- 6 -

SERVICING LEAD ACID BATTERIES WITH HYDROLINK

®

WATERING

SYSTEM

1. Position the container of distilled water below the level of the top of the batteries to prevent siphoning.

2. Place the end of the watering system hose in the distilled water and squeeze the bulb to fill the system.

3. Remove the dust cover from the Hydrolink

®

snake connected to the batteries.

4. Connect the coupler on the Hydrolink

®

snake to the coupler on the watering system using the quick disconnect fittings.

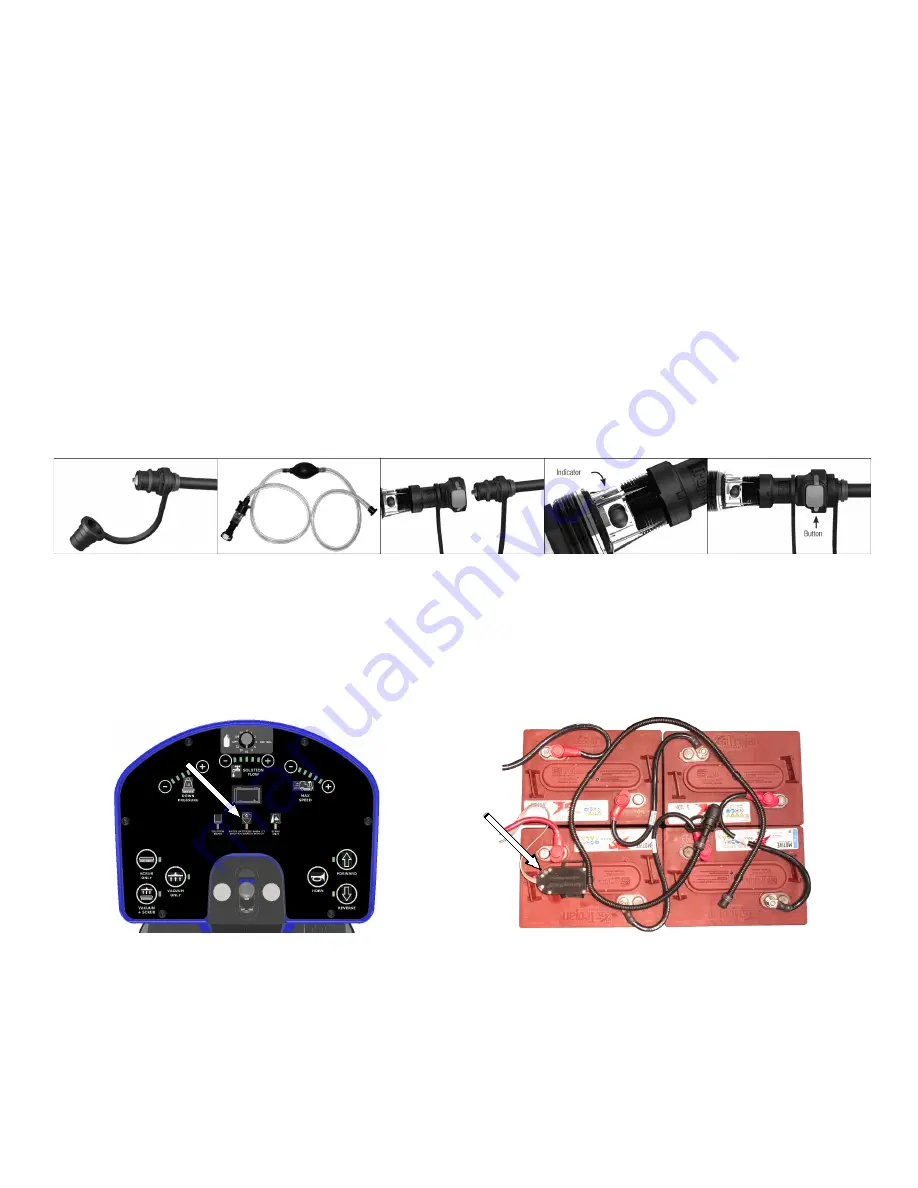

5. While squeezing the hand pump, observe the flow indicator (spinning red balls). As the batteries begin to fill, the spinning of the

flow indicator balls will slow. Batteries are full when the flow indicators completely stop spinning.

NOTE

: Battery systems may take more than 1/2 gallon of water once the BatteryShield

®

light has illuminated. Failure to actuate the

hand pump until the flow indicator stops spinning will result in batteries being under or unevenly serviced which will reduce

battery life.

6. When the flow indicator stops, and not before, disconnect the coupler by depressing the push button on the watering system

coupler.

NOTE

: Leaving the watering system connected could result in the batteries being over filled. Disconnecting the watering system

before the flow indicator stops spinning will result in batteries being under serviced and battery life will be reduced.

7. Replace the dust cover on the Hydrolink

®

snake.

BATTERYSHIELD

®

AUTOMATED WET BATTERY PROTECTION

SYSTEM

Machines equipped with BatteryShield

®

technology have a sensor installed on one of the battery caps and a red LED indicator located

on the Control Panel. This sensor monitors the water level in the batteries and the LED communicates to the operator that the batteries

require servicing. When the BatteryShield

®

LED is lit, the scrub head is disabled until battery servicing has been performed.

•

When the key switch is turned on, the BatteryShield

®

system will check the water level of the batteries.

•

If the LED turns off, there is sufficient water in the batteries.

•

If the LED remains on (without flashing), the batteries require servicing and the scrub head will not run.

•

If the LED flashes intermittently, the BatteryShield

®

light pipe must be cleaned (instructions below).

NOTE

: Failure to clean the BatteryShield

®

light pipe will limit the system’s ability to read the water level and will reduce battery life.

•

If the BatteryShield

®

LED indicates the need for servicing, turn off the key switch and service the batteries as described above.

•

After completing the Hydrolink

®

watering system procedure, turn the key switch back on and verify the LED turns off.

Summary of Contents for RS28

Page 23: ...20 RETURN TO TABLE OF CONTENTS PAGE INTENTIONALLY LEFT BLANK...

Page 43: ...RETURN TO TABLE OF CONTENTS 40 PAGE INTENTIONALLY LEFT BLANK...

Page 52: ...49 RETURN TO TABLE OF CONTENTS ELECTRICAL DIAGRAMS...

Page 53: ...RETURN TO TABLE OF CONTENTS 50 ELECTRICAL DIAGRAMS...

Page 54: ...RETURN TO TABLE OF CONTENTS 51 DATE MAINTENANCE LOG...

Page 55: ...52 RETURN TO TABLE OF CONTENTS DATE MAINTENANCE LOG...

Page 57: ...54 RETURN TO TABLE OF CONTENTS PAGE INTENTIONALLY LEFT BLANK...

Page 58: ...www pacificfloorcare com...