23

SPND.BODYA 161009-24

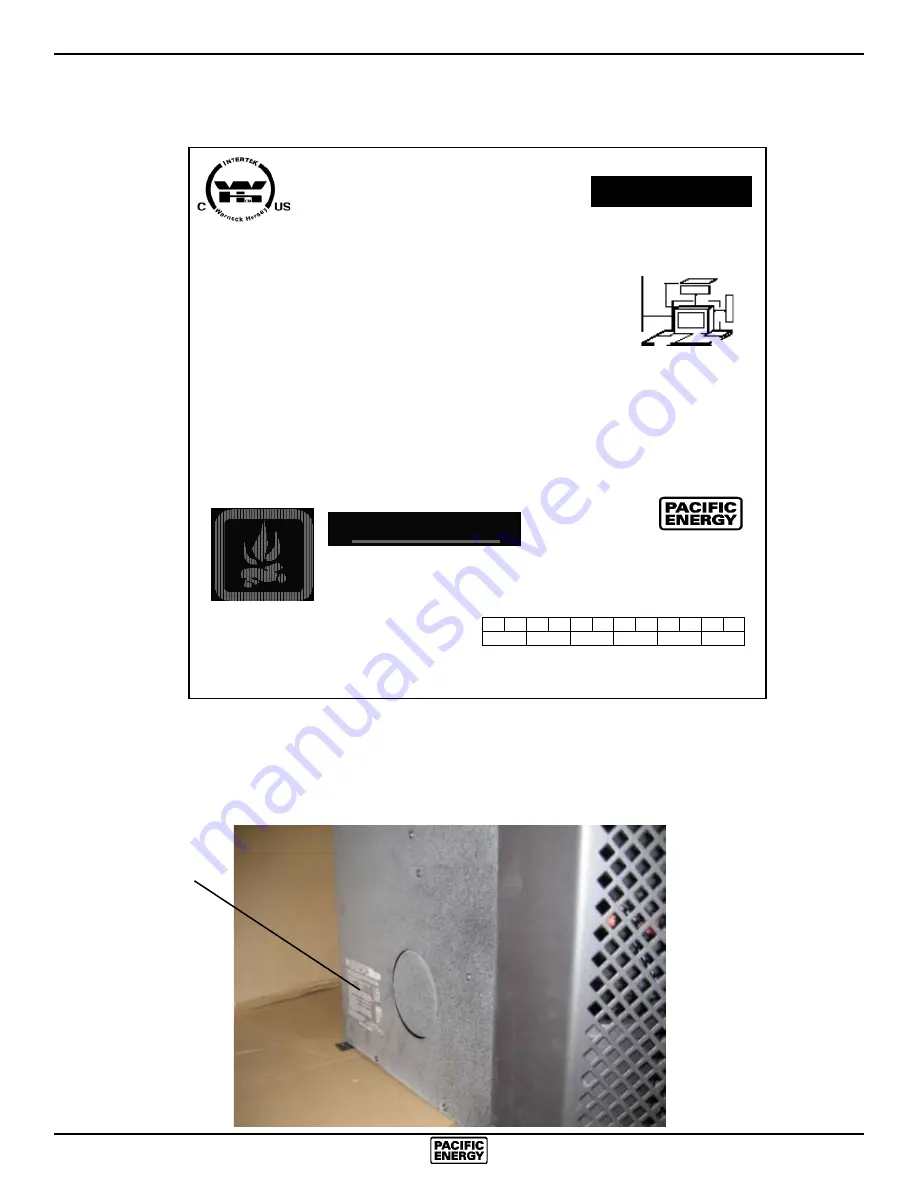

Label

MINIMUM CLEARANCE TO COMBUSTIBLES (MEASURED FROM INSERT BODY)

A)

ADJACENT SIDEWALL

520 MM / 20.5 IN

B)

MANTEL

762 MM / 30 IN

MANTEL WITH SHIELD 533 MM/ 21 IN

C)

TOP FACING

610 MM / 24 IN

D)

SIDE FACING

165 MM / 6.5 IN

INSTALL AND USE ONLY IN ACCORDANCE WITH THE MANUFACTURER’S INSTALLATION AND OPERATING

INSTRUCTIONS / INSTALLEZ ET UTILISEZ SELON LES INTRUCTIONS D'INSTALLATION ET D'OPÉRATION DU FAB-

RICANT. INSTALL AND USE ONLY IN MASONRY OR FACTORY BUILT FIREPLACE. DO NOT REMOVE BRICKS OR

MORTAR FROM MASONRY FIREPLACE.

