 in fig 7).

Step Five:

Walk on the treadmill to determine if the slippage is decreased or

eliminated.

Step Six:

If no improvement is observed, the hesitation may be caused by a loose tread belt - see "Tread belt tension adjustment" below. If

improvement is noticed but slippage is still present, repeat steps 2 through 5. If you tighten the drive belt adjustment screw 1 1/2 turns and

there is still hesitation (slippage) contact your authorized PaceMaster dealer. Tightening the drive belt adjustment screw more than 1 1/2

turns can result in bearing damage to the motor and/or drive roller.

1