- 12 -

SOLUTION DISTRIBUTION

FILLING THE SOLUTION TANK

SOLUTION FLOW

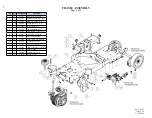

DRIVE SYSTEM

1. Turn the machine on using the key switch located on the right side of the steering column.

2. Set the desired maximum speed using the MAX SPEED selector on the Control Panel

3. Select the desired direction of travel using the FORWARD and REVERSE selectors on the Control Panel.

4. Maintain control of the Steering Wheel at all times during operation.

5. Depress the Throttle Pedal to engage the drive system.

NOTE

: The speed of the machine is based on the relative amount the throttle is depressed. The MAX SPEED selector governs the

maximum speed the machine will travel with the throttle fully depressed.

NOTE

: The machine is equipped with a sensor which reduces the maximum speed while in sharp turns. After the steering wheel is

straightened, the machine will return to the full maximum speed as regulated by the MAX SPEED selector.

The machine can be moved manually (pushed or pulled) if absolutely necessary. Before attempting to move the machine manually,

fully actuate the Manual Brake Release located on the right side of the Drive Wheel. The Manual Brake Release lever must be fully

actuated the entire time the machine is being moved. Failure to fully actuate the Manual Brake Release lever could cause damage to

the Drive Wheel and brake system.

Use liquid detergent in the concentration and manner specified by the manufacturer for a

30-gallon solution tank. Excess foam will damage the vacuum motor. In addition to properly-

mixed low-foam detergent, use a small amount of de-foaming liquid in the recovery tank. Never

use pure acids.

1. Add water and cleaning agent via the fill port located under the Seat Assembly. Water should

not exceed 120°F (50°C).

2. Monitor the level of the solution through the sight tube located on the side of the machine.

3. To drain the solution tank, slide the sight tube off of the upper fitting and lower the tube into

drain or mop sink.

Solution flow is controlled by the SOLUTION FLOW selector located on the Control Panel.

Solution is delivered at a rate of 0.1 - 0.8 gpm (0.005 - 0.037 kg/sec) based upon the SOLUTION

FLOW setting and the speed of the machine (flow rate increases or decreases with machine

speed to prevent over/under distribution).

When the machine senses that the solution tank is empty, the SOLUTION EMPTY LED

will illuminate and the scrub head will turn off.

Summary of Contents for RS28

Page 23: ...20 RETURN TO TABLE OF CONTENTS PAGE INTENTIONALLY LEFT BLANK...

Page 43: ...RETURN TO TABLE OF CONTENTS 40 PAGE INTENTIONALLY LEFT BLANK...

Page 52: ...49 RETURN TO TABLE OF CONTENTS ELECTRICAL DIAGRAMS...

Page 53: ...RETURN TO TABLE OF CONTENTS 50 ELECTRICAL DIAGRAMS...

Page 54: ...RETURN TO TABLE OF CONTENTS 51 DATE MAINTENANCE LOG...

Page 55: ...52 RETURN TO TABLE OF CONTENTS DATE MAINTENANCE LOG...

Page 57: ...54 RETURN TO TABLE OF CONTENTS PAGE INTENTIONALLY LEFT BLANK...

Page 58: ...www pacificfloorcare com...