DATE OF MANUFACTURE

INSTALL ONLY ON A NON-COMBUSTIBLE HEARTH RAISED 50 MM / 2 IN ABOVE AN ADJACENT COMBUSTIBLE

FLOOR. COMBUSTIBLE FLOOR BEYOND HEARTH MUST BE PROTECTED BY NON-COMBUSTIBLE FLOOR

MATERIAL EXTENDING 405 MM/ 16 IN TO THE FIRING SIDE (E) AND 200 MM / 8 IN TO THE OTHER SIDES (F) OF

THE UNIT / LE PLANCHER COMBUSTIBLE DEVANT LE FOYER DOIT ETRE PROTEGE PAR UN MATERIEL A L

EPREUVE DU FEU QUI EXCEDE DE 450MM/16" LE DEVANT DE L APPAREIL (E) ET DE 200MM/8" SUR LES COTES

(F). COMPONENTS REQUIRED FOR INSTALLATION / MATERIEL REQUIS POUR L INSTALLATION : FULL FLUE LINER

/ GAINE EN ACIER INOXYDABLE OR DIRECT FLUE CONNECTION ASSEMBLY. OPTIONAL COMPONENTS: MANTEL

SHIELD(SPND.MSMBKA), 3" VENT OFFSET(SPND.3OFFSETA), FAN KIT, ELECTRICAL RATING 115V, 60HZ, 1.6 AMP.

ROUTE CORD AWAY FROM UNIT. FOR USE WITH SOLID WOOD FUEL ONLY / POUR UTILISATION AVEC COMBUS-

TIBLE AU BOIS SEULEMENT. DO NOT USE GRATE OR ELEVATE FIRE-BUILD WOOD FIRE DIRECTLY ON HEARTH.

OPERATE WITH FEED DOOR CLOSED. REPLACE GLASS ONLY WITH CERAMIC GLASS / REMPLACES LA VITRE

AVEC UNIQUEMENT DE LA VITRE CÉRAMIQUE. INSPECT AND CLEAN CHIMNEY FREQUENTLY. UNDER CERTAIN

CONDITIONS OF USE, CREOSOTE BUILDUP MAY OCCUR RAPIDLY.

MADE IN CANADA

F

M

A

M

J

J

A

S

O

N

D

2009

2010

2011

2012

2013

2014

U.S. ENVIRONMENTAL PROTECTION AGENCY

CERTIFIED TO COMPLY WITH JULY 1990

PARTICULATE EMISSION STANDARDS

J

LISTED FACTORY BUILT FIREPLACE ACCESSORY INSERT

CERTIFIED FOR USE IN CANADA AND U.S.A.

TESTED TO / ÉPROUVÉ SELON:

ULCS628 / UL1482

MODEL / MODÈLE: SUPER INSERT

SERIES / SÉRIE: D

WN# 16407

CLEARANCE TO COMBUSTIBLE

CONSTRUCTION

F

ADJACENT SIDE W

ALL

010909

5050.74.B

SPND-1

A

B

D

E

C

CAUTION

HOT WHILE IN OPERATION. DO NOT TOUCH. KEEP CHILDREN,

CLOTHING AND FURNITURE AWAY. CONTACT MAY CAUSE SKIN

BURNS. SEE NAMEPLATE AND INSTRUCTIONS.

MANUFACTURED BY:

PACIFIC ENERGY FIREPLACE PRODUCTS LTD.

2975 ALLENBY RD., DUNCAN, BC V9L 6V8

F

The ceritfication label is located on the left side casing of the insert.

CERTIFICATION

LABEL

Summary of Contents for Super Insert DESIGN-D

Page 20: ...20 SPND BODYA 161009 24 NOTES...

Page 21: ...21 SPND BODYA 161009 24 NOTES...

Page 22: ...22 SPND BODYA 161009 24 NOTES